I have started to build some time ago, but now would like to present here the building report.

It has always been my desire to provide a Tamiya Tiger I with some tags on the chains.

Gradually, I have vers. Concerned components and had the good fortune in the summer

still a virgin kit of the object model to bekommen.Wie many are there know many of the necessary parts included for an early execution.

As my english is not very good, I will show you many pictures of the remodeling and construction show.

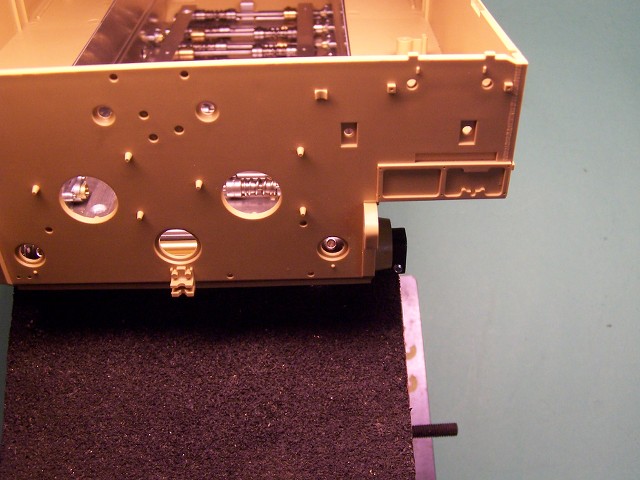

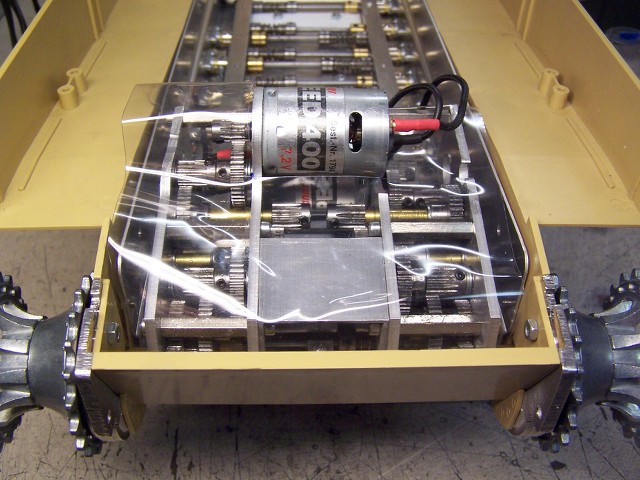

I wanted to replace the entire suspension and installing quite different as you know from Tamiya .

