- Cowl supports

Putting a decent curve into the Cowling shroud is ... (as I recall from my previous efforts on the Cromwell build)... something of a nightmare. You can try heat and hot water, to fashion curved panels; but they don't seem to work very well. Using a heat gun can condemn the newly shrivelled up, curled, or permanently twisted styrene sheet to the rubbish bin, with only a tiny tad too much heat.

I learned this the hard way.

One method I tried of 'softening up' the reluctant styrene panel, was to score lots of lines on the inside of the panel, using a Tamiya scriber (one of my favourite tools). Here:

- Scoring styrene sheet to form a curve

(Do click on all these images to ENLARGE them, by the way.)

Well, while this helped to weaken the panel, it also produced a very complex polygonal on the outside (like the old threepenny bit). This simply wouldn't cut the mustard, and so I abandoned that idea.

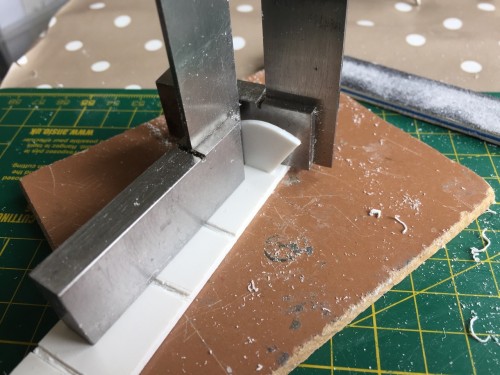

Instead, what I did, first of all, was to bond all of the curved segments to a 3mm piece of styrene- having first cut slots out, to embed them in:

- Fitting curved supports to base

Then I bonded the front edge of the shroud, allowing it to cure for quite a while.

- Attaching shroud

"Get your facts first, and then you can distort them as much as you please"- Mark Twain.