M7 Priest scratchbuild

- AlwynTurner

- 2nd Lieutenant

- Posts: 2656

- Joined: Thu Oct 23, 2014 10:47 am

- Location: Chapel-en-le-Frith, Derbyshire

Re: M7 Priest scratchbuild

I've wired up my modded servos but they are way too fast  , can I slow them down by putting a resistor into the circuit, basically reducing the voltage (is that right?). My knowledge of electronics is miniscule so any help would be most appreciated. Thanks Alwyn

, can I slow them down by putting a resistor into the circuit, basically reducing the voltage (is that right?). My knowledge of electronics is miniscule so any help would be most appreciated. Thanks Alwyn

YOU'RE NEVER TOO OLD TO HAVE A HAPPY CHILDHOOD!

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

-

mcevoyi

- 2nd Lieutenant

- Posts: 2297

- Joined: Fri Sep 26, 2008 11:24 pm

- Location: Now Living in Cyprus .... Modellers desart ...

Re: M7 Priest scratchbuild

I am really enjoying watching the build

..there a lot of inspection and ideas here

Seriously top notch build

..there a lot of inspection and ideas here

Seriously top notch build

- AlwynTurner

- 2nd Lieutenant

- Posts: 2656

- Joined: Thu Oct 23, 2014 10:47 am

- Location: Chapel-en-le-Frith, Derbyshire

Re: M7 Priest scratchbuild

Hmmm..., figured out the problem, the micro servos were intended for drone copters, and work on 3.7v +/-, so they are being fed vastly more volts and therefore whizzing round much too quickly. After reading up and researching it seems I can reduce the voltage by using a 22 ohm to 100 ohm resister in series with the motor, so now waiting for a pack of resistors to arrive. It will cut the torque available but that shouldn't be an issue as the elevation is working on a fairly light and counterbalanced barrel, and I am getting so much torque on the slew motor it is breaking the joint attaching the servo to the body, so less torque would be a plus!  Alwyn

Alwyn

YOU'RE NEVER TOO OLD TO HAVE A HAPPY CHILDHOOD!

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

- wibblywobbly

- Major

- Posts: 6396

- Joined: Fri Oct 17, 2008 9:30 am

- Location: South Wales Valley

- Contact:

Re: M7 Priest scratchbuild

One way around the servo speed would be to put an arm in the mechanism somewhere, so that you had a long section going to a pivot, and then a short section from the pivot to the part that you wanted to move. That way the long arm creates a lever that gives more leverage/torque, and the long travel at that end results in a short travel at the other. Depends how much space you have I guess.

On that subject I was looking at an old HL recoil unit the other day, and it dawned on me that they have a rack and pinion inside. Theoretically the return springs and microswitches could be removed, plug it into the turret rotation socket, and it becomes a linear actuator, could be used to move anything backwards and forwards under joystick control? Probably a bit bulky, but a cheap solution for anyone that wants a device like that.

RobG

On that subject I was looking at an old HL recoil unit the other day, and it dawned on me that they have a rack and pinion inside. Theoretically the return springs and microswitches could be removed, plug it into the turret rotation socket, and it becomes a linear actuator, could be used to move anything backwards and forwards under joystick control? Probably a bit bulky, but a cheap solution for anyone that wants a device like that.

RobG

Tiger 1 Late

Panther G

King Tiger

M36 B1

Panther G

King Tiger

M36 B1

- AlwynTurner

- 2nd Lieutenant

- Posts: 2656

- Joined: Thu Oct 23, 2014 10:47 am

- Location: Chapel-en-le-Frith, Derbyshire

Re: M7 Priest scratchbuild

Success!!!!

Got the pack of resistors and after a false start with 100 ohm resistor, put a 47 ohm resistor in series with the motor and hey presto, it worked like a dream! The speed is now correct and the torque is reduced so it's not pulling the mechanism apart, so for anyone else trying this approach, with micro servo motors (i.e. the mini drone kind) you will need a 47 ohm resistor in series to get a sensible speed response. Now I can finish the wiring loom including the lights and progress the build!

