Nic

gawd , another Tiger 1 (late) w.i.p. yawn . . .

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Hi Blimp, I like the intake mod...like a lot!

Nic

Nic

- majordisastor

- Lance Corporal

- Posts: 208

- Joined: Fri Apr 23, 2010 5:24 pm

- Location: Llantrisant, South Wales

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Nice mod, clean and well done with scope for further expansion.....Text book stuff - well done

Andy

Andy

It always gets darkest before it goes completley black......

- blimp

- Sergeant

- Posts: 745

- Joined: Sat Dec 11, 2010 12:29 am

- Location: Watford , NW Londonistan . U.K.

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

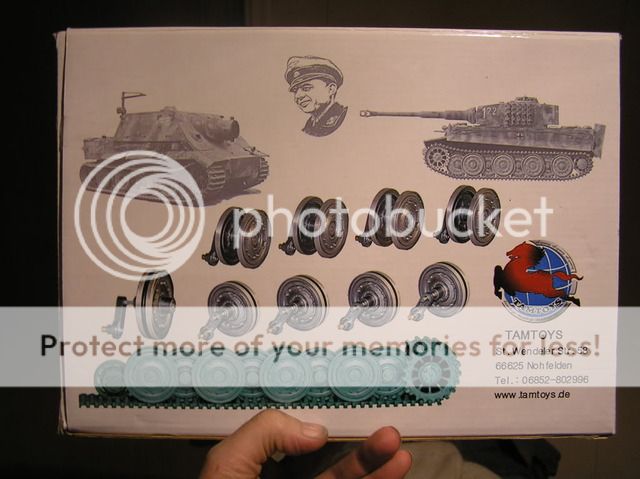

Onto the roundy bits then .

- . . . In the begining the decision to do a late version was made easier by the fact that although the H/L plastic wheels are capable of coping with this sort of chopping and changing , i just didn't like the tyre / rim detail . Too vauge , and i couldn't bother with filling the things , machining new profiles , etc.

- . . . * made in china .

- . . and a horrible , metallic , oily , SMELL almost knocked me off my feet . No joke , I quickly opened the windows as well .

- A coat of primer was applied as soon as i got the oppurtunity , it helped thankfully , - but i still take care not to scratch them .

- . . . it wasn't the only nasty suprise either , trying them on axles 5 out of 16 of them wobbled badly - due to poor finnishing , i had to true /skim / re drill 4 of them at work , bushing them with 3mm i/dia tube . the 5th one was so bad it needed a 5mm plug to get right

.

.

- Yipee . they now fit , O.K. a bit tight on the track shoe horns , but they do fit . Honest .

Last edited by blimp on Mon Apr 11, 2011 1:27 pm, edited 1 time in total.

to the bouncy room ! Yay !

- blimp

- Sergeant

- Posts: 745

- Joined: Sat Dec 11, 2010 12:29 am

- Location: Watford , NW Londonistan . U.K.

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

A new day , Ahh , the weekend is here , the sun is shining , last nights post brought the whole expierience back , but the nightmares will stop , so i'm told . Us H/L owners are made of sterner stuff y'know .

give yourself a pat on the back .

give yourself a pat on the back .

- The pills help .

- 4 , The turret .

. . . the turret is 144mm diameter , which is pretty good scale wise , so nothing drastic is required there .( I made the ring a millimeter undersisze so that a dark line showed all around the edge as a visual guide when sanding back later )

. . . the turret is 144mm diameter , which is pretty good scale wise , so nothing drastic is required there .( I made the ring a millimeter undersisze so that a dark line showed all around the edge as a visual guide when sanding back later )

- . . . . Simples

- 'coz the gun ring in the hulls next . . .

to the bouncy room ! Yay !

-

tankman

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Slow down PLEASE my brain is hurting lol. Nice job on the turret though, it's one of those job's I need to do when I get round to doing my old H/L. Those bloody Asaitam steel wheels are pretty crap from the off though. Thanks for sharing

Alan

Alan

- blimp

- Sergeant

- Posts: 745

- Joined: Sat Dec 11, 2010 12:29 am

- Location: Watford , NW Londonistan . U.K.

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Slow down ? trust me , continents move faster

- Pt 4b . the hull ring .

- . . . With the turret now sorted out , the next logical thing to do is the hull deck , i did the usual plastic disc trick (tacked in place) don't forget to faintly mark a line along the centre of the hull roof - THIS IS IMPORTANT. The turret needs to be 72mm forward of the engine hatch line , plus a smidgin for clearence - i added another 1mm - too much as i found out , the CORRECT distance is 13mm back from where H/L has it .

