That is also what I have read as a general consensus on why the steel wheels were not introduced into full production.

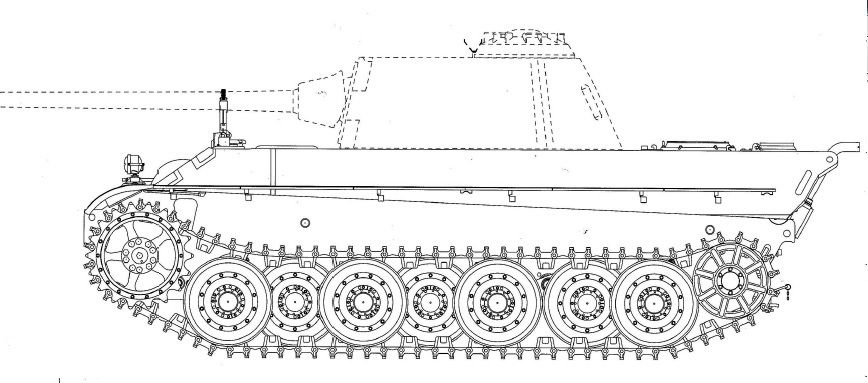

As my version will be a November '45 build and carry the rockets, there will be a level of theoretical allowance given.

Hypothetically, and without the benefit of metallurgical info or service testing results, the steel wheels had a resilient edge(the outer edge of the rim/tyre) that would have at times run on the root of the guide horn and that would have been a similar composition to spring steel.

I contend that only after time and all aspects of the appropriate stresses had been introduced into the root of the guide horn that failure would have occurred.

How long was required exactly - who knows, but at this stage of the conflict, and losses being so heavy and immediate, how reliable was the failure rate data, and over what number of the 24 produced were confirmed to have suffered a higher track/running gear failure rate than the rubber tired equivalent ?

I can't accept that a run of 24 machines was commissioned to be 'lab-rat' test vehicles when to prove or disprove the feasibility of the running gear, any and all failures would have to be recorded & details sent back to the factory for analysis in order for any results to be considered accurate.

This is assuming the units recorded track throw rates = vehicle availability for combat across the entire division ..............

I reckon the wheels were a first go at standardisation of production across models of vehicles, at least as far as the high attrition consumables hardware goes (tracks, wheels & barrels)and this factory was the quickest to adapt production & assembly to the task.

Or, they had the hardware to hand & came up with a way of using it.

We will never know for sure either way.

With this in mind I test ran my rolling chassis today

Over kids toys, my foot(just to see how it felt !) and all manor of obstacles.

Ran like a Gypsy with a mortgage document

...............

Also had a few moments before getting dragged out for a haircut & drinks, so hooked into the hull with a borrowed miracle of the modern world.....................

A RENOVATOR

Its a gadget that takes many attachments, but the one I used was the triangle sander

Smashed the Tamiya putty off the hull without raising a sweat.

But Jezzus did it make dust

All I need to do now is coat the plates in super glue, finger them over, and voila- textured steel.

I am going to get me one of these things for sanding, that like death, gravity & taxes is a certain destiny

HL JAGDPANTHER,HL TIGER 1,HL PzIII MUNITIONSCHLEPPER, HL KT OCTOPUS,HL PANTHER ZU-FUSS,HL STuG III,HL T34/85 BEDSPRING,

HL PZIV MALTA,MATORRO JAGDTIGER,HL F05 TIGER,TAMIYA KT,HL PANTHERDOZER,HL EARLY PANTHER G,TAIGEN/RAMINATOR T34/76,

HL AN-BRI-RAM SU-85