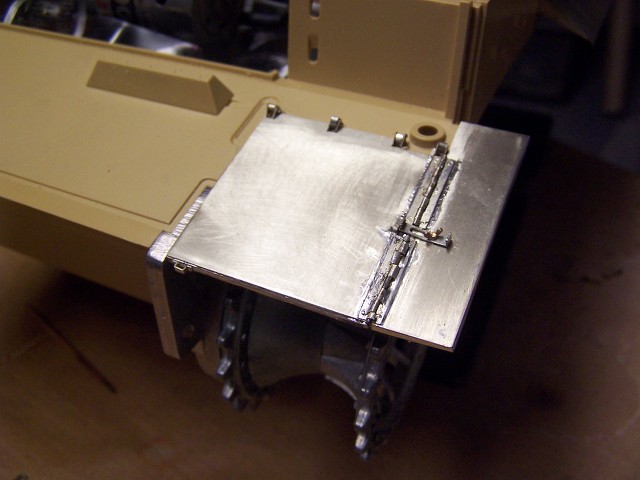

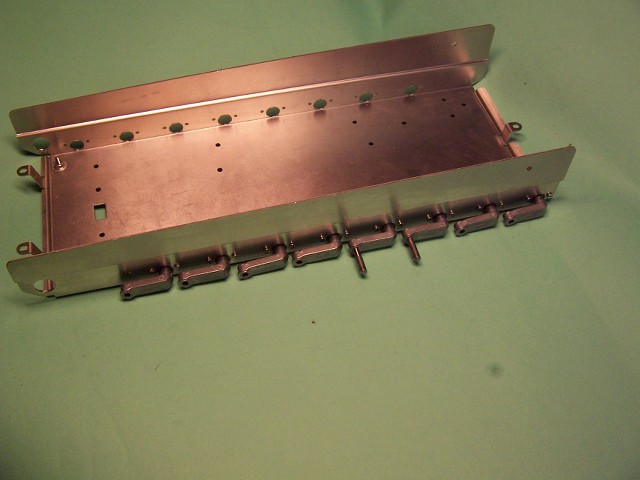

The first change to the lower hull rebuild the holder

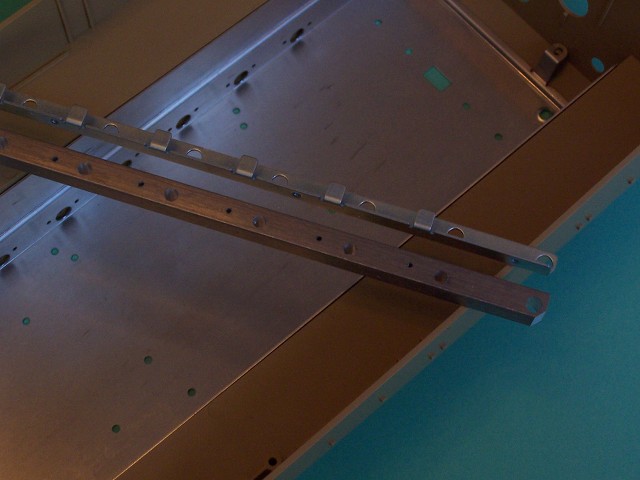

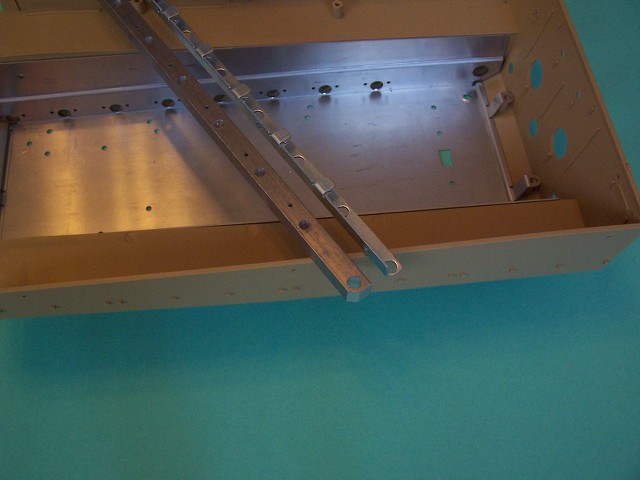

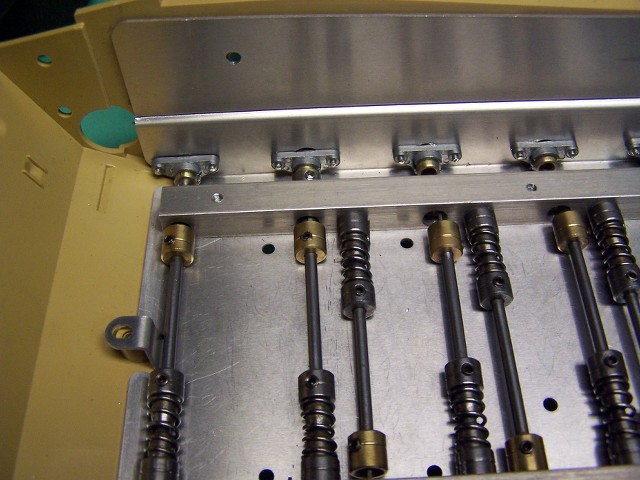

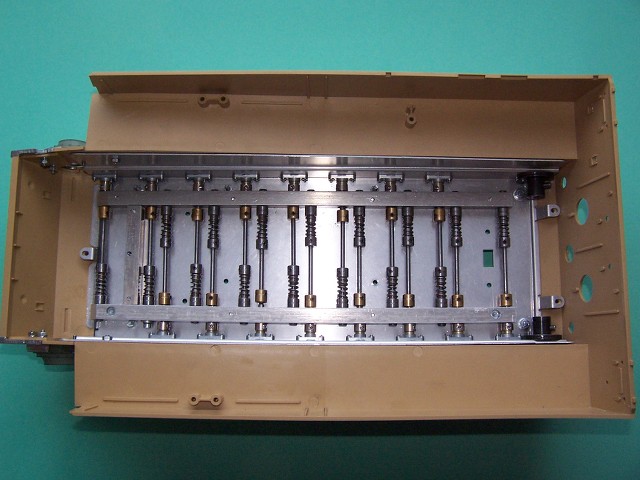

Because I want to install a real working suspension, I copy the dimensions of the Tamiya part on 10x10 aluminum square. In this camp, the swing arms are guided play.

To drill much as you can see, but the result zählt.Diese type of thrust bearing I have ever made ??for a friend, so basically nothing new.

Again, I'm working on the premise that it is intended that all can be removed again and it should find use standard parts which can also be once again make later.

