I have the intention of the parts to be screwed together where possible and I am going to upload all files to Thingiverse when it is been put together with little to no fettling to assemble'

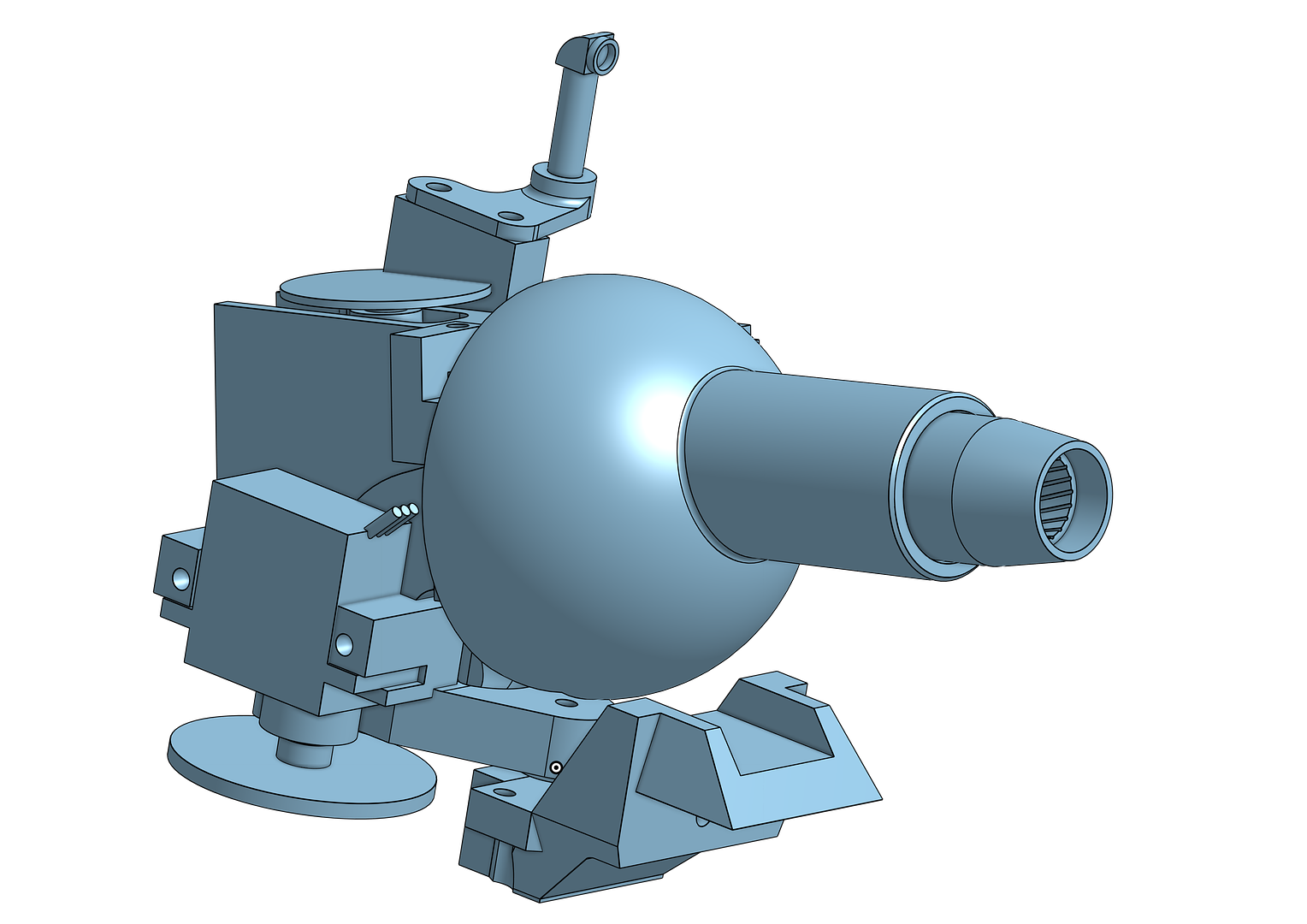