Got the pack of resistors and after a false start with 100 ohm resistor, put a 47 ohm resistor in series with the motor and hey presto, it worked like a dream! The speed is now correct and the torque is reduced so it's not pulling the mechanism apart, so for anyone else trying this approach, with micro servo motors (i.e. the mini drone kind) you will need a 47 ohm resistor in series to get a sensible speed response. Now I can finish the wiring loom including the lights and progress the build!

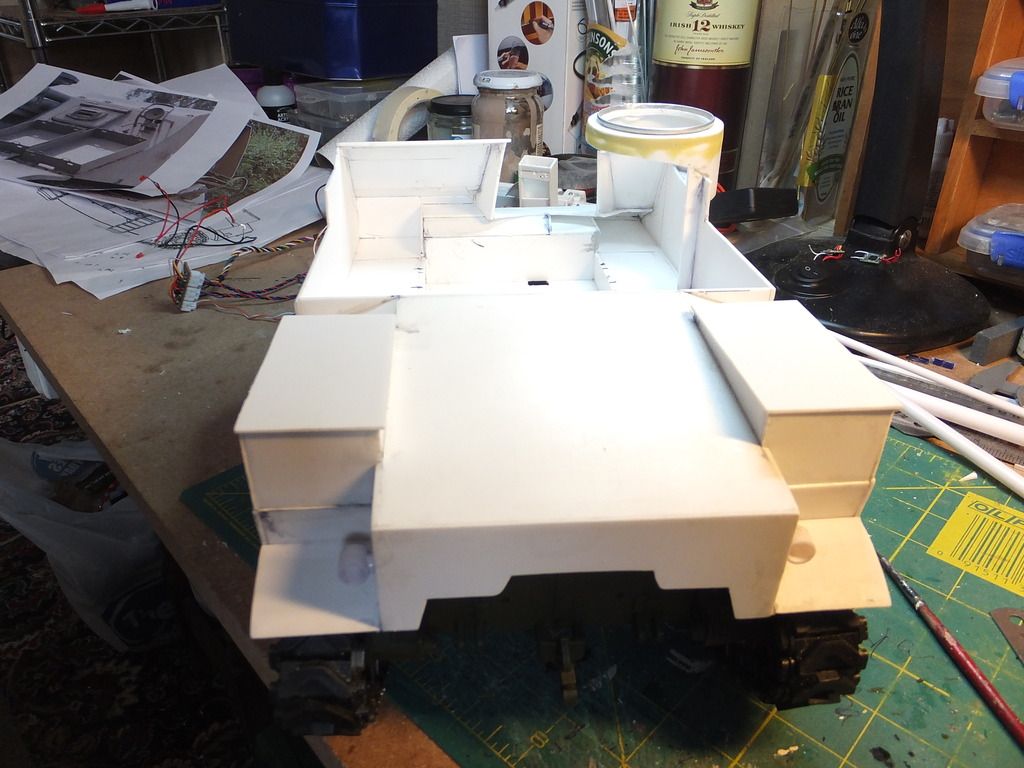

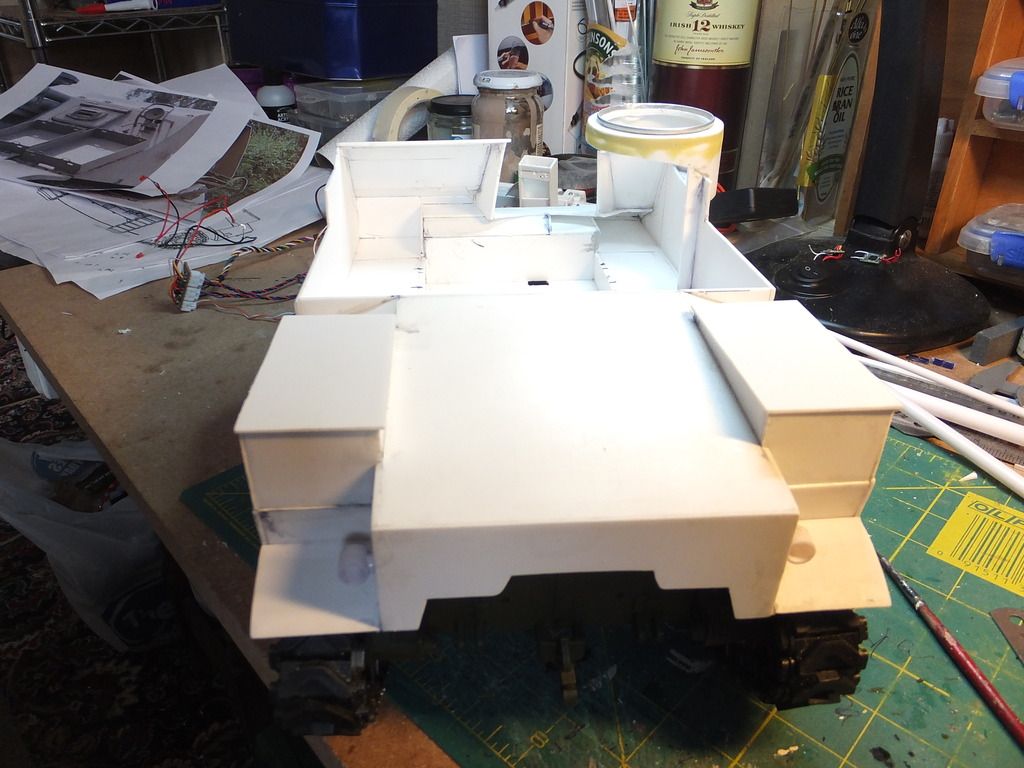

Whilst waiting for the parts I put the front and back mudguards on, tidied up the inside front of the upper hull so the gearboxes are hidden, and put the rear lights on.

Next up is the driver viewing hatch and the headlights. I'll probably take it to the MAD meet on Sunday and give it a test run.

Alwyn

Alwyn

Whilst waiting for the parts I put the front and back mudguards on, tidied up the inside front of the upper hull so the gearboxes are hidden, and put the rear lights on.

Next up is the driver viewing hatch and the headlights. I'll probably take it to the MAD meet on Sunday and give it a test run.

YOU'RE NEVER TOO OLD TO HAVE A HAPPY CHILDHOOD!

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

- wibblywobbly

- Major

- Posts: 6396

- Joined: Fri Oct 17, 2008 9:30 am

- Location: South Wales Valley

- Contact:

Re: M7 Priest scratchbuild

Glad you got the problem sorted, it's coming along very nicely, can't wait to see it completed.

Tiger 1 Late

Panther G

King Tiger

M36 B1

Panther G

King Tiger

M36 B1

-

edpanzer

- Warrant Officer 2nd Class

- Posts: 1317

- Joined: Tue Jan 06, 2015 9:59 pm

- Location: Peterborough Cambridgeshire UK

Re: M7 Priest scratchbuild

Saw this and thought of you they even have a video showing it workingAlwynTurner wrote:Hmmm..., figured out the problem, the micro servos were intended for drone copters, and work on 3.7v +/-, so they are being fed vastly more volts and therefore whizzing round much too quickly. After reading up and researching it seems I can reduce the voltage by using a 22 ohm to 100 ohm resister in series with the motor, so now waiting for a pack of resistors to arrive. It will cut the torque available but that shouldn't be an issue as the elevation is working on a fairly light and counterbalanced barrel, and I am getting so much torque on the slew motor it is breaking the joint attaching the servo to the body, so less torque would be a plus!Alwyn