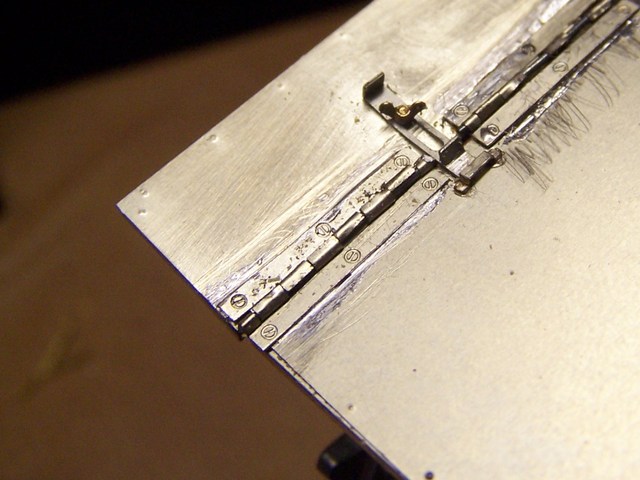

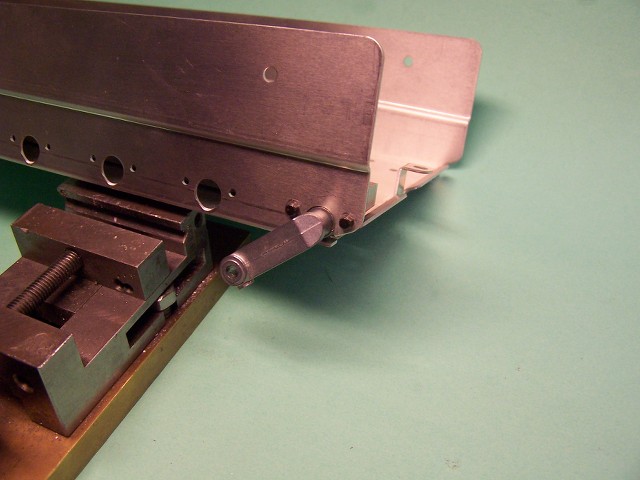

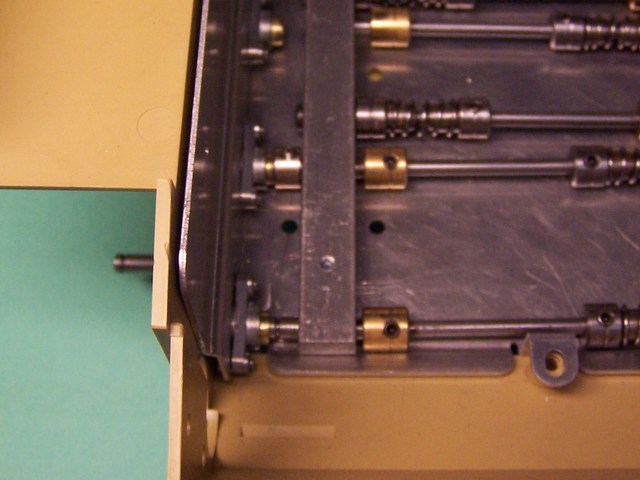

The rocker arms themselves must werden.Dazu accordingly rebuilt I have first sawed-drilled and used a steel axle.

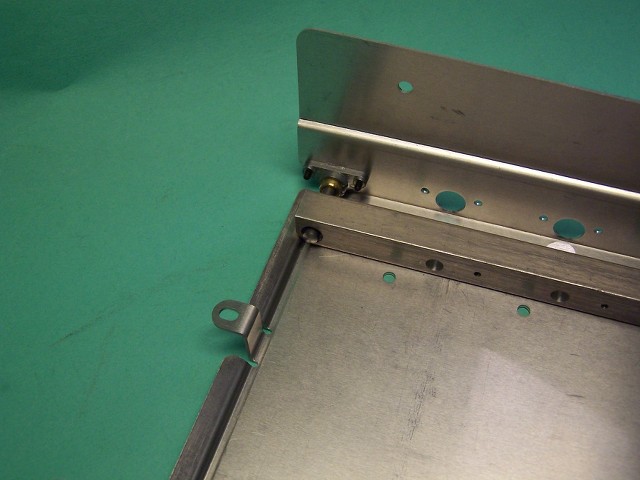

As already mentioned, I turn to the storage of the arms and the rocker arms themselves.

In order to process the camp, I got myself a workpiece Done In what I can tighten the bearings

]

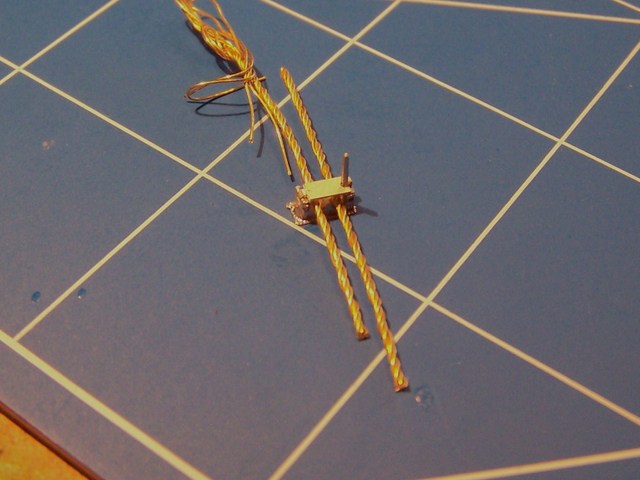

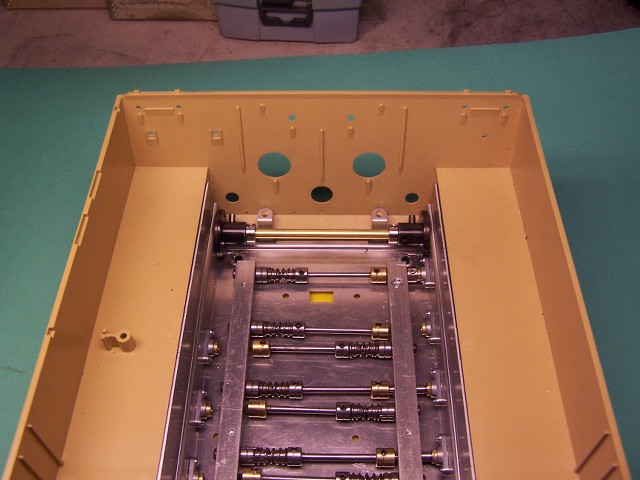

And so it looks to the sample also assembled, all I'm going to repeat it 15 times and then goes further.