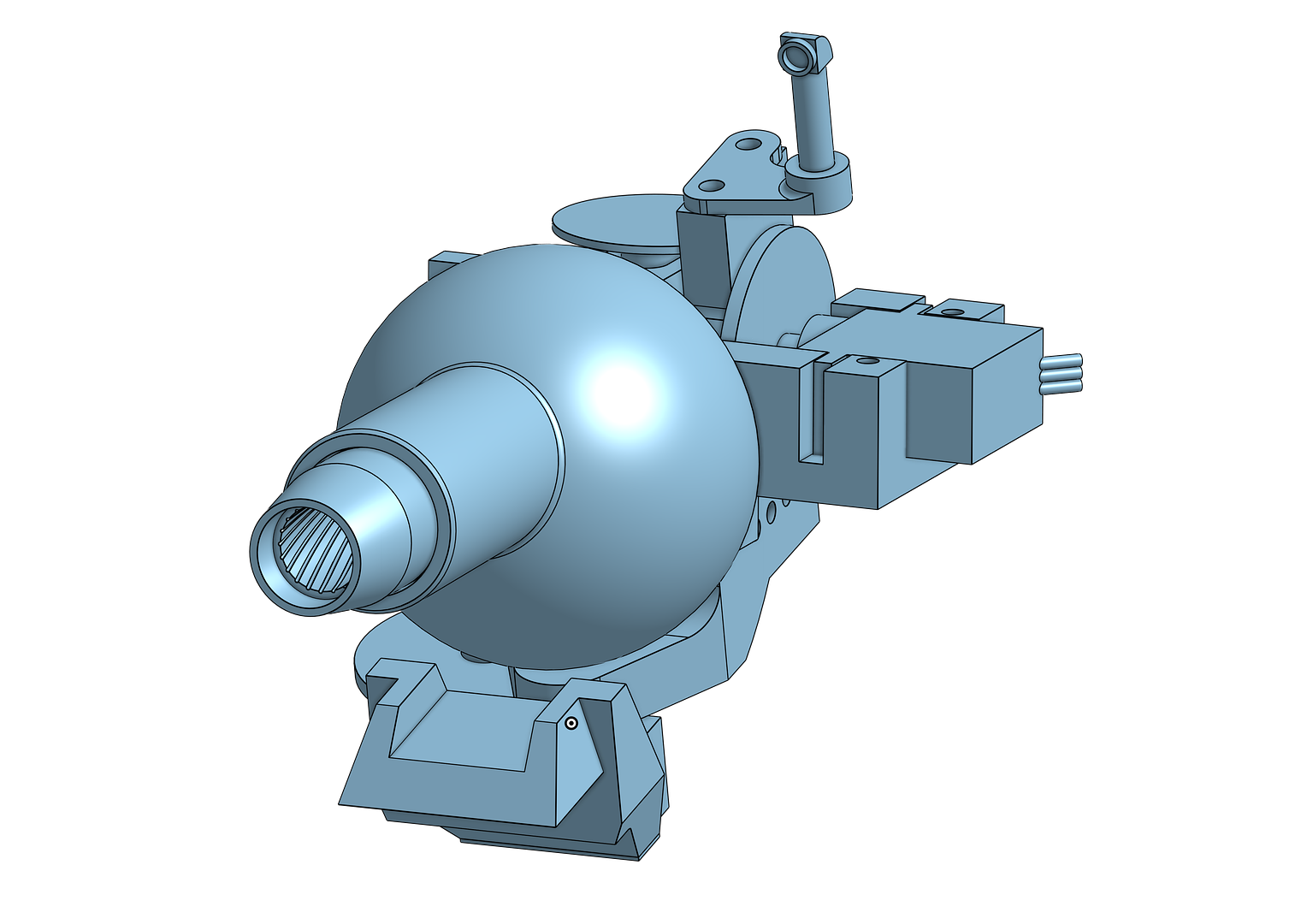

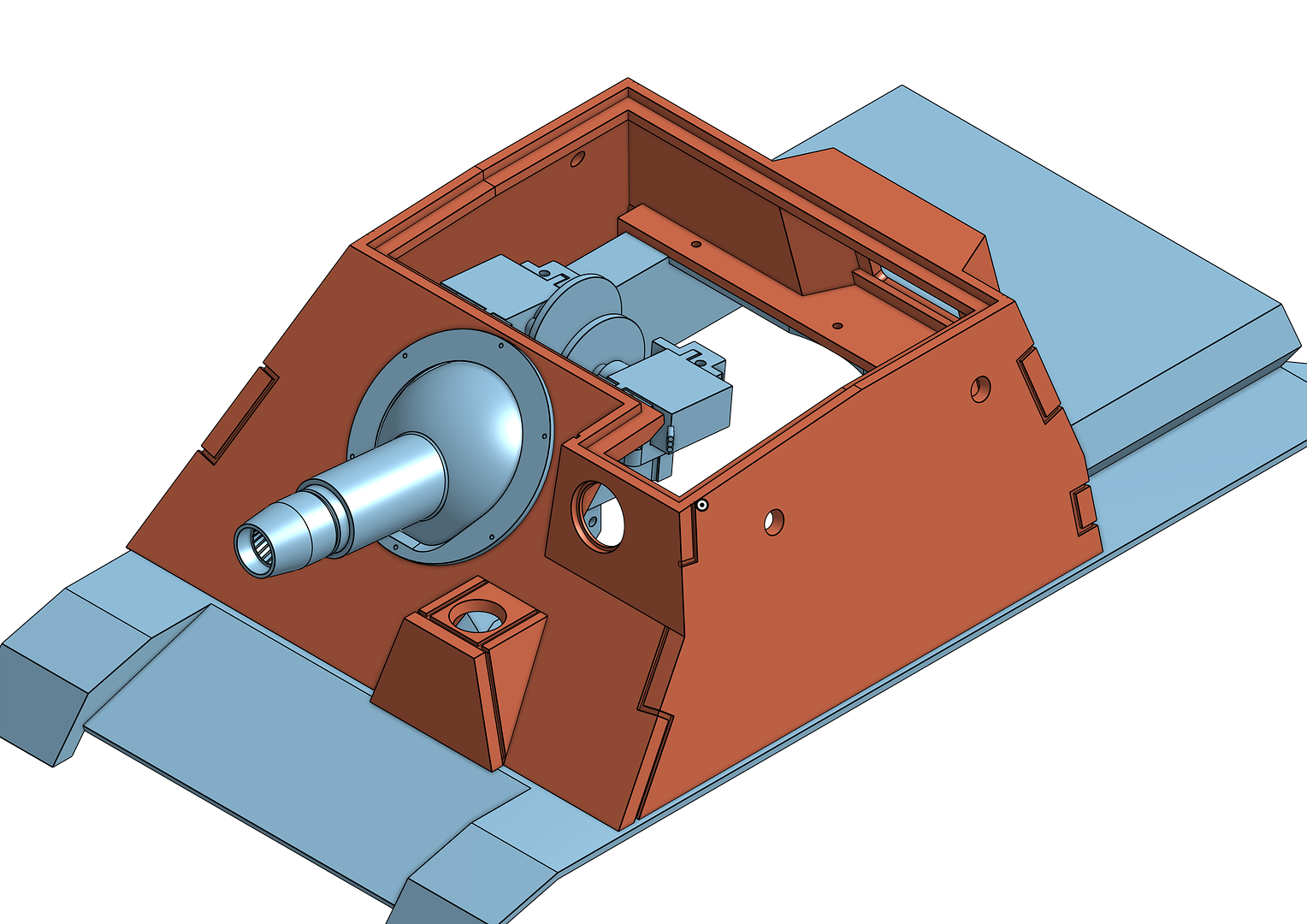

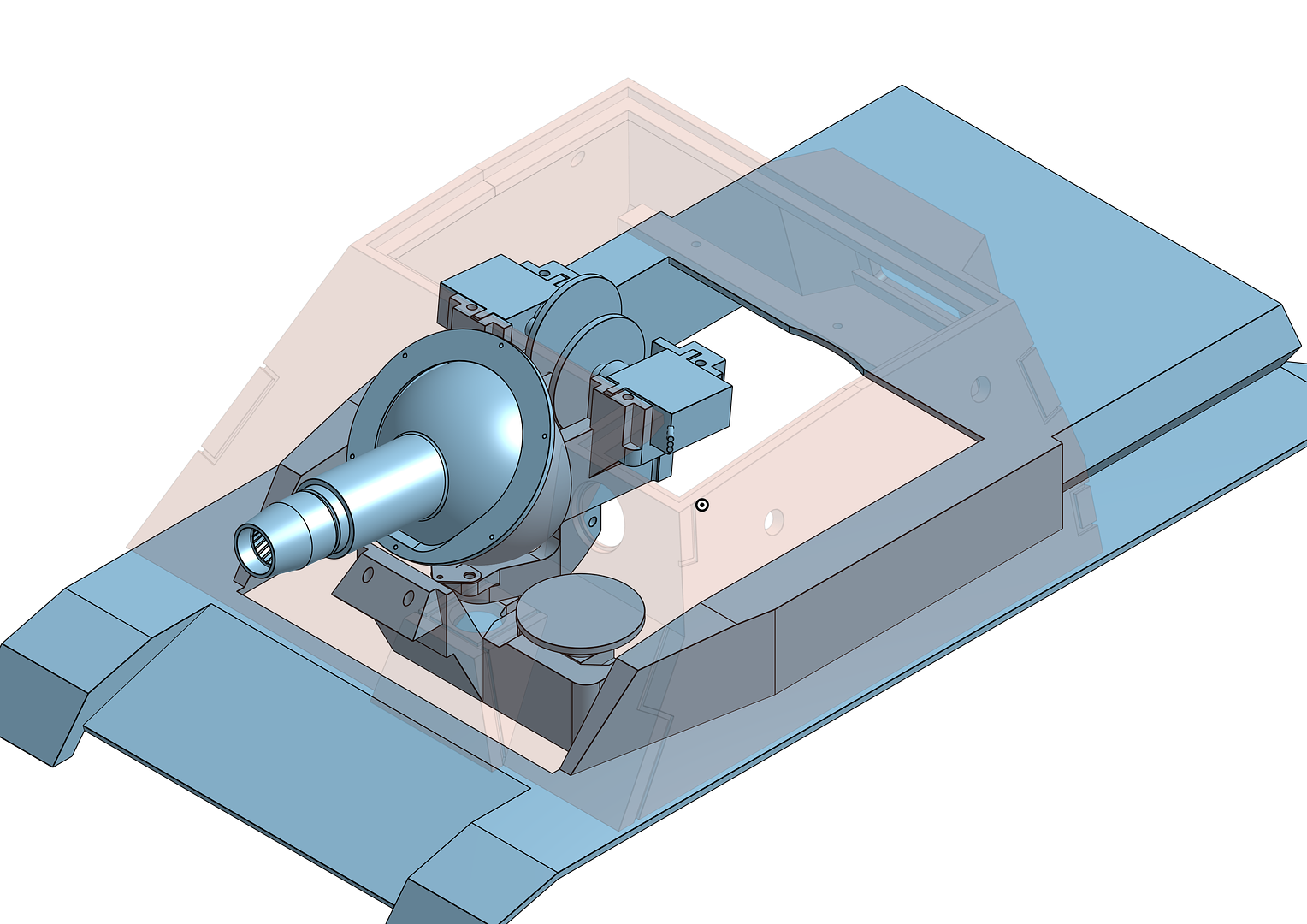

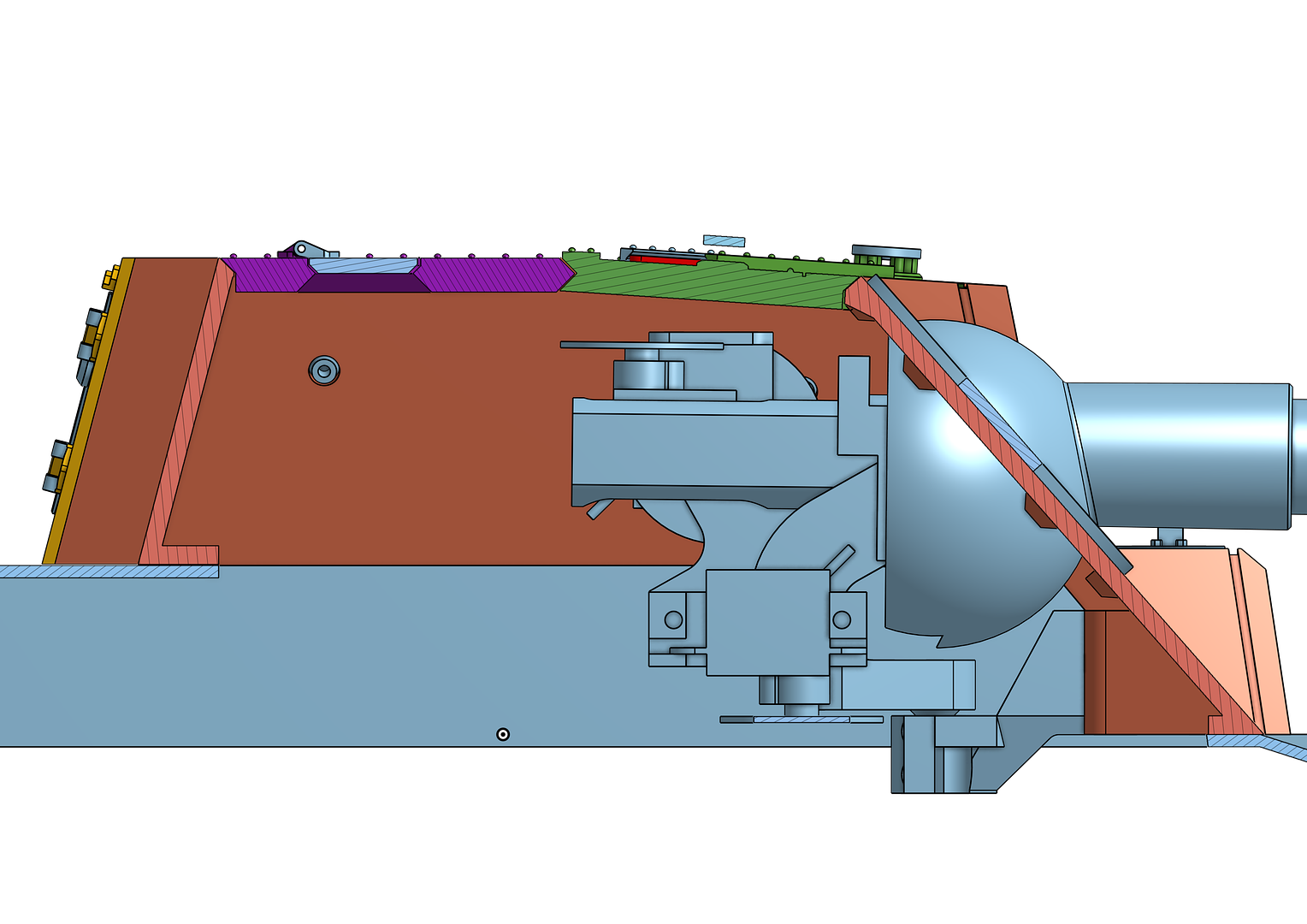

this is my first CAD model and starting point for the build.

