"Now as for the legality of what you use this for... I personally only reproduce products with direct permission of the person who made them or that I have made myself. In my mind it is just the same as stealing when you replicate or reproduce to sell. Some of these products take time to make and people expect to make some cash at it or they wont do it any more. However, there are no laws that I am aware of that prevent you from cloning a product for yourself but, there are ones out there to prevent you from reselling the same product especially when a copyright violation is involved."

Now that I have reiterated that let us begin.

This DIY session is geared twords showing the average Joe how to make a mold and then cast it. There are higher quality products and better methods out there but this methods will get the job as simply as possible.

The first task is going to be gathering supplies. Keep in mind that the quantities I bought my supplies in are not the only ones available. Many companies offer smaller quantities down to a pint. I just happen to go through alot of the stuff so I order enough so that I use it all before it goes past expiration. Getting fresh product is also essential. If possible I only buy factory direct when selecting a rubber or resin. When you deal with 3rd parties you cant guarantee that the product hasn't been sitting on a shelf for the last year or two. Its your money spend it wisely. If you hate money... pm me and ill send you my paypal information.

Here is a short list of everything I have selected for this walk through. More will come up later and I will make sure to mention it.

1. Resin- Alumilite RC-3 1 gal kit -$105.00 http://www.alumilite.com/" onclick="window.open(this.href);return false;

I like this stuff because it mixes 1:1. There is no fancy math involved. I also like this stuff over the standard line they have because, it has a pot life of 3 min compared to 90 sec. Another benefit is the stuff is so close to water in viscosity that it degases a bit better and gets into those detail part well. The stuff is also wonderful to machine.

Mix Ratio (wt. or Vol.) 1:1

Pot Life 3 min.

Demold Time (100 gr. Mass) 5-15 min

Mixed Viscostiy (cps.) 110

Shore Hardness 74 D

Shrinkage (in./in.) .004

2. Rubber- OOMOO® 30 - Shore 30A hardness 1 gal unit - $145.74 http://www.smooth-on.com" onclick="window.open(this.href);return false;

Where to begin with rubber or more accurately silicone. There are two types of silicone I use, platinum cure silicone and tin cure silicone. Platinum cure last longer, doesn't deform as bad and can handle much higher temperatures. The down side is that it cost a lot more and it can be sensitive to paints, latex, etc leaving a gooey incurable mess where it contacted it. Tin on the other hand can be very forgiving regardless of what you pour it on. It will deform over time due to stretching and such but its cheaper cost helps out there. Omoo 30 also degases very well which means you can get away with not molding in a pressure pot, huge bonus for the hobby modeler. For those of you that are curious when I buy the good stuff I like to buy bjb tc 50-50. It is amazing silicone. Ive seen ancient molds that are still in service. When selecting a shore hardness I usually get at least a 30 - 50a. Softer is better for more intricate details but the hard stuff is more durable.

"OOMOO® 25 & 30 are easy to use silicone rubber compounds that feature convenient one-to-one by volume mix ratios (no scale necessary). Both have very low viscosity for easy mixing and pouring, and vacuum degassing is usually not necessary. Both products cures at room temperature with negligible shrinkage and have good tear strength. "

A:B Mix Ratio 1:1 by volume

Demold Time 6 hours

Pot Life 30 min.