Now we continue with installation of manufactured parts......

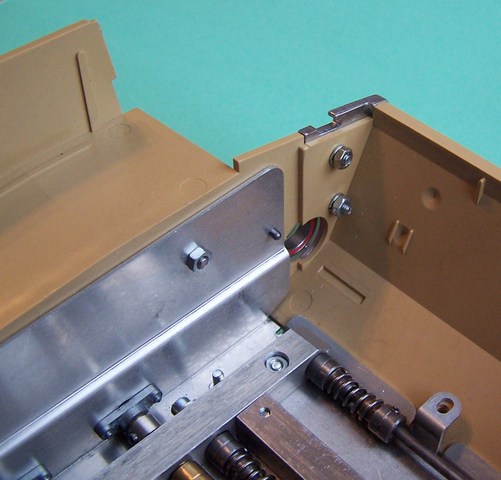

then made ??also a chain tensioner which you can set by maintenance hatches

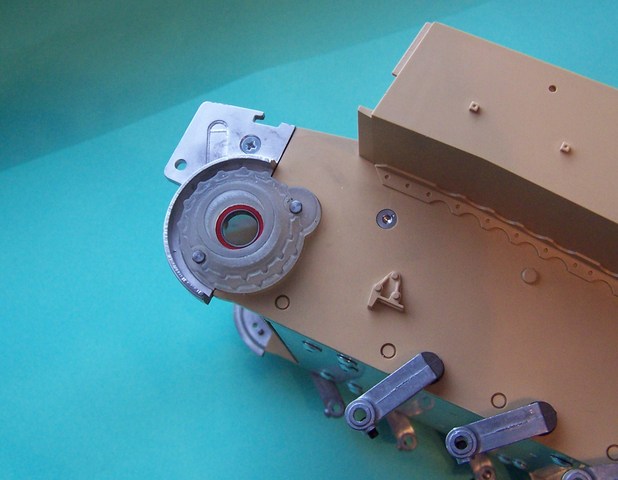

the wheels I have fitted with ball bearings.......

Now the suspension is completed and installed.

