I tried the STL import thing in Openscad. It doesn't give you an editable file, it simply imports the whole thing with one command. What I had to do was use it as a template to build the part that I wanted around it, eg holes in the correct place and correct diameter. Then comment out the import code so that i was left with the part that I designed. In this example I imported two of the printer parts, aligned them, and then designed a new part that was one piece.

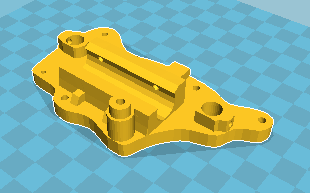

Printer part 1:

- Screenshot from 2017-01-31 09-09-42.png (8.01 KiB) Viewed 821 times

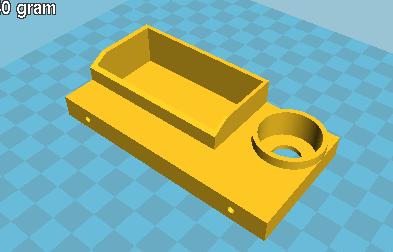

Printer part 2

- Screenshot from 2017-01-31 09-10-12.png (11.34 KiB) Viewed 821 times

New part above:

- Screenshot from 2017-01-31 09-08-55.png (11.54 KiB) Viewed 821 times

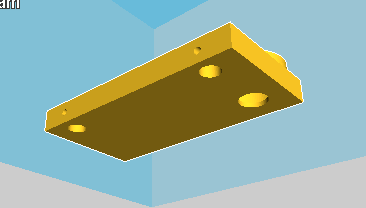

New part underneath:

- under.png (3.95 KiB) Viewed 821 times

Printed new part:

The way to do it is :

//module antiwobble()

//{

//import("/home/rob/Desktop/Smartrap Parts/RELEASE/antiwobble_support 8mm.stl");

//}

//

//module base()

//{

//import("/home/rob/Desktop/Smartrap Parts/RELEASE/plate_base.stl");

//}

module topsteady()

{

$fn=100;

difference()

{

union()

{

translate([-45,-66,17])cylinder(14,14,14);//bearing outer case

translate([-59,-80,17])cube([100,50,10]);//base plate

translate([-26,-80,23])cube([67,35,15]);//tools

}

translate([28,-37.5,4])cylinder(20,4.1,4.1);//rod hole

translate([-45,-37.5,4])cylinder(20,4.1,4.1);//rod hole

translate([-45,-66,0])cylinder(50,6,6);//thread hole

translate([-45,-66,19])cylinder(14.1,12,12);//bearing inner

translate([-24.5,-78,24])cube([63,31,15]);//tools

translate([-30,-77,52])rotate([-30,0,0])cube([75,37,15]);//tools slope sides

translate([28,-26,22])rotate([90,0,0])cylinder(10,1.5,1.5);//clamp screw hole;

translate([-45,-26,22])rotate([90,0,0])cylinder(10,1.5,1.5);//clamp screw hole;

translate([-9,-62.5,20])rotate([0,0,0])cylinder(20,16,16);//pritt stick

}

}

topsteady();