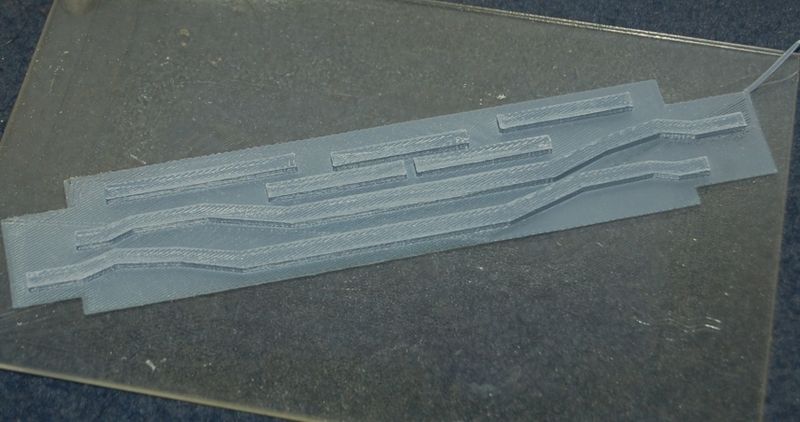

After a lot of trial and error trying all sorts of bed adhesion solutions, I found that a Pritt glue stick was the best by a country mile. Just scribble it onto the glass, and print. When finished, run it under a tap (it's water solubale) and wipe with a sponge, hey presto one pristine print bed again. Slot it back in, push a button on the LCD screen and away it goes again.

The one thing that will lift a print, and I was amazed at how susceptible it made the adhesion, was leaving a patio door open. Just that tiny bit of air circulation would do it, so all doors and windows are now closed whenever I print anything. I can print hollow objects 100mm long and 200mm high without any support material, and nothing moves....except the contents of my wallet when I have to order more filament.

Now off to find the 3D software, I would like to have a play with it.

RobG