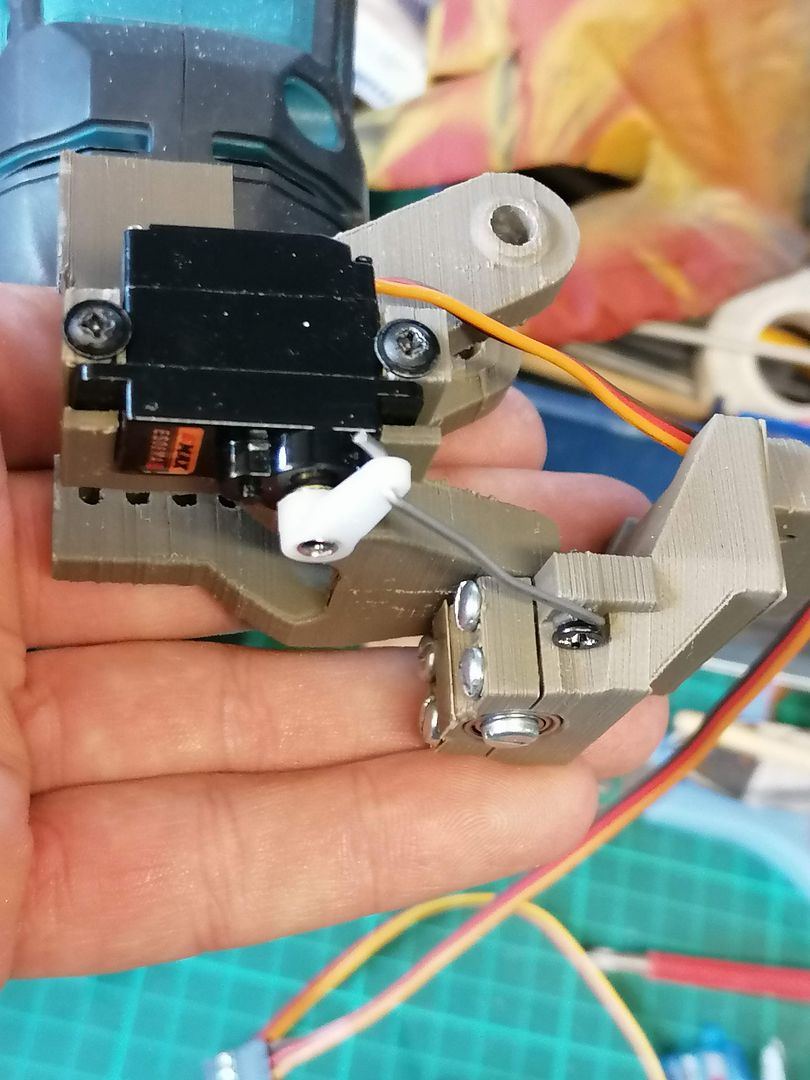

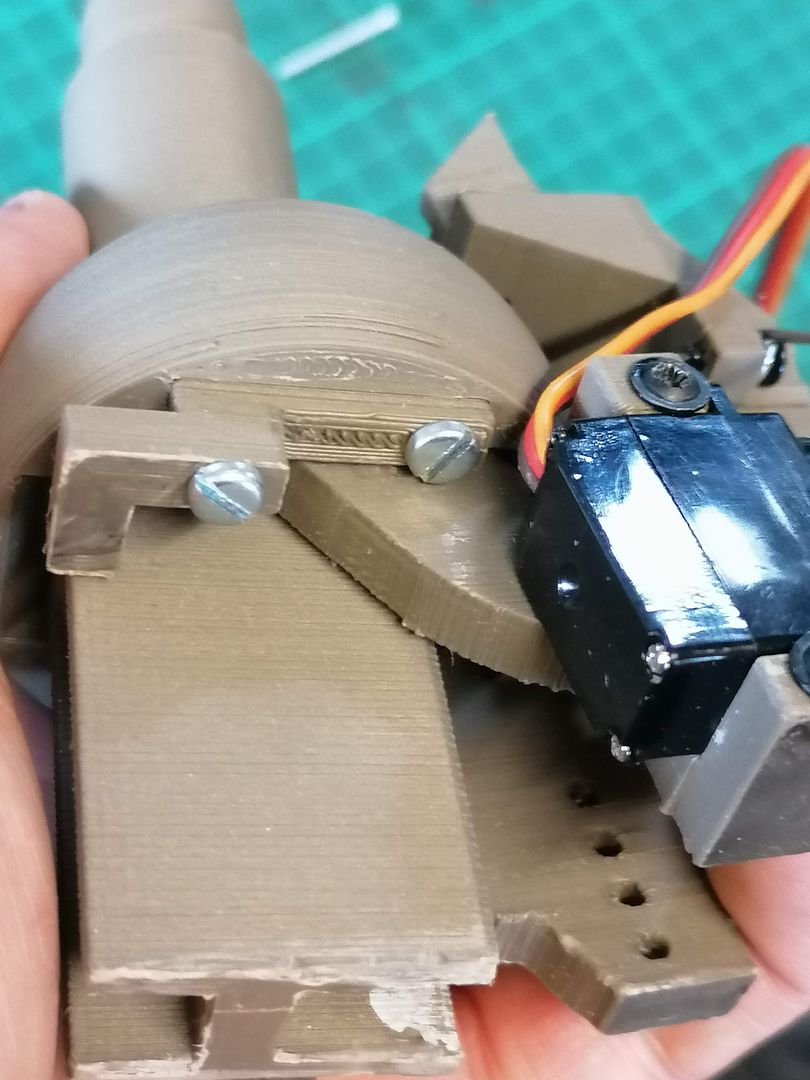

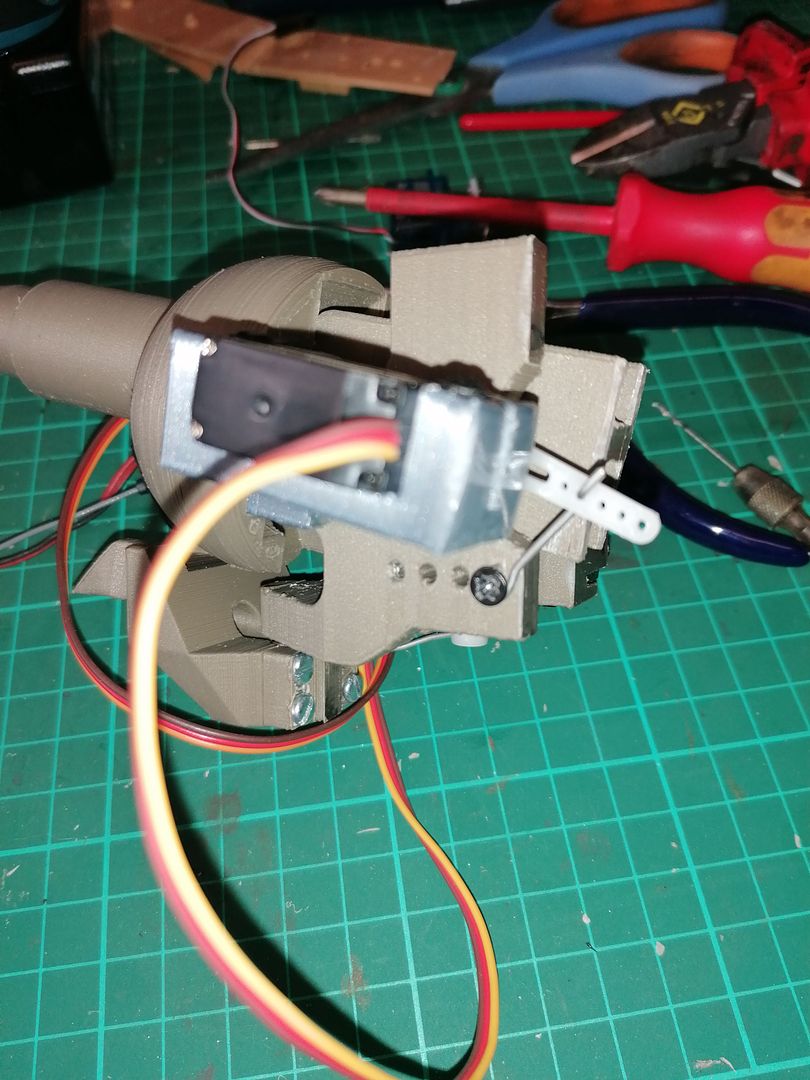

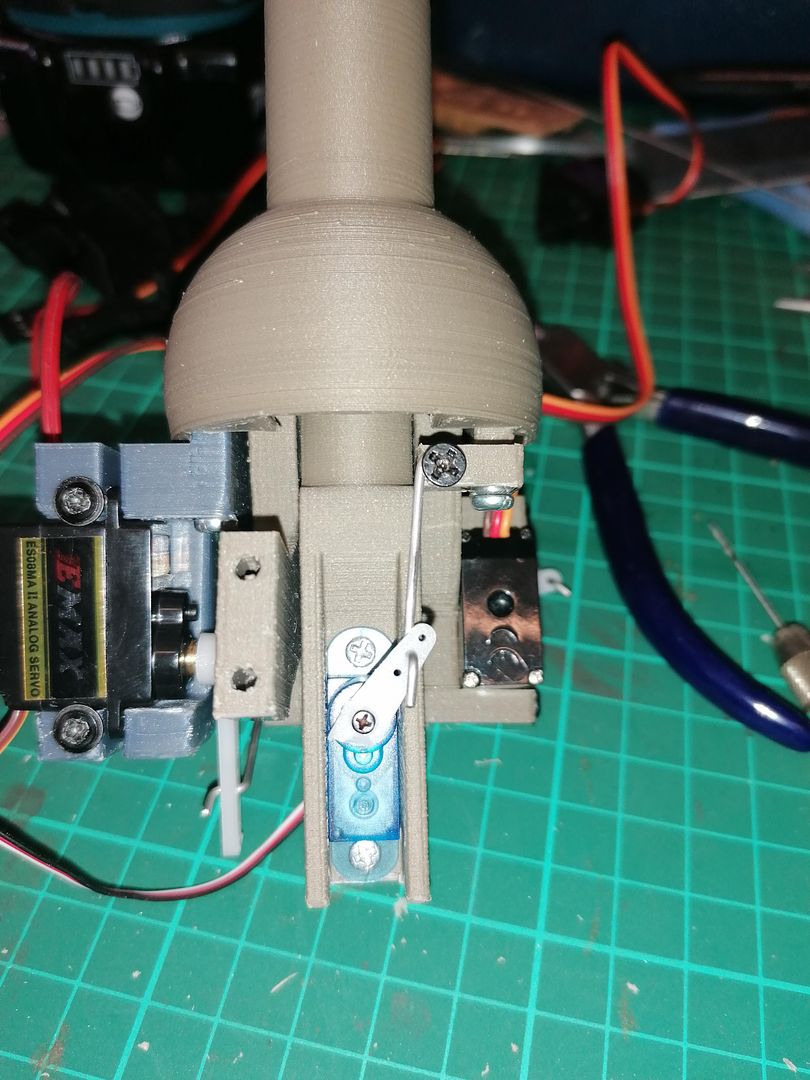

