Page 1 of 5

My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 1:04 am

by sunray

Hi. I brought my Tiger second hand off ebay. I had earlier brought my young son a brand new Tiger for his birthday and I didn't think he would like the idea of me taking it to bits. My Tiger cost about £30 but wasn't in working order so I thought hear we go. After reading the forums to find out how to strip the tank down I managed to get the tank working (all it was a loose wire). As it was an early Heng Long Tiger I had to change around the gun mantle, the pistol port and the commander hatch on the turret. I also added smoke dischargers, a barrel extension, an escape hatch and a few mods to the turret itself with a heat gun. I had to get a new escape hatch as I melted the original one by mistake.

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 1:27 am

by sunray

The next thing I did was remove the tools from the main body, open up the driver slit, open the drivers and machine gunners hatches, add new lights and use the heat gun again. I opened up the drivers hatch, etc because I wanted to move the on off switch from the bottom of the tank and add a volume switch.

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 1:34 am

by Reaper332

Looks great so far Sunray, looking forward to seeing it finished.

Cheers Ken

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 2:24 am

by sunray

Now it was the turn of the main hull. I decided to get metal tracks, metal sprocket and idler wheels, track tensioner, metal suspension arms, metal reinforcing bars, metal gears and new RX18 Control Box. Most of the stuff was straight forward to fit except for the track tensioner, suspension arms and the RX18.

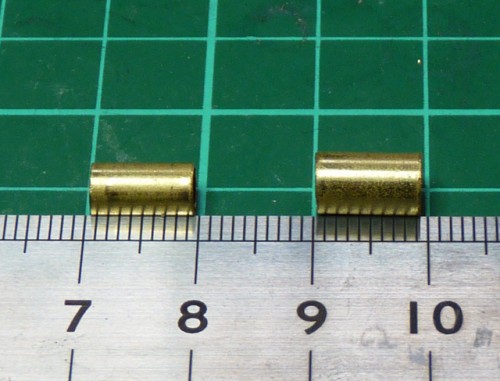

The track tensioner I got was an early version which I found was too loose a fit some I decided to modify it a bit. This is what I did. I went to my local DIY store and bought brass tubing of different diameters to put over the idler shaft to increase the diameter but not restrict movement on the shaft.

- Brass tubing

- Brass tubing cut to approx 9mm

The tubing is placed on the tensioner shaft.

- The smaller diameter first.

- Then the larger diameter tubing.

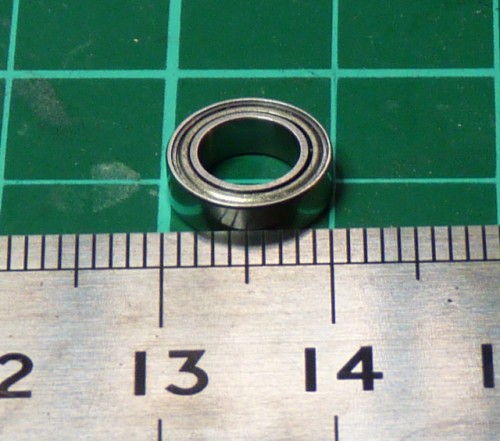

I used a 10mm bearing which I got from my local model shop for about £1.50 each.

- 10mm bearing

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 2:26 am

by sunray

Thanks for that Ken.

Ian

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 3:43 am

by sunray

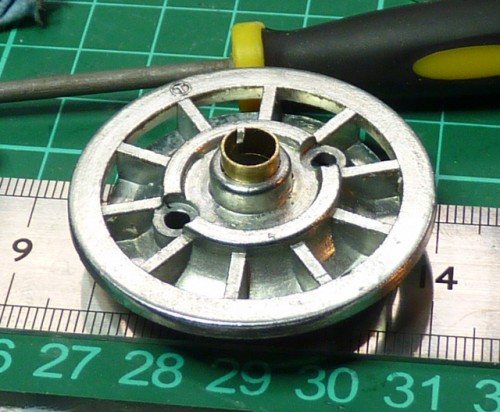

Because the diameter of the bearing was 10mm I had to widen the hole of the Idler wheel as it was 9.5mm. This was done with my Dremel.

- I used a stone instead of a drill bit as the Idler wheel metal is a bit soft.

- The Bearing is fitted to the Idler wheel.

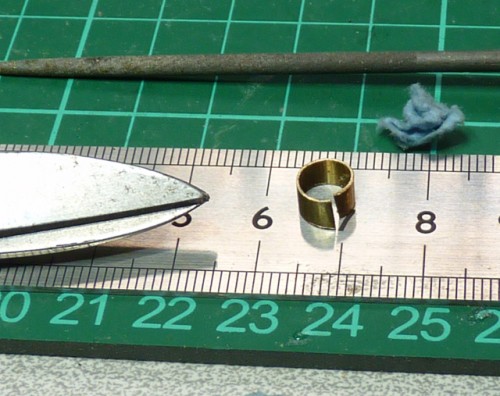

To ensure a closer fit for the rear half of the Idler wheel around the shaft I added a brass collet which is quite easy even for me. I cut about a 5mm piece of the brass tubing cut into it with tin snipes.

- Brass collet.

The collet is then placed in the idler wheel.

- You might have to cut some more with the snipes for it to fit.

Now push the collet in so it is flush with the Idler wheel.

- If not just pop it out and file down.

On the shaft itself I added a few washes and covered it in grease.

I placed the wheel on the shaft then added one or two more washes.

I tighten then together using a nut, just enough to ensure the wheel was free running. I then added a nut filed down to fit and super glued to the end of the shaft. I didn't use lock nuts as I didn't have the right size.

I then fitted the front half of the Idler wheel. It now spins freely on the shaft with little or no play.

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 4:58 pm

by sunray

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 6:01 pm

by sunray

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 6:24 pm

by tisaksen

I am so impressed with this build. Awesome

Re: My First Tiger and Still Upgrading

Posted: Mon Feb 27, 2012 7:33 pm

by sunray