Page 4 of 10

Re: Russian SU76M

Posted: Sat Aug 19, 2017 6:00 pm

by wibblywobbly

You are not the only person who learns something new every day, I never knew that!

Re: Russian SU76M

Posted: Sun Aug 20, 2017 9:19 am

by wibblywobbly

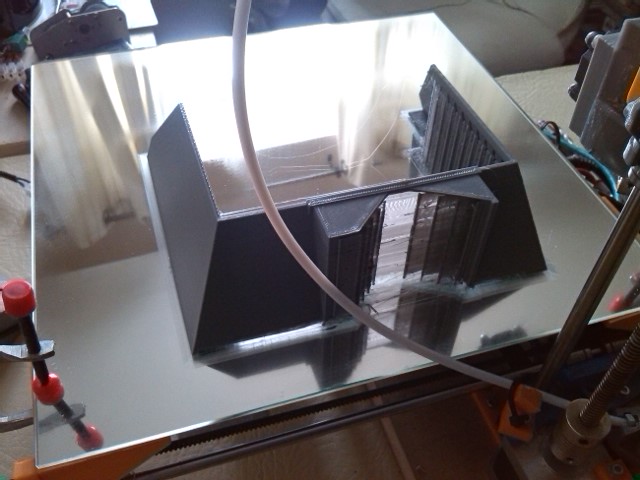

Jeez, Cura told me it was a 6 hour print job, I had already had one failed print, so had to spend time dismantling the hotend and de-clogging it. Time was running out...

I started the print again, and ramped up the print speed by 25% thinking that would knock an hour off at least. Six and and half hours later, and well past midnight, it finished. Thank Christ this one turned out as nature intended.

- IMG_20170820_075624.jpg (87.28 KiB) Viewed 3211 times

And added to the pile of parts.

- IMG_20170820_084109.jpg (61.72 KiB) Viewed 3211 times

I can now get on with the onerous task of designing the gun, and the rear interior, which is a lot of detail work, I need new glasses!!

Re: Russian SU76M

Posted: Sun Aug 20, 2017 10:46 am

by AlwynTurner

Great progress Rob

, the print time for flat parts is why I prefer to use styrene sheet, my nerves and intestinal fortitude could not withstand a six hour print

especially given my recent printer experiences.

Will continue watching the progress with great interest.

Alwyn

Re: Russian SU76M

Posted: Sun Aug 20, 2017 10:54 am

by 43rdRecceReg

wibblywobbly wrote:All printers can print in either ABS or PLA. If you use ABS you have to use the printed bed, but with PLA you can print on a glass bed, I use a £1 Ikea mirror and hairspray.

The nozzle diameter is important, some ABS printers use 3mm filament, PLA is 1.75mm, but they can be swapped in minutes.

I can't believe you have a printer and haven't switched it on yet? I think thats the same one that Alwyn has, and apart from a few minor set-up niggles he gets excellent results.

This lad makes very entertaining and informative videos on 3D printers.

yes..but I'm building a Tamiya KT at the moment,

and trying to finish my Cromwell too. I'm afraid I don't do that much multi-tasking well these days. The other reason is that I really don't have anywhere to put it (safely), where I can connect it to my iMac.

I'll have to buy, or assemble some alternative arrangement. Currently my Mac (at 27"..it's already a space-hogger itself

) sits atop a bespoke computer table with my Canon printer, speakers and external Blu-Ray burner...as well as a Panzer IV for company. There's not an inch of space on it, or around it, to accommodate the Hictop- yet, anyway. Then there's the issue of the 32-bit 'Cura' software that came with it. Mac OS doesn't like it. In fact, with the next update to Mac OS, no 32-bit applications will work at all. It will be exclusively a 64-bit system.

Ahh well. Finally, I couldn't see the point of opening up a filament roll and installing it, because they're only supposed to be good for a week or so, and it would be wasted, as I've no idea of what to print at the moment. Yes, I'll have to check it out soon, just to make sure that it does work (guarantee issues etc...) and so I'll sort it eventually. Meantime, it's back to the tanks.

Don't want to sound ungrateful for such a generous present; but the timing could have been a little better. However, I will check the videos out, and thanks for that!

I have visitors for the next few weeks , though, so much of this will go on the fabled

'back burner'....

Re: Russian SU76M

Posted: Wed Aug 23, 2017 9:23 am

by wibblywobbly

Ahh well. Finally, I couldn't see the point of opening up a filament roll and installing it, because they're only supposed to be good for a week or so,

My PLA often sits on the spool next to a printer for weeks, if not a month or more, it doesn't affect it at all. I wouldn't worry about that.

Back to the build...

Designed the muzzle brake, barrel and mantlet. Took a bit of figuring out, but I got there in the end. Have now run out of filament on the printer I am using for large parts, so can't print the lower hull for a few days.

Re: Russian SU76M

Posted: Wed Aug 23, 2017 11:36 am

by Raminator

Impressive bit of drafting there, Rob. I've had a crack at OpenSCAD, but the parametric-driven nature goes right over my head since all of my experience is with CSG-based modelling. I'll have to try something else if I want to give these 3D-printing shenanigans a try.

Son of a gun-ner wrote:wibblywobbly wrote:You are not the only person who learns something new every day, I never knew that!

If you're referring to the ratio of gear teeth to diameter. You didn't really learn anything new.

I've got a confession, it's just basic maths, the ratio of the circumference to the diameter of a circle, it's what Pi is. So, if you did maths at school, you already knew it lol.

The only way it works with gears is when the pitch of the teeth is always the same, as in same profile.

Mick.

That makes two of us that learned something new, it had never occurred to me. Much appreciated Mick, I feel smarterer already!

Re: Russian SU76M

Posted: Sun Aug 27, 2017 8:32 pm

by wibblywobbly

Apart from an averted catastrophe half way through the mantlet print, it is coming together. The barrel, mantlet, mantlet inner, muzzle, breech and shell loading tray are now all done. It's killing my eyes doing all these small parts, and staring at the screen. I need new glasses but I am too tight to buy them and can't be a**ed to drive to the opticians.

Waiting for a couple of bit and pieces to arrive and then I can start the lower hull, I may yet just print the sides, and make the base out of 3mm styrene. It's a 32 hour print otherwise for a complete lower...

I have started to design the tracks, just as an experiment, I'll see how that goes...

Re: Russian SU76M

Posted: Sun Aug 27, 2017 8:34 pm

by c.rainford73

That is awesome Mr Wibbly

very very talented with that 3D printer for sure!

Re: Russian SU76M

Posted: Sun Aug 27, 2017 9:16 pm

by AlwynTurner

Re: Russian SU76M

Posted: Sun Aug 27, 2017 9:30 pm

by wibblywobbly

Amazingly little coding, I am learning how to apply my old programming skills to Openscad, using loops, and hull commands etc I am also getting into looking at a photo, and converting the shapes into Openscad in my head, and at the same time visualising how to orientate parts to get a clean print and so on.

I never stop learning, it keeps my brain active.

very very talented with that 3D printer for sure!

very very talented with that 3D printer for sure!