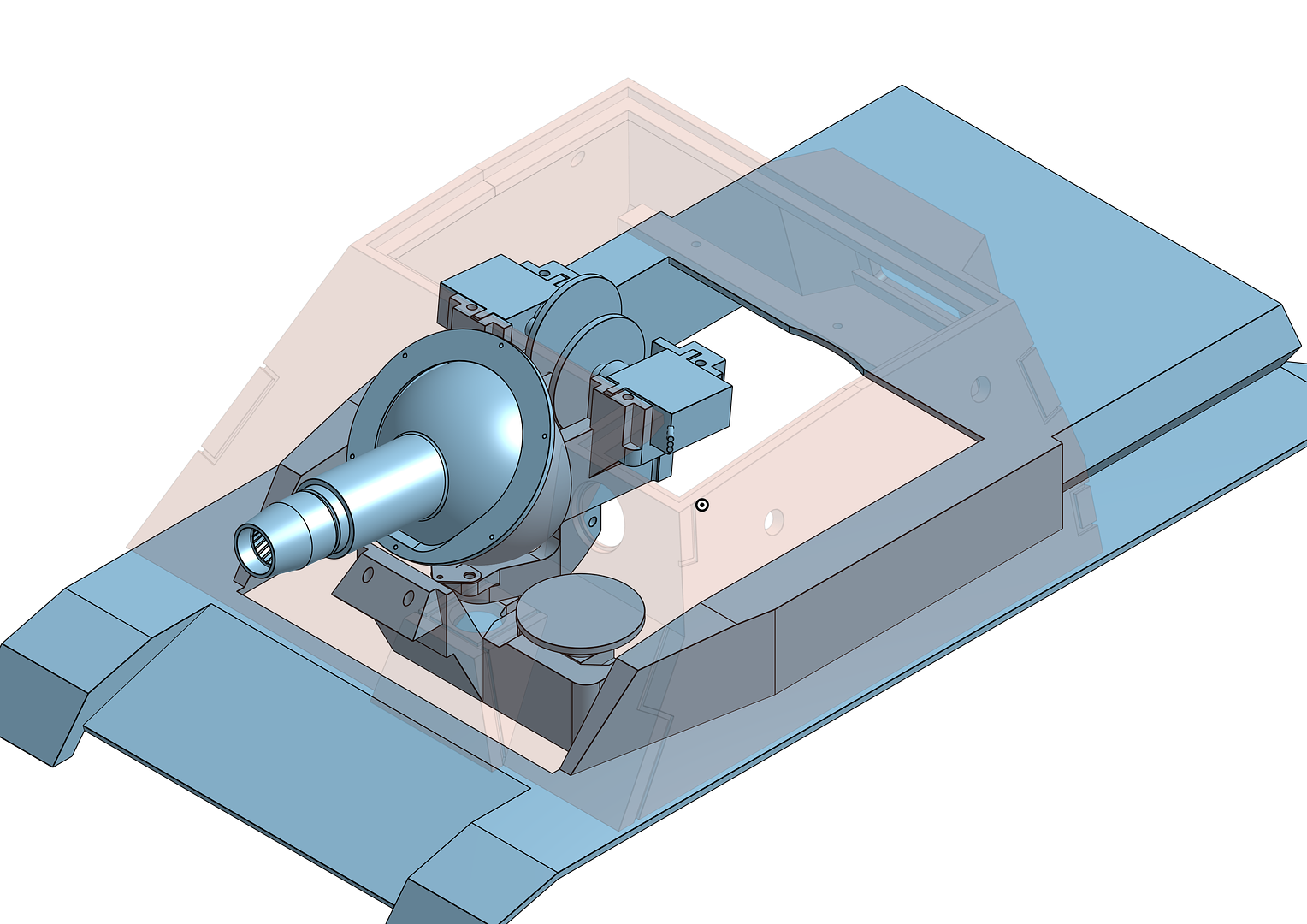

My intention is to make it have full movement with the gun plus recoil as i will be installing an IBU2U control board to run it.

