started with the commanders coupola, as many will know, it needs some detailing as well as turning to the correct position on the top of the turret, so that was the first thing i set about removing.

luckily the glue monkey had not been taking happy pills when he glued mine on and with a bit of careful scoring with a sharp knife it came off.

leaning and stripping was shall we say a little more tedious, obviously the glue monkey had had a tea break and popped a happy pill when this was put together in the factory, and getting the hinge apart from the main cupola proved more of a challenge, but not dismayed I soldiered on and eventually managed to get the whole thing in bits.

one of the first problems I wanted to solve was the closing of the hatch, as I don't know about the rest of you's experiences but mine always sat a little open, (not good), so I set about cleaning the mould lines and sanding with some wet and dry, once happy with the sanding/cleaning I dry fitted the whole thing back together.

happy now that the hatch closed correctly I started on the detailing of the inner hatch, thatnks to you guys I got some pics of the locking mechanisim and after a rummage through one of my many bits boxes I found some bits that would help make the locks, that and some piano wire.

I know the results are not fantastic but I think they do the job, as I didn't fancy spending a small fortune on the white metal ones that probably only cost a couple of quid in metal to make.

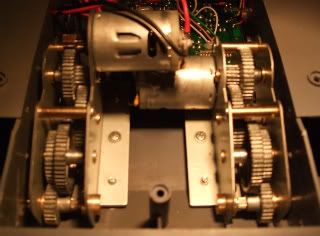

The Barrel extension and changing round of the gun mantel were my next stage of the project, I stripped the gun and cut the mid section completely out of the barrel, using a 48th scale barrel I measured up scaled to 1-1 then down scaled again to 1/16 with this measurement I cut the brass tube and plastic tube packing to length, the inner airsoft barrel was also renewed and correct length to fit inside the main barrel, I then drilled the two holes in the airsoft barrel that were needed to release/draw air and fitted the whole lot back together.

turning the mantlet was a pretty easy job, with a few hole to drill and a small amount of cutting with a modelling grinder attachmentto take down the old screw fitting lugs.