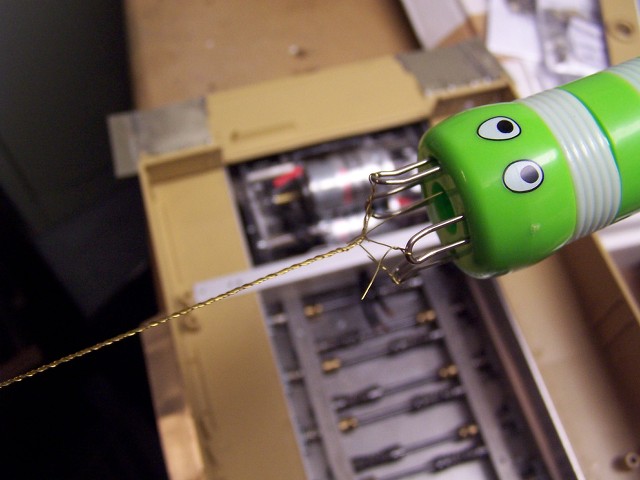

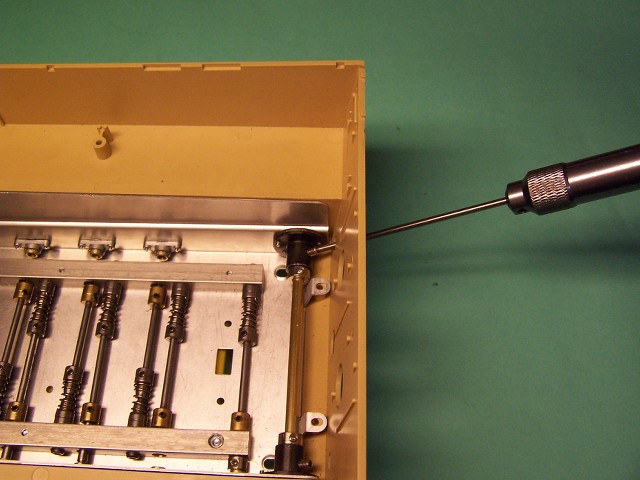

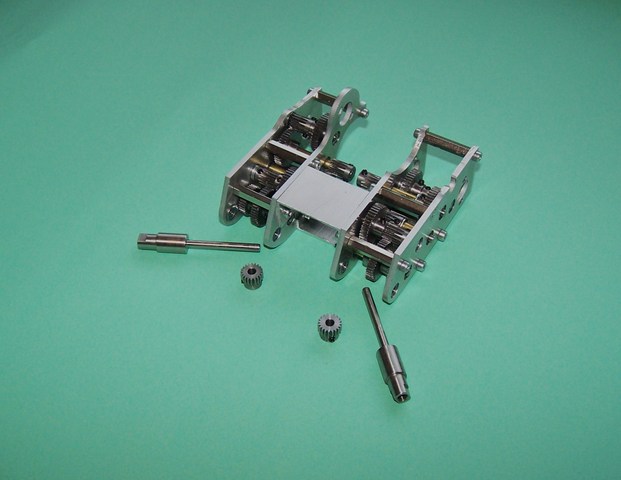

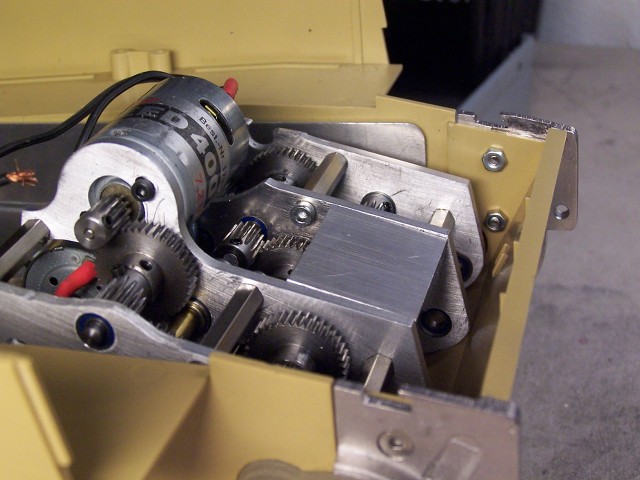

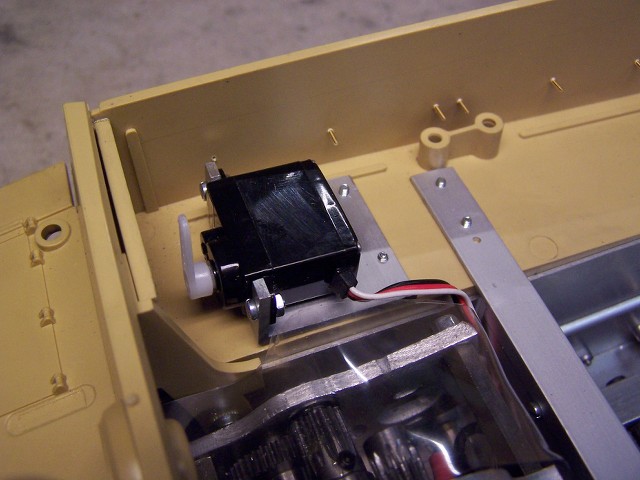

Time to install the gearbox.