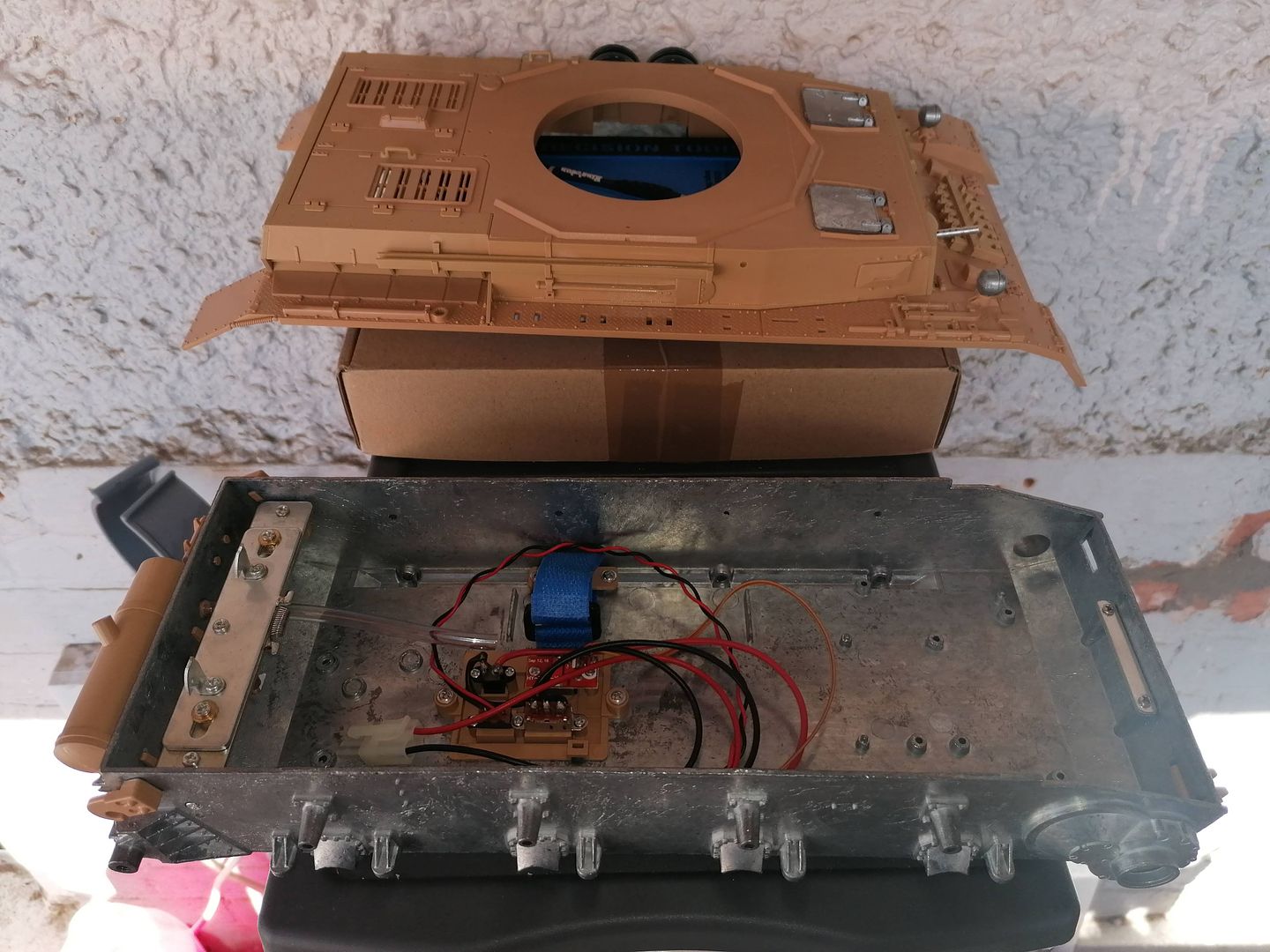

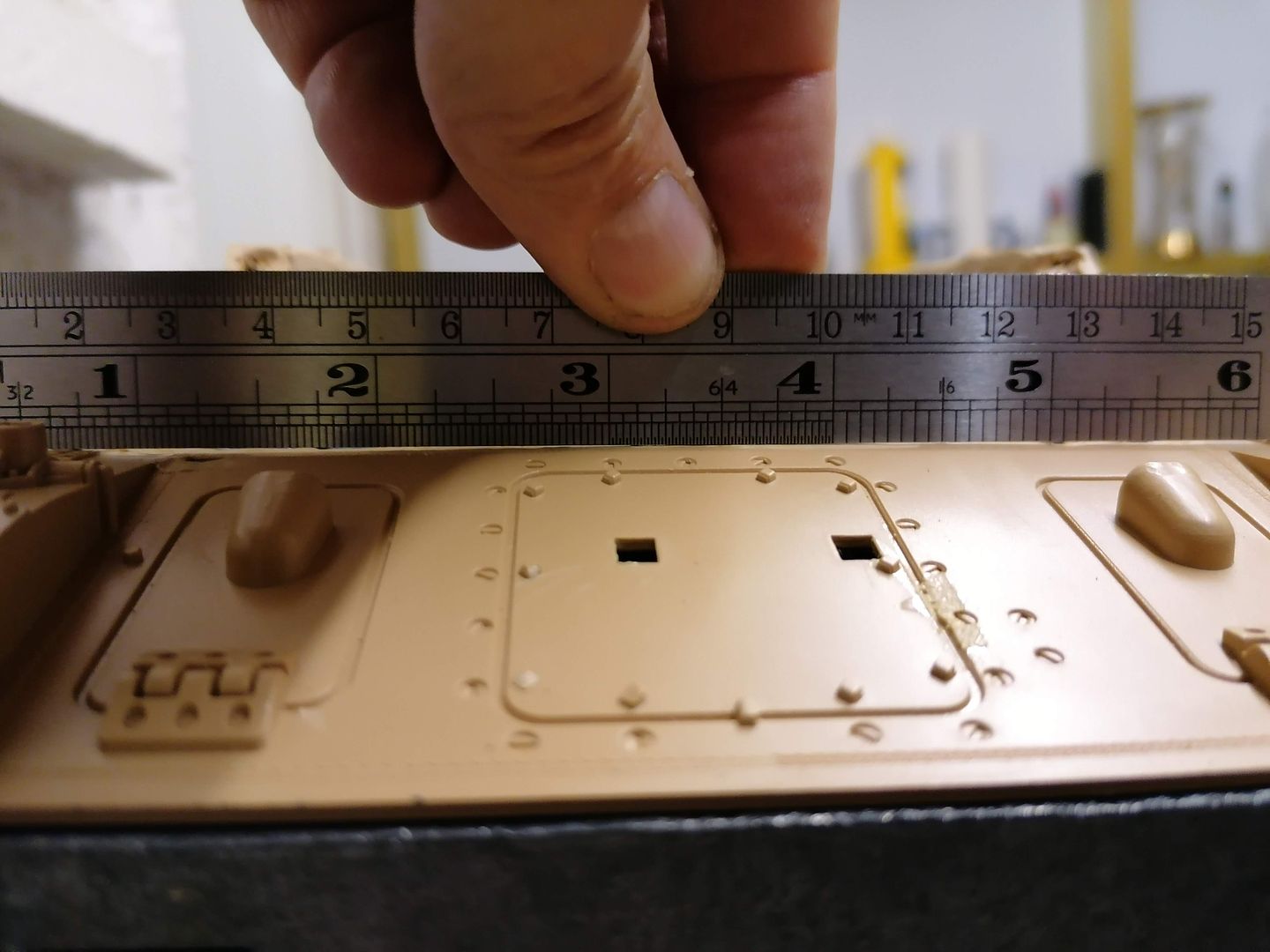

So it was time to spend some money and I ordered a Taigen Pz4 metal lower hull and upper hull as i didnt need the whole tank to get started on the project.

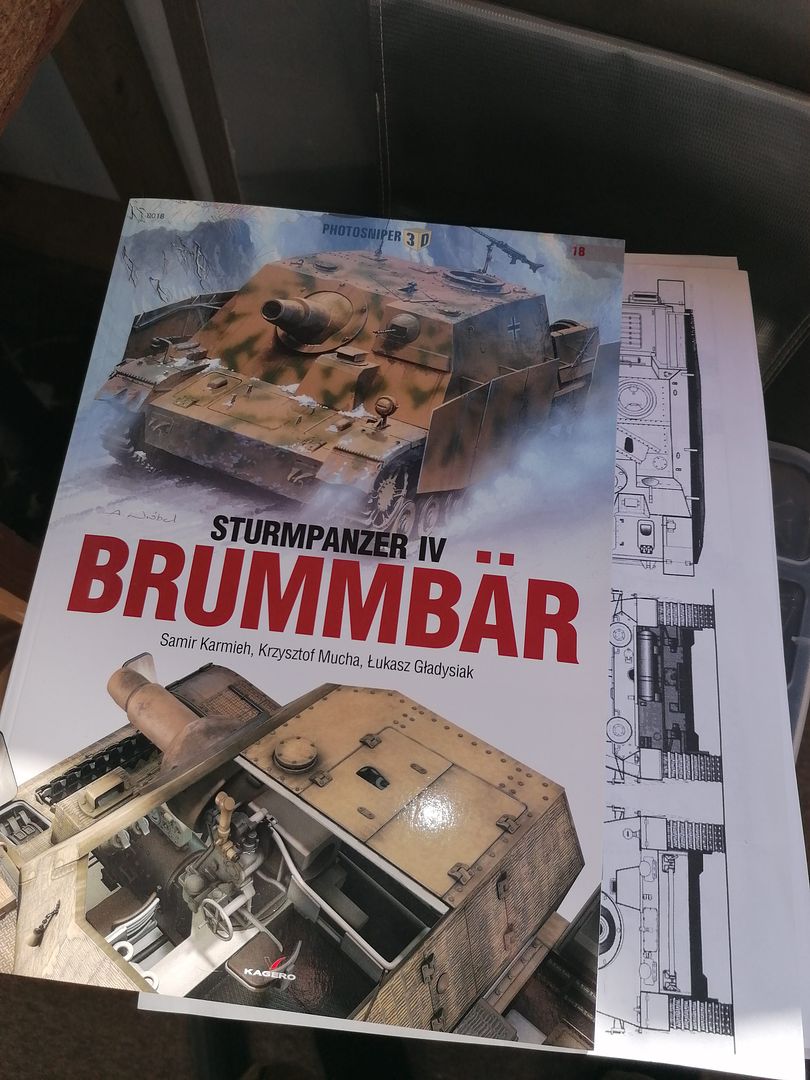

And a book to help with the build.

