Page 1 of 1

Repositioning the 3 support rollers on each side

Posted: Sat Mar 01, 2025 1:17 pm

by Rob59

G'day guys.

As I mentioned already in another thread on here, I bought me a new StuG III from Aliexpress for little money.

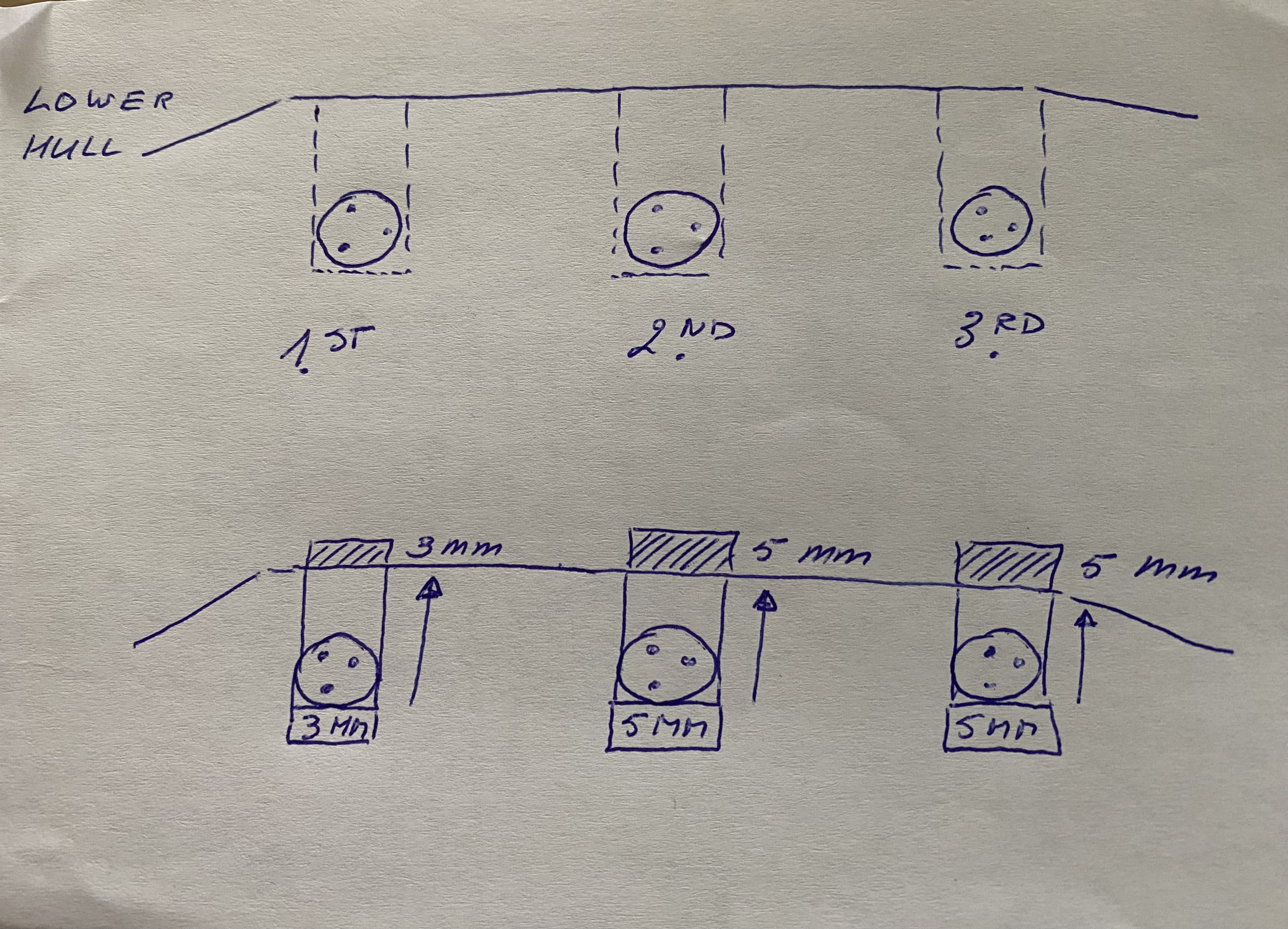

Now I want to reposition the support rollers, in a higher and more correct position.

The front one should be raised 3mm and the other two 5mm.

The plan was/is, to start sawing straight down from the top of the lower hull downwards till the bottom of the roller support.

Than I will cut the horizontal line between both sawn cuts with a sharp knife, so I can take the complete support roller out of the hull.

Next I will fill up the first one with 3mm poly, both others with 5mm, so they get in the wanted position.

If the position is correct, I will take off the part above the supports so they will be in line with the top of the upper hull again.

