as some may know i just got my first rc tank , after reading through some of the threads on these and other forums i have become aware of a few of the issues with these toys .

i am fairly busy but will keep this thread updated as and when i do a few of the mods ,

taigen lower hull is on the way from forgebear ,

400 size high torque motors as recommended elsewhere on this forum are on the way ,

10 tooth pinion and 1/8- 3/32 bore brass tube to act as motor shaft spacers will be ordered soon ,

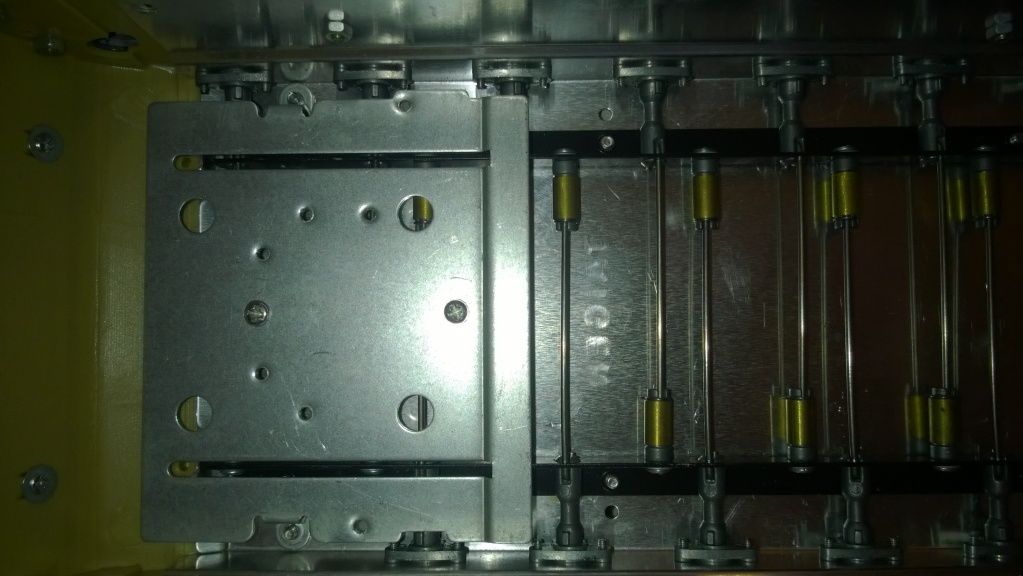

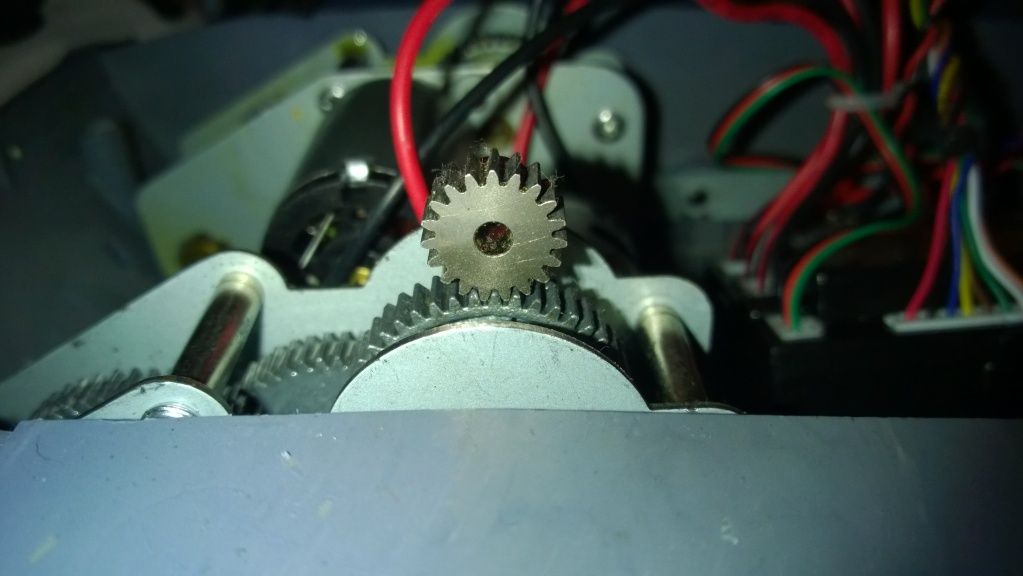

i have searched the forum to find out what pitch the gears are , 48 pitch, 46 pitch , module 0.5 , i dont know about all versions but my silver pot metal heng long boxes are module 0.6

,

, the external detail will come soon , i will admit that the whole detail modelling aspect is completely new to me so you will most likely get a good laugh at my efforts

more soon