http://rctanksaustralia.com/shop/index. ... cts_id=194

Taigen Tiger 1 full option rctank.de special edition airbrush paint IR equipped

Type 90 1/24

WSN T34

Heng long leopard 2a6

Heng long panzer 4 platinum

Heng long sherman

Grantham Light Armoured Division RCTC

Type 90 1/24

WSN T34

Heng long leopard 2a6

Heng long panzer 4 platinum

Heng long sherman

Grantham Light Armoured Division RCTC

- AlwynTurner

- 2nd Lieutenant

- Posts: 2656

- Joined: Thu Oct 23, 2014 10:47 am

- Location: Chapel-en-le-Frith, Derbyshire

Re: M7 Priest scratchbuild

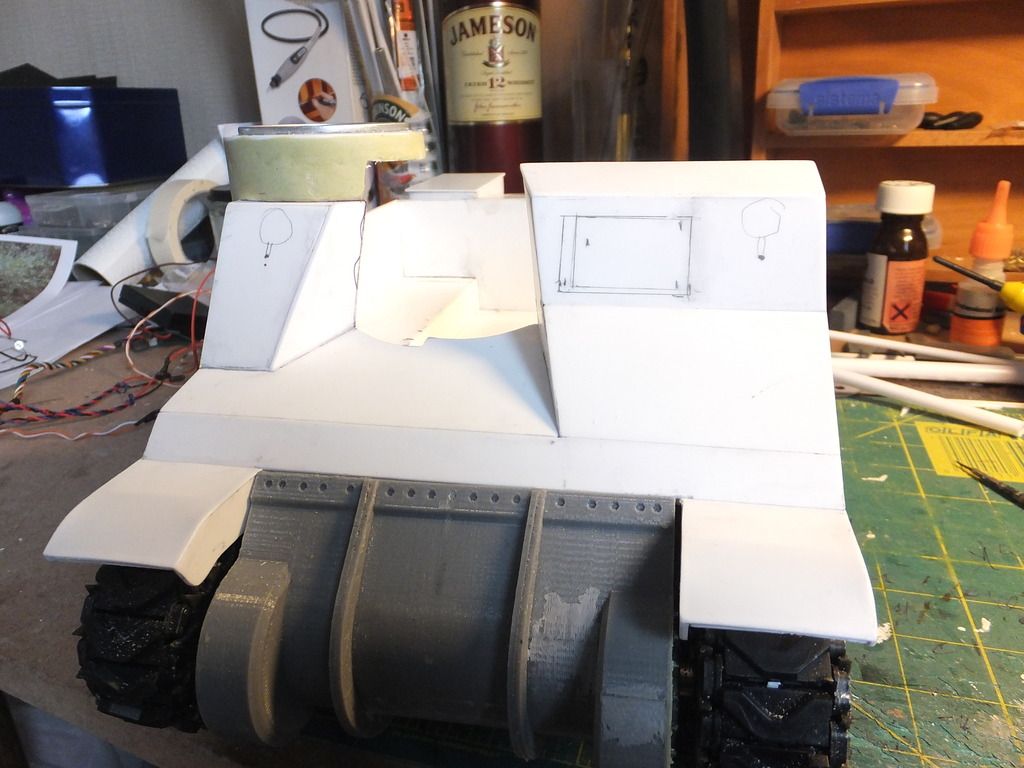

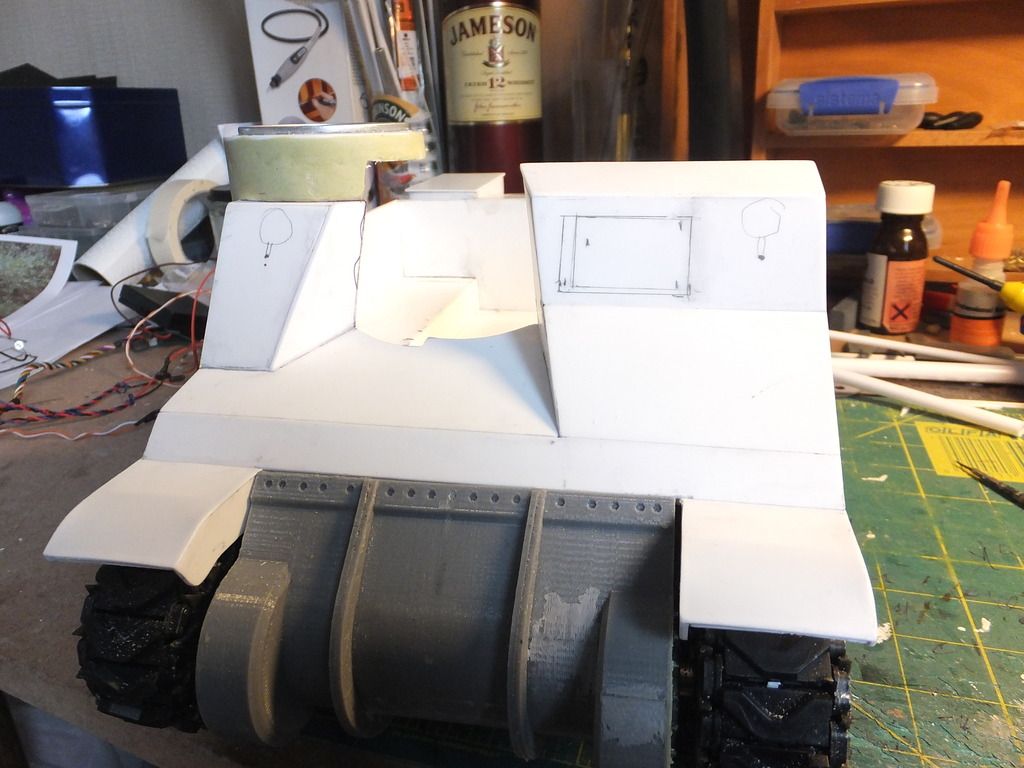

Drivers hatch and front lights done, hull welds done on the front but still plenty to do on the back. I think the welds look a bit heavy, but some of the photos of actual M7s show fairly heavy welds too so I'll leave them for now, I may revisit them later.

I'm waiting for white leds to arrive and then I can get the lights wired up. Lots of work to do on the gun but it's coming along. Alwyn

Alwyn

I'm waiting for white leds to arrive and then I can get the lights wired up. Lots of work to do on the gun but it's coming along.

YOU'RE NEVER TOO OLD TO HAVE A HAPPY CHILDHOOD!

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

-

edpanzer

- Warrant Officer 2nd Class

- Posts: 1317

- Joined: Tue Jan 06, 2015 9:59 pm

- Location: Peterborough Cambridgeshire UK

Re: M7 Priest scratchbuild

Looking great!!!!!!!!

Taigen Tiger 1 full option rctank.de special edition airbrush paint IR equipped

Type 90 1/24

WSN T34

Heng long leopard 2a6

Heng long panzer 4 platinum

Heng long sherman

Grantham Light Armoured Division RCTC

Type 90 1/24

WSN T34

Heng long leopard 2a6