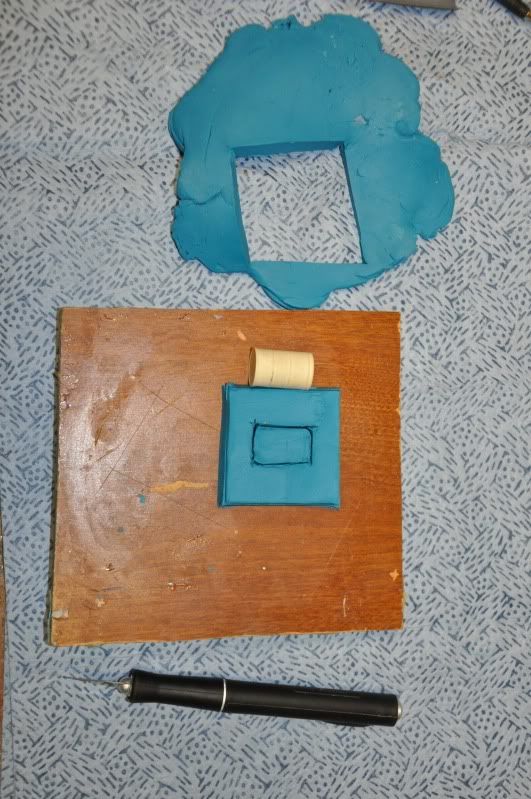

3. Molding Clay- Klean Klay 1lb- $8.25 http://www.kleanklay.com/" onclick="window.open(this.href);return false;

Remember how I said some silicones were sensitive? Well that is another reason I stick with Klean Klay. I know without a doubt that it is sulfur free clay. Sulfur = nasty gooey molds. Besides that, the stuff isn't to rock hard at room temp. I still like to knead my clay a bit to soften it up before I get to work anyway. Kind of like prepping to clay bar your car.

"Art Chemical Products produces non-drying, non-hardening, no-sulfur modeling clay for a variety of applications. It is non-toxic, sanitary, and odorless. Klean Klay is easy to handle and work with and remains hand-pliable at room temperature. Klean Klay keeps its smooth, firm consistency and retains the shape into which it is molded. "

4. Mold Release- Mann 200- $11.49 http://mann-release.com/erelese2.htm" onclick="window.open(this.href);return false;

Comes in an spray an its easy to apply. Why use it though? Nothing sticks to silicone except silicone right? It will help with separating your parts from the mold extending the service life of your molds.

"General purpose mold release that works with silicones and urethane mold making rubbers. Will release urethane, epoxy and polyester resins from a variety of surfaces."

5. Mixer- Turbine Mixer- $11.30 http://www.smooth-on.com/gallery.php?ga ... cPath=1221" onclick="window.open(this.href);return false;

Ok you dont really need this but, I love it . It does a wonderful job and doesn't aerate the silicone to much. On a serious note Ive used a tongue depressor to a model boat prop on a shaft and been just fine.

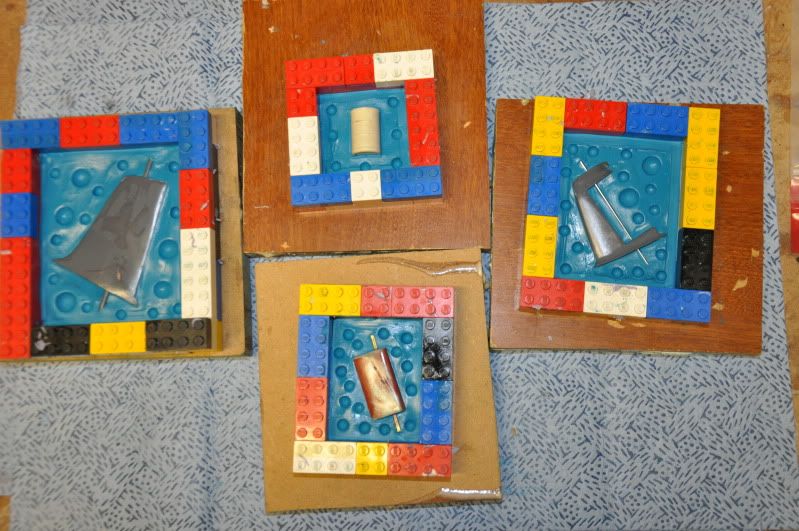

6. Mold Housing- Legos- $? Anywhere in the world

These little engineered blocks are great for molds. They always fit together in perfect shapes that can be reproduced easily. You could cut out forms using plastic or wood but then you have to get it all square so that when you flip the mold over it still fits in the jig.

7. Mixing Cups - Disposable cups

Buy a big pack and never worry about it again.

8. Resin mix sticks

I buy these by the 1000 at the local crafts store. I use them alot. Its basically wood Popsicle sticks

9. Scale

It doesnt have to be ultra sensitive. To the first decibel at least. Technically you dont need this as everything here is 1:1 by weight or volume.. I find weight is easier.

10. Glove- Nitrile based

The use of latex glove will give you a gooey mess when dealing with platinum rubber. Dont bother with latex just get the good stuff.

Well thats not everything but the other stuff I will cover is kind of optional so it will be covered in the next installment when I write it tomorrow night. Id give it to you all in one go but this stuff takes time to write! Tanks Guys