I can buy a used Marcel-Rientjes last year

. It was not in good condition, so I have renewed all axes and of course a new output shaft inserted from my shop.

The two gearbox halves, I have bolted to box sections, so I have always clearly aligned gear,

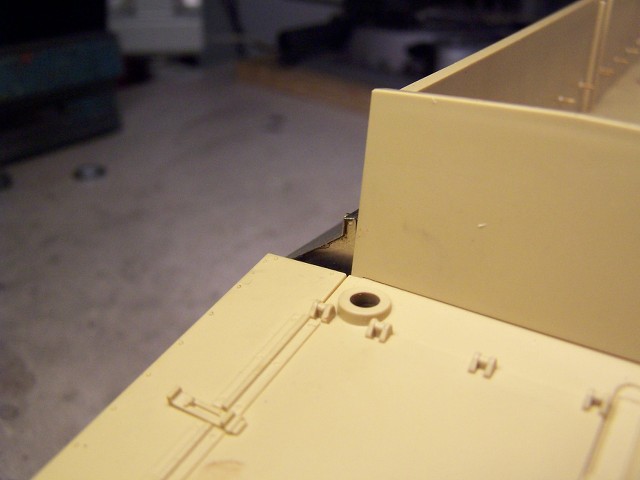

the front pieces are build by Profesionalkits, currently sold Chris these parts.

Then I have installed by Marcel Rientjes the outriggers with ball bearings.

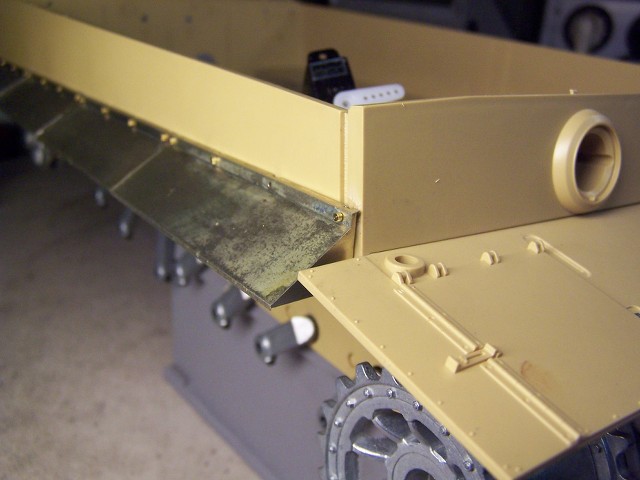

as a splash guard I have brought material of packaging with a hair dryer in the form.

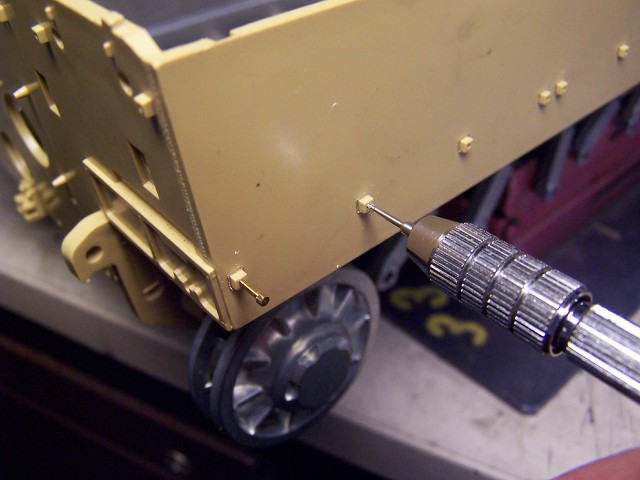

I begin with the construction of the Aber- etch parts on the Lowerhull........

the work actually went very fast, the fenders will probably need a bit longer

In the tub I have stably incorporated a servo in the meantime, and a further strengthening of aluminum.

Provided with threads and screwed from below.....

To be continued......

Regards,Guido