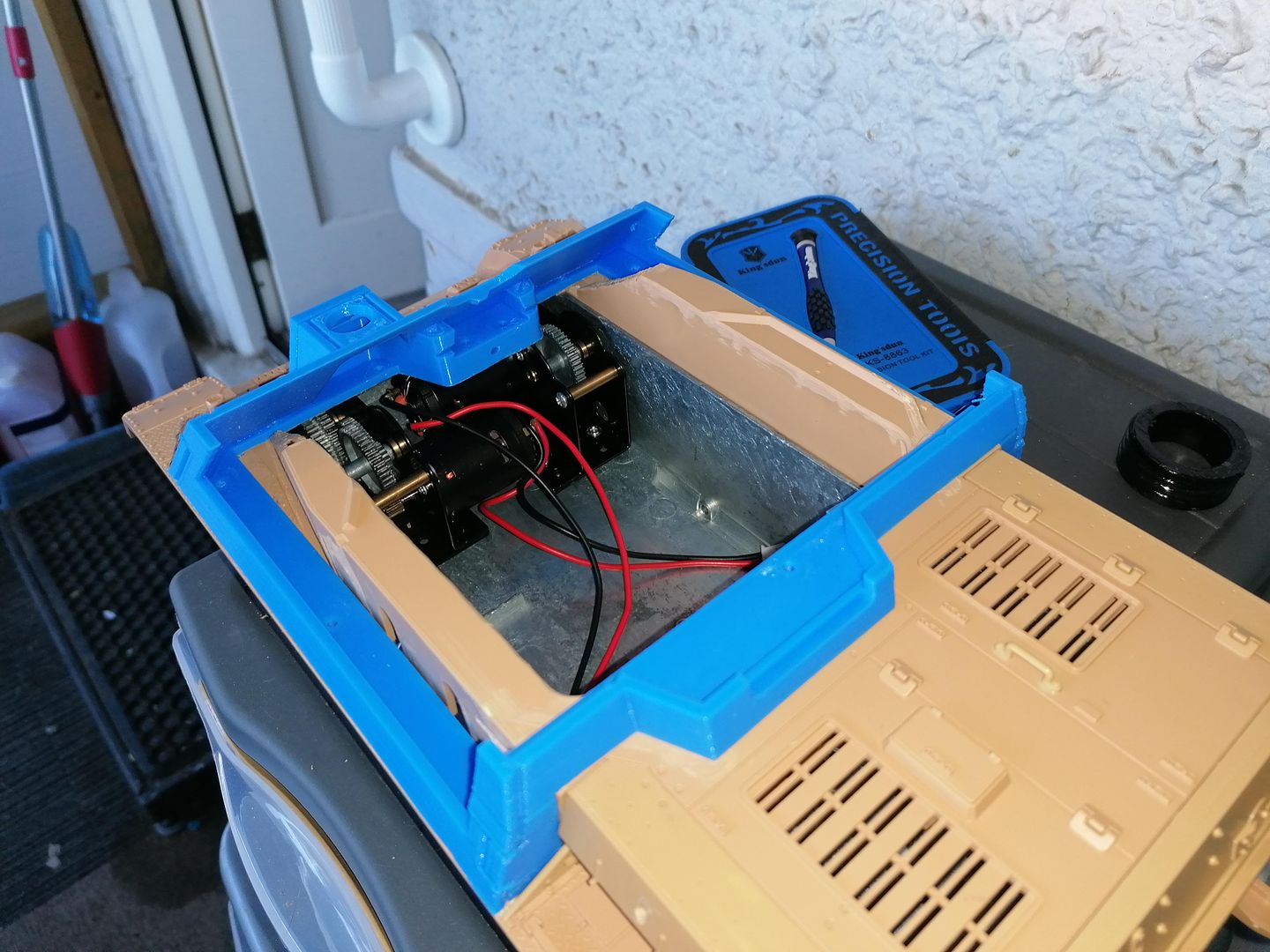

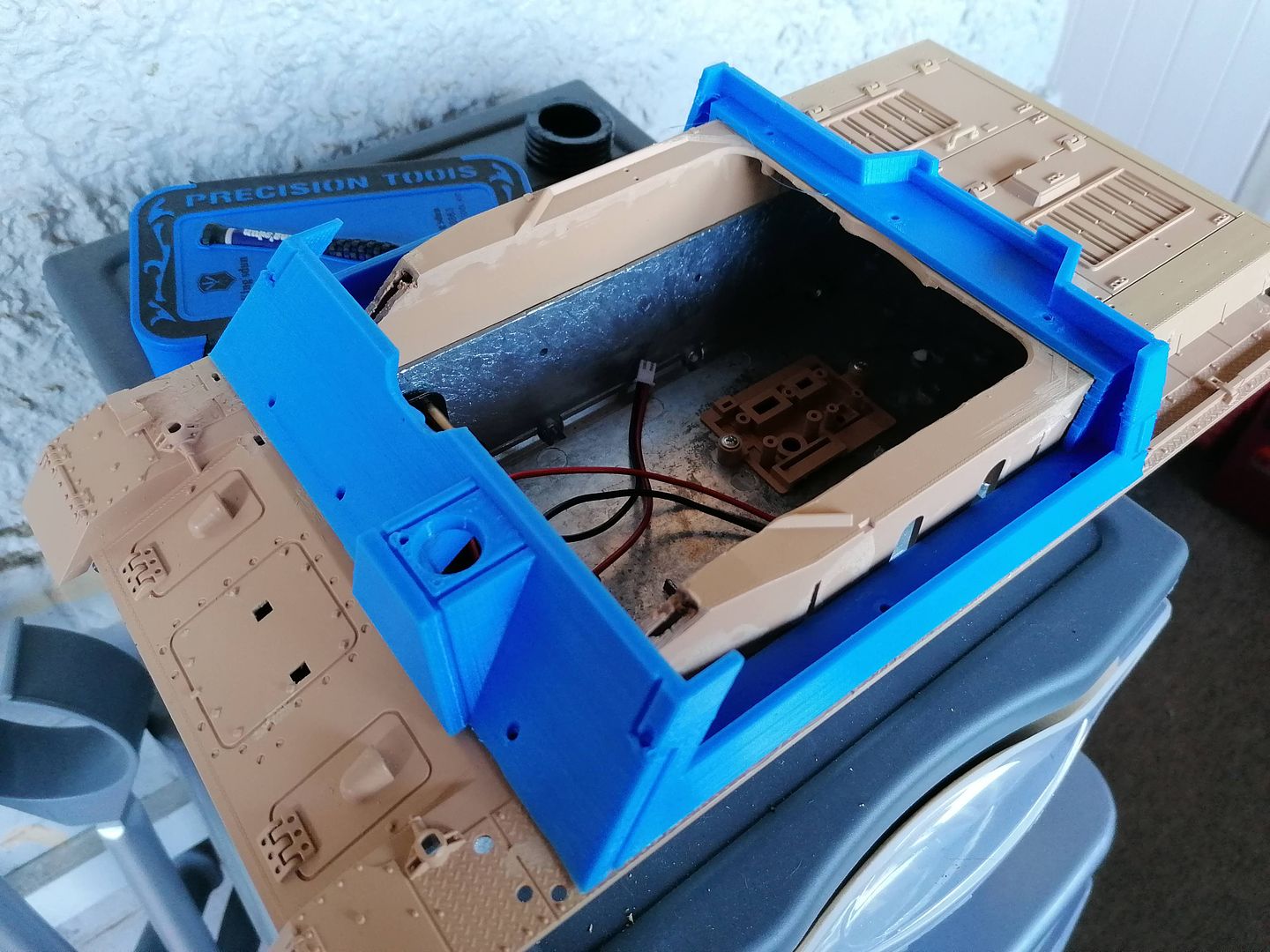

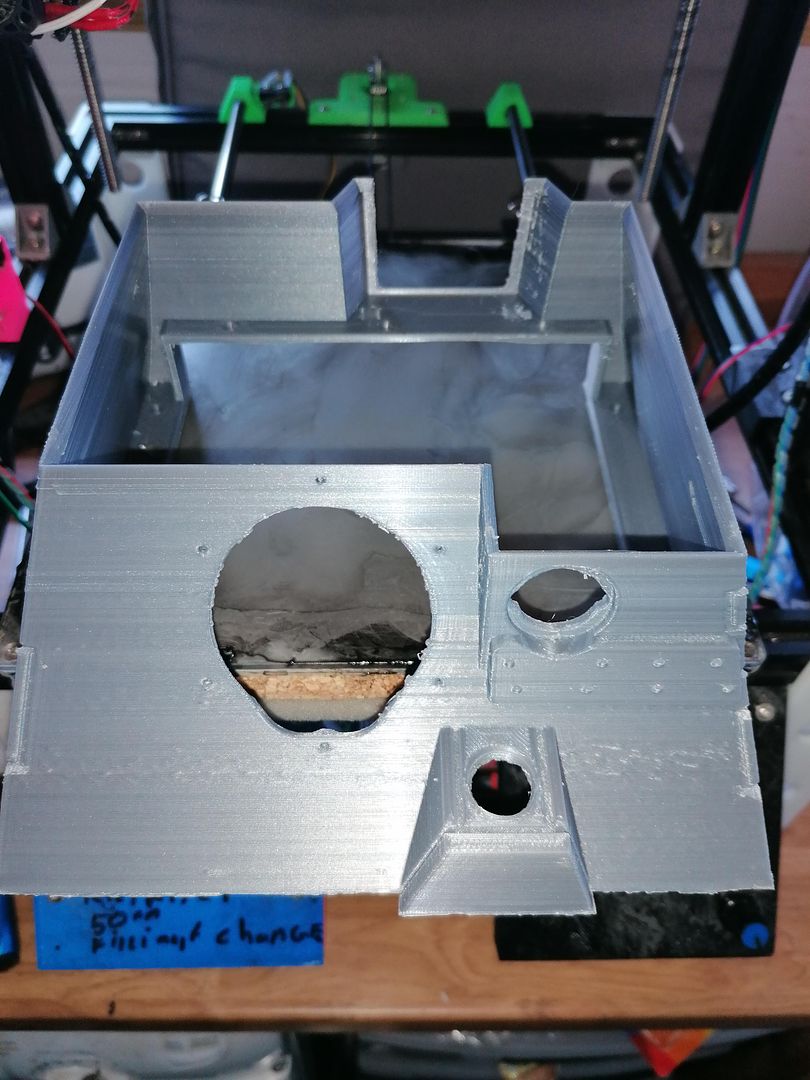

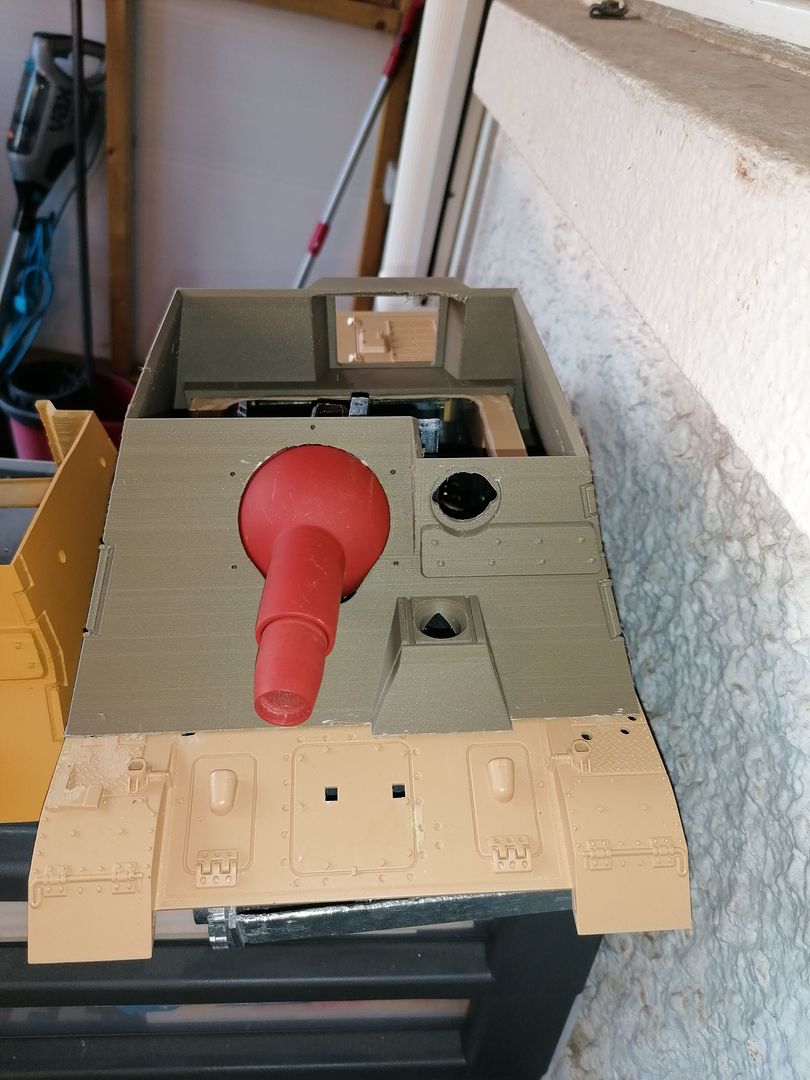

So with my plan coming together it was time to fire up the printer and print a footprint of the citadel to make sure it fitted after all the side moulded parts are removed from the front section of the hull and to work out were the hull needed cutting to accommodate it as well as a drilling guide to drill 3mm holes in the hull for fixing the citadel to the hullfor ease of fitting.

