Page 4 of 9

Re: Two fender-less Tigers

Posted: Wed Jan 17, 2024 10:01 pm

by jarndice

Shapeways is one source for the Tiger 1 Late Loaders hatch.

Fender-less Tiger I

Posted: Wed Jan 17, 2024 11:23 pm

by Ecam

Thanks Jarndice! First go at German armor, still have a ton to learn.

Fender-less Tiger I

Posted: Sun Jan 21, 2024 8:29 pm

by Ecam

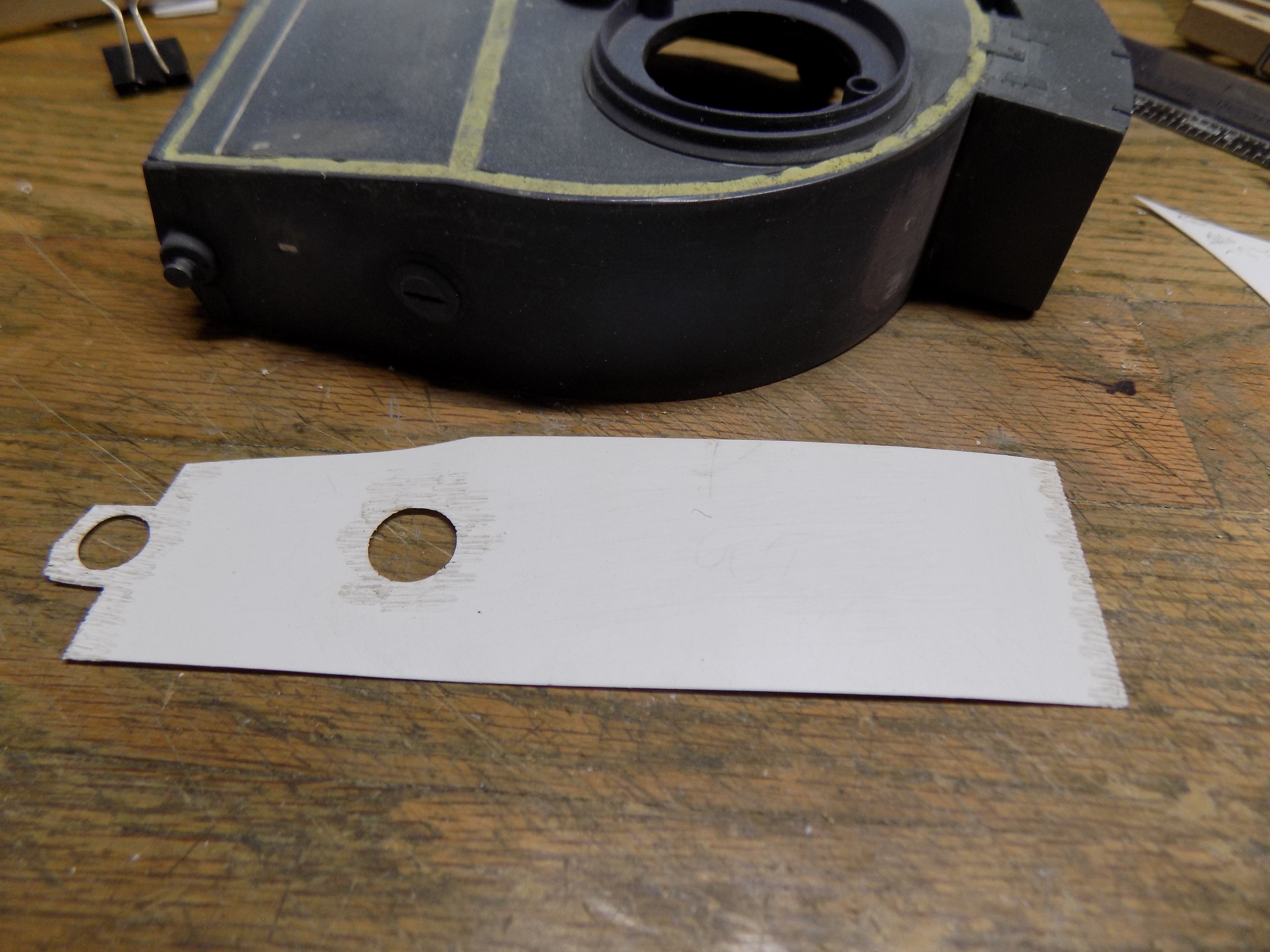

Looking for honest opinions. Passable for a first time zimmerit job? Don't worry, no one nearby to see me sob.

- 22.JPG (1.22 MiB) Viewed 205 times

- 23.JPG (1.29 MiB) Viewed 205 times

Re: Two fender-less Tigers

Posted: Sun Jan 21, 2024 8:48 pm

by Ad Lav

Looks good that!

Re: Two fender-less Tigers

Posted: Sun Jan 21, 2024 9:45 pm

by HERMAN BIX

Mighty good I reckon

Re: Two fender-less Tigers

Posted: Sun Jan 21, 2024 10:54 pm

by MrChef

I only hope my zimmerit will come out as good as yours for my mid war build.

Nice work Eric

Fender-less Tiger I

Posted: Sun Jan 21, 2024 11:26 pm

by Ecam

Re: Two fender-less Tigers

Posted: Mon Jan 22, 2024 1:41 am

by Jimster

That’s incredibly cool looking. Hats off to you.

Fender-less Tiger I

Posted: Mon Jan 22, 2024 4:30 am

by Ecam

Ok that's enough for a Sunday evening. I'll work on the hull sides and rear panel tomorrow. Notice I only did the areas that would be difficult to emboss when glued on.

- 29.JPG (1.08 MiB) Viewed 203 times

- 30.JPG (1.48 MiB) Viewed 203 times

Re: Two fender-less Tigers

Posted: Mon Jan 22, 2024 8:41 am

by HERMAN BIX

And I reckon Winches and cables that function are Masochistic!!!

Great job Mr Ecam, hardest part of the melting plastic method is to keep the heat up on the material so the plastic doesn't respond like Mozzarella cheese & string everywhere.