Heng long panzer 4 platinum

Heng long sherman

Grantham Light Armoured Division RCTC

- AlwynTurner

- 2nd Lieutenant

- Posts: 2656

- Joined: Thu Oct 23, 2014 10:47 am

- Location: Chapel-en-le-Frith, Derbyshire

Re: M7 Priest scratchbuild progress

Well finished fixing the motorhome and clearing up the house after the Italy trip and I can now get down to the important work on the Priest.

Finished wiring the front and rear lights but still can't find any white lcds that work at 1.3v, so had to settle for yellow. The spare track racks are on and the first of the fuel filler caps.

I'm really fed up as I tried to fire up the rx18 and for some reason it's not starting up, so now I have to try and fix that. It was all working fine before I left for hols so I really am confused, the lights flash but no action on the start button. Tried a different tx, a different rx, now I'll have to try changing the rx18!

Alwyn

Alwyn

Finished wiring the front and rear lights but still can't find any white lcds that work at 1.3v, so had to settle for yellow. The spare track racks are on and the first of the fuel filler caps.

I'm really fed up as I tried to fire up the rx18 and for some reason it's not starting up, so now I have to try and fix that. It was all working fine before I left for hols so I really am confused, the lights flash but no action on the start button. Tried a different tx, a different rx, now I'll have to try changing the rx18!

YOU'RE NEVER TOO OLD TO HAVE A HAPPY CHILDHOOD!

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild

Saladin scratchbuild, Matilda scratchbuild, Churchill scratchbuild, Crusader scratchbuild, M10 Achiĺles scratchbuild, Universal Carrier scratchbuild