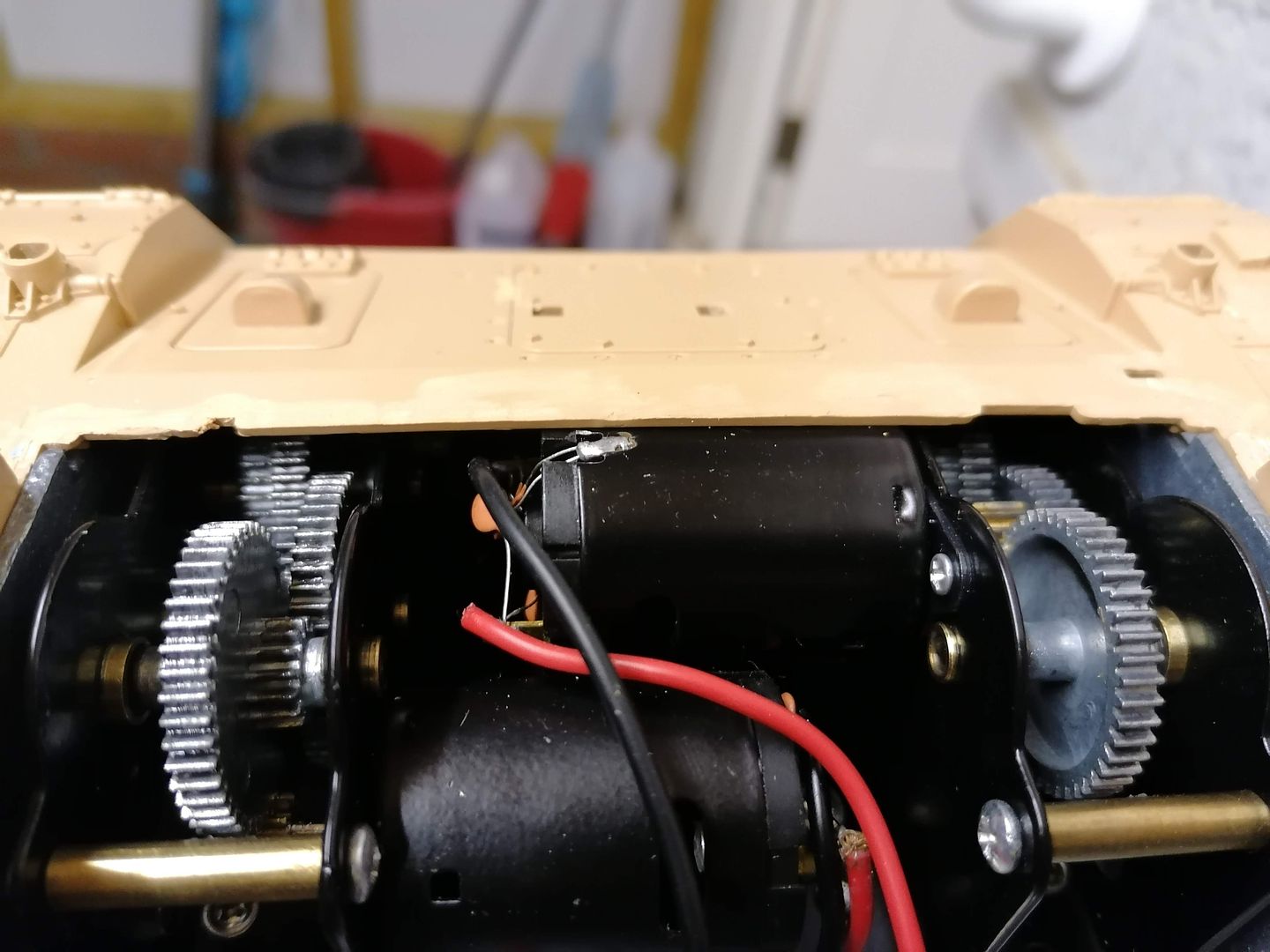

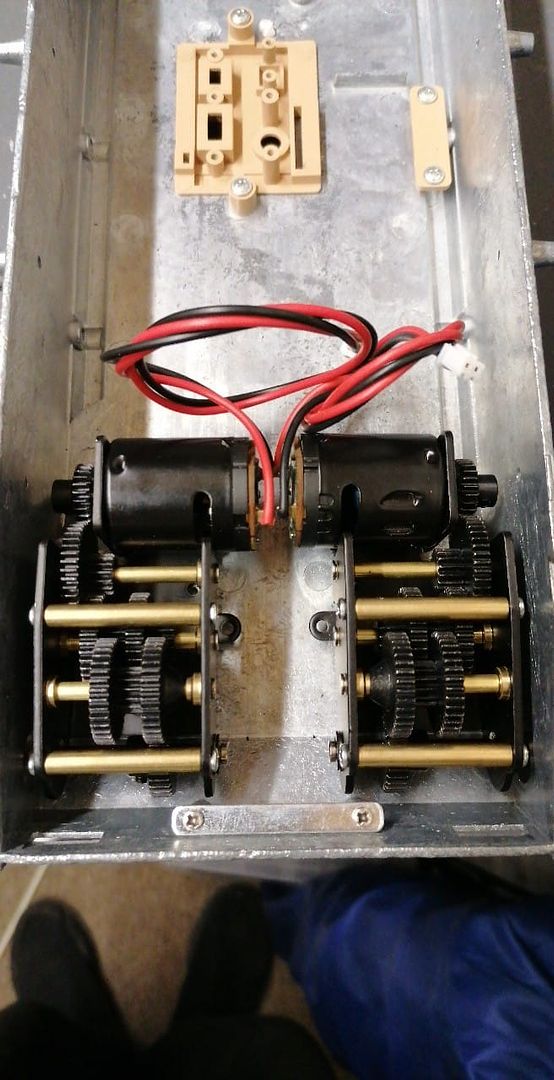

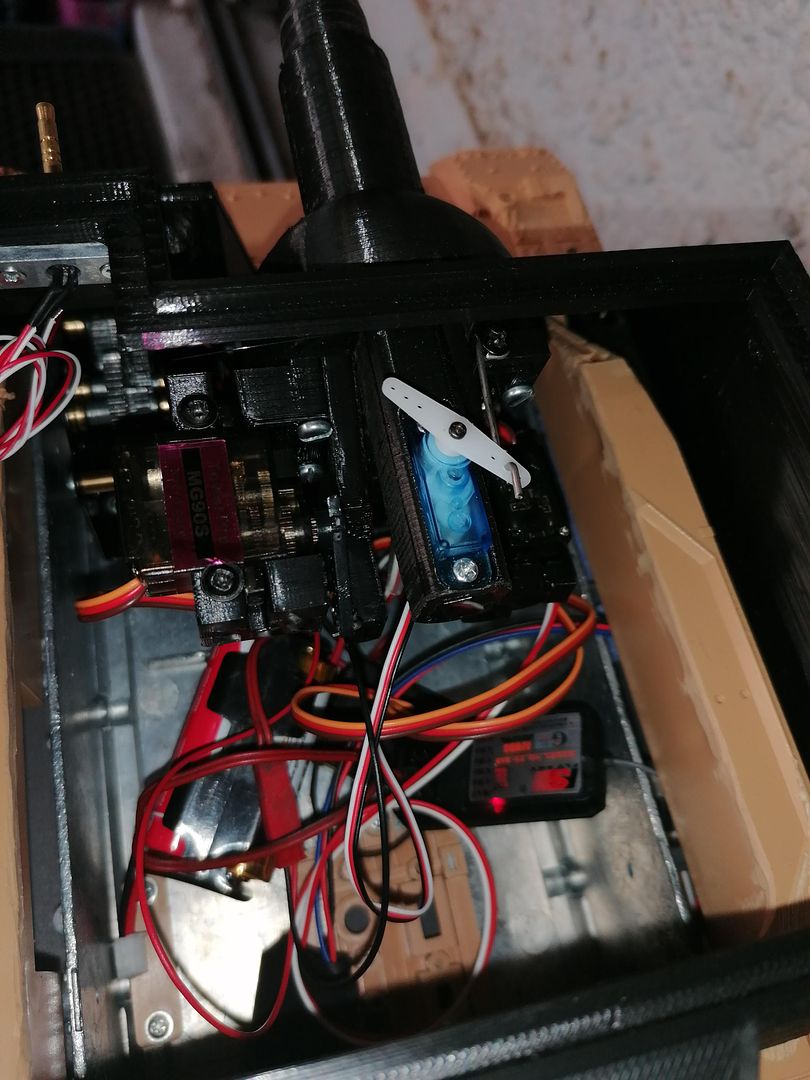

My first worry was the gearboxes I had taken out of my Sturmtiger and fitted in the Pz4 hull were hitting the hull and pushing it up slightly.

So after using a set on my sturmtiger I got a set of Taigen flat style gearboxes as I didnt want any fouling when i fit the gun into it later.

All tough they do pose a few problems of their own when it comes to fitting the two hull halves together but I will sort that out when Ihave the main parts done.

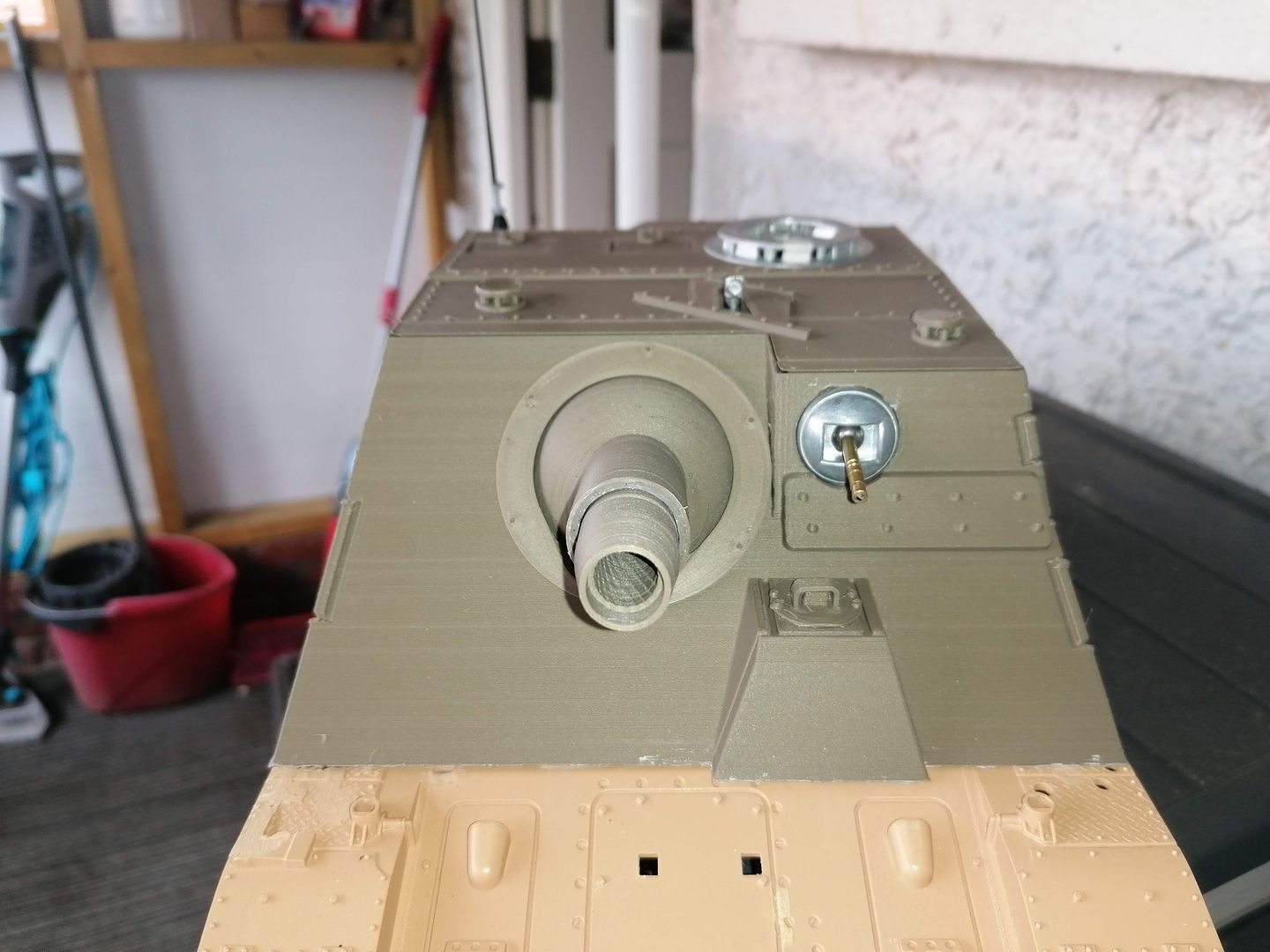

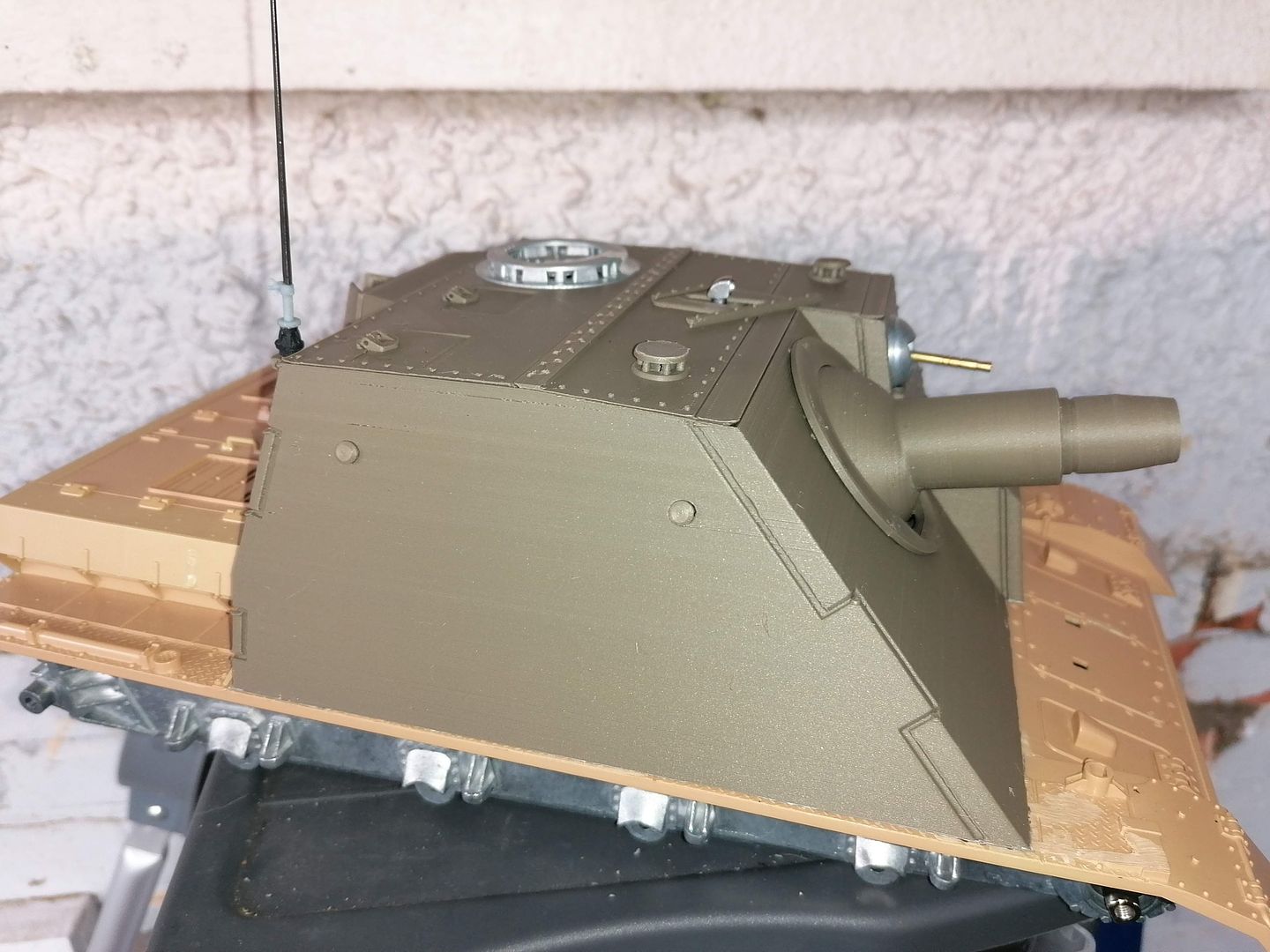

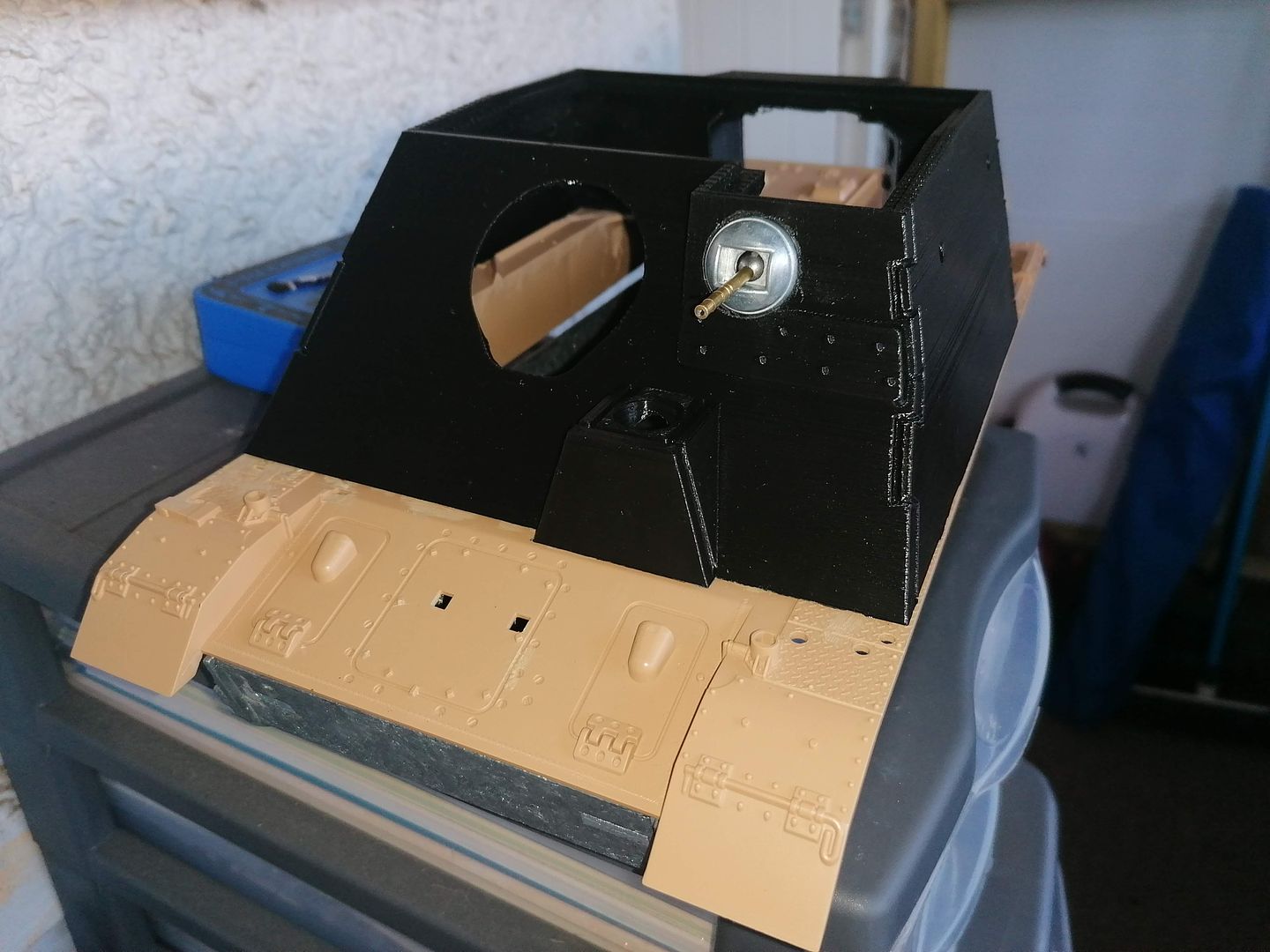

This is the first edition of the upper section with a metal tiger 1 machine gun in place for a trial fit.

I wasnt happy with the way Iwas going to fit the top peices on to a shelf it wouldnt have been easy to get a detailed look at the edgesI gave the very top edge a design change and removed the shelf and replaced it with a tapered edge and my plan was to taper the edge of the upper sections and sit them on top and fit magnets to easily remove them.

It looks rough as the filament wasnt very good and my settings were not that great but it gave me something to work on.

and with a bit of spray filler and sanding it didnt look too bad especially when i got the first set of roofs done.

But the poor results from the printing caused me to splash out on some better quality PLA filament and do some sorting of the settings on my slicer software before i did anymore printing of citadels.