I made a little sketch to explain what I had in mind.

Of course there will be some supports made out of poly which I will glue inside the hull, behind the repositioned rollers!

If any of you guys has a better idea, I am open for suggestions!

Thanks,

Rob

- IMG_3481.jpeg (2.76 MiB) Viewed 4562 times

Re: Repositioning the 3 support rollers on each side

Posted: Mon Mar 03, 2025 8:36 pm

by Herr Dr. Professor

Rob59: here's HDP's dumb idea #2348: if the support roller assemblies are symmetrical side to side and up and down, perhaps you could

1. cut out the rollers just as you describe,

2. turn upside down each rectangle of plastic with its affixed support roller,

3. cut the rectangle of plastic so there is the 3 or 5 mm,+

4. insert and glue in the (now "upside down") rectangle of plastic with its affixed support roller assembly

5. fill in the upper gap with the needed amount of plastic.

So WHY do the modification this way?

Well, I am guessing that potential downward stress on the modified support roller assembly would be better handled with just one horizontal joining, not two.

Re: Repositioning the 3 support rollers on each side

Posted: Mon Mar 03, 2025 10:27 pm

by Jofaur86

Another idea, possible, but without a photo of the construction site? Not easy to explain..

I suppose that these rollers are concentric? then? would it not be possible to cut all around, using a small 1 mm drill in a mini drill, and then actually cut between the holes with an Xacto, redo a hole of the same diameter as the cut part after deburring, put in place a piece of pasticard, which will cover the two holes? the old one (which can be filled after cutting a circle, and glued, finish with a good putty, any imperfections. A lot of surgical work? but does not weaken the hull. and will be strong, personal opinion!!!

Re: Repositioning the 3 support rollers on each side

Posted: Tue Mar 04, 2025 6:19 am

by Rob59

Hello HDP and Jofaur!

Thanks for your ideas!

Both options sound good to me, now I must think about which one to use.

Would repositioning those rolers really weaken the hull, even when I glue a poly strip behind all 3 rollers?

These are just support rollers, do they really face much pressure while driving around?

Doesn‘t the most pressure/force occur at the roadwheels/idlers?

Just thinking……

Thnkz anyway guys!!

Re: Repositioning the 3 support rollers on each side

Posted: Tue Mar 04, 2025 11:38 am

by Jofaur86

Hello, no I don't think it requires any particular effort? since it's just to support the caterpillars, then it's up to you to see

Re: Repositioning the 3 support rollers on each side

Posted: Tue Mar 04, 2025 12:32 pm

by Son of a gun-ner

Any destructive forces depend on the return rollers height in comparison to the sprocket and idler. Higher than either. There will be some downward pull. The same height or lower. Little to no strain. It will only be track weight. Unless you drive it like you stole it, then you would get track whip

Correct me if I am wrong, but I thought those return roller supports were only attached to the hull and can be removed? And Taigen sell spare metal supports

Re: Repositioning the 3 support rollers on each side

Posted: Tue Mar 04, 2025 1:16 pm

by Son of a gun-ner

Son of a gun-ner wrote: ↑Tue Mar 04, 2025 12:32 pm

Correct me if I am wrong, but I thought those return roller supports were only attached to the hull and can be removed? And Taigen sell spare metal supports

Turns out they are Mato

If you do want to order them, best do in now. They wont be around on the 7th for a couple of weeks.

https://www.forgebeartanks.com/store/p3 ... _Long.html

One other thing of note about possibly weakening the chassis. The front and back return roller mounts are right next to suspension mounts, the rear one being very close. Forgebear also sells metal suspension mounts.

https://www.forgebeartanks.com/store/p2 ... _Long.html

Re: Repositioning the 3 support rollers on each side

Posted: Tue Mar 04, 2025 5:44 pm

by Rob59

Well Mick, those return roller‘s axles are going through the lower hull. The rest is just glued onto it I think.

This StuG will not become an outdoor runner very often. This is my 5th StuG, and together with my early Ausf.- A these are the only ones without Schürzen.

The early one has a Taigen lower, metal hull so its rollers are positioned quite well.

So the reason for repositioning the rollers on this one, is just for the optical reason!

Thankz for pointing me towards the metal upgrade parts but I won‘t go for them.

This StuG will be another low budget project, with left over parts, like the metal Winterketten.

The metal sprocket and idler wheels I got from Ali.

There also will come a railing on the motordeck made from brass strips I do have laying around too.

The grills alongside the engine deck, I will cut out of a kitchen sieve, as always.

So the repositioning of the rollers will be the most exciting part of this build.

The crew, well, maybe some Winter Grenadiers laying on the engine deck.

We‘ll see.

Rob.