- . . . . . back soon with all the gory details . . . * Her ladyship wants to drag me off somewhere , no doubt it'll involve my wallet .

to the bouncy room ! Yay !

- blimp

- Sergeant

- Posts: 745

- Joined: Sat Dec 11, 2010 12:29 am

- Location: Watford , NW Londonistan . U.K.

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

. . . . Allrighty then , where was i ? ah yes , my little mod . . .

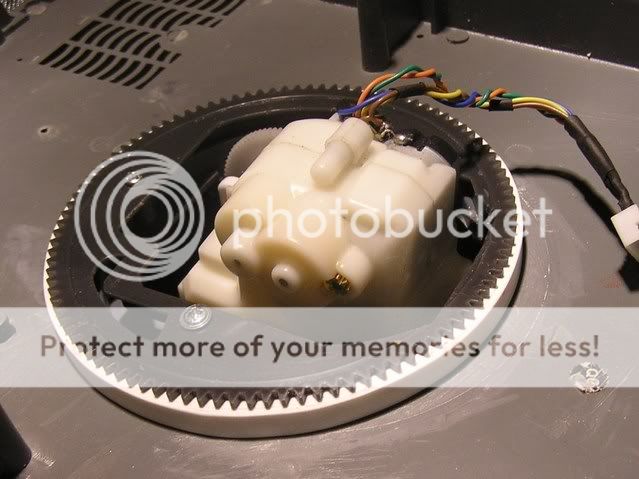

As most Tiggy owners know , the fit of the turret is less than erm , perfect shall we say . . . the hole in the hull is not one of H/L's best moulded parts , oversized , tapered and not actually round . combined with the strange turret gear 'step' and a deck that's as solid as a trampoline and the turret happily wobbles like a jelly . and just so happens to be 96mm o/d x 92.3mm i/d (a slip on fit for the gear ring) x 9mm deep ( the distance from the turret floor to the top of the gear) . . .

and just so happens to be 96mm o/d x 92.3mm i/d (a slip on fit for the gear ring) x 9mm deep ( the distance from the turret floor to the top of the gear) . . .

- you didn't notice that other mod inside the turret did you - right ?

- you didn't notice that other mod inside the turret did you - right ?

As most Tiggy owners know , the fit of the turret is less than erm , perfect shall we say . . . the hole in the hull is not one of H/L's best moulded parts , oversized , tapered and not actually round . combined with the strange turret gear 'step' and a deck that's as solid as a trampoline and the turret happily wobbles like a jelly .

- To fix it i carried out the previous steps , but enlarged the hole to 96mm diameter . then removed the top and bottom raised portions entirely .

- . . it still requires a polish and a section removing to clear the repositioned turret motor and i've just bought some brass section tube , to be extra cross beams to stiffen the deck as well . A .6mm / .025" disc turret gap spacer , or I might even make a roller bearing for it , i'll see how it behaves first .

- Nighty night .

to the bouncy room ! Yay !

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Beautiful work.

best wishes,

jeff

best wishes,

jeff

- majordisastor

- Lance Corporal

- Posts: 208

- Joined: Fri Apr 23, 2010 5:24 pm

- Location: Llantrisant, South Wales

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

Good conversion that will sort out any short comings with the turret rotatio for sure!!

If you think the Heng Long deck is a litlle floppy - try a Tamiya deck - I have eaten Lasagne sheets with greater structural integrity ...................

Andy

If you think the Heng Long deck is a litlle floppy - try a Tamiya deck - I have eaten Lasagne sheets with greater structural integrity ...................

Andy

It always gets darkest before it goes completley black......

- blimp

- Sergeant

- Posts: 745

- Joined: Sat Dec 11, 2010 12:29 am

- Location: Watford , NW Londonistan . U.K.

Re: gawd , another Tiger 1 (late) w.i.p. yawn . . .

I have the day off Yay! so heres a quick update -  the gear teeth just clear it - i could have put the beam in at a slight angle but it looks odd like that , anyway it does go .

the gear teeth just clear it - i could have put the beam in at a slight angle but it looks odd like that , anyway it does go .

- So on with erm , lessee , Pt 4c ?

- - The black marks on the ring are 'witnesses' of some little tight spots , a gentle sanding and polish will cure that . I won't be using any grease here , it attracts dirt , a rub with a bit of candle/bees wax will act as lube , it'll stop the ring oxidizing as well . . . clever eh ?

to the bouncy room ! Yay !