Just thought I would show the work I have done so far in my 1/6th scale Abrams tank build.

This is an all metal build.

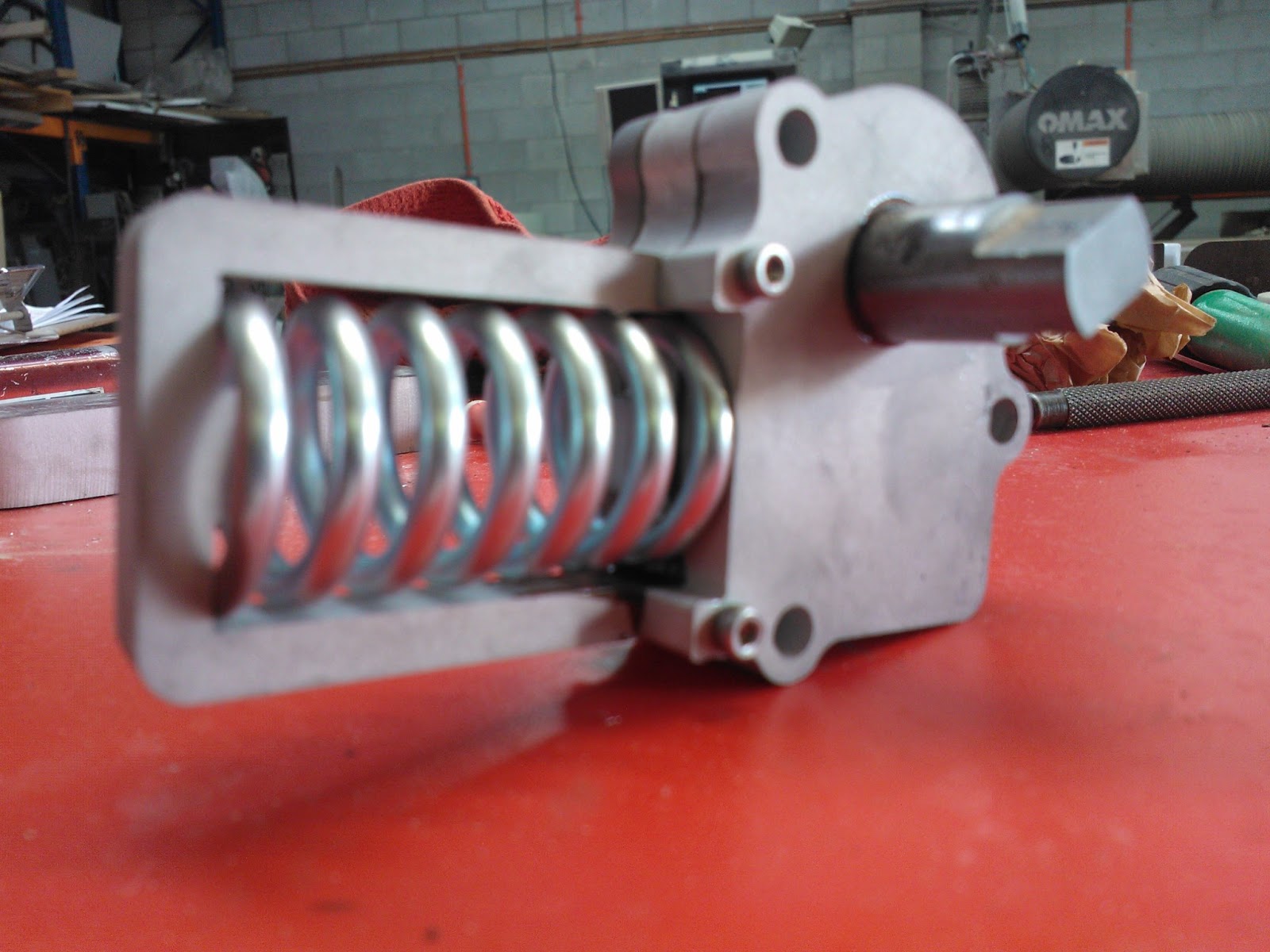

This is the suspension units I am making for each road wheel, they are capable of carrying 16kg's each so should hold up the expected 150kg end weight of the project

This is the main chassis of the tank, its cut out of 4mm Mild Steel

The cassis starting to get welded together

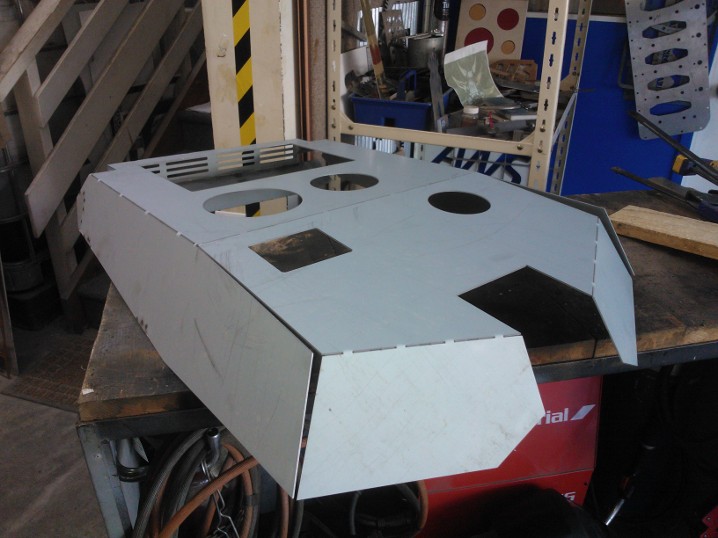

Couple of pics of the turret skin cut from 1.6 Mild Steel (the 1mm I originally used was to thin)

The base and top of the turret, the base is 2mm Mild Steel

Couple of shots where im sizing everything and checking clearances

All primed up and stored in the workshop

Now I have to make the tracks out of 6mtrs of 2060 chain. fabricate the suspension units and build the road wheels etc

If you interested in more have a look at my build log at the address below, I will be updating this with progress

http://spudnik1970.blogspot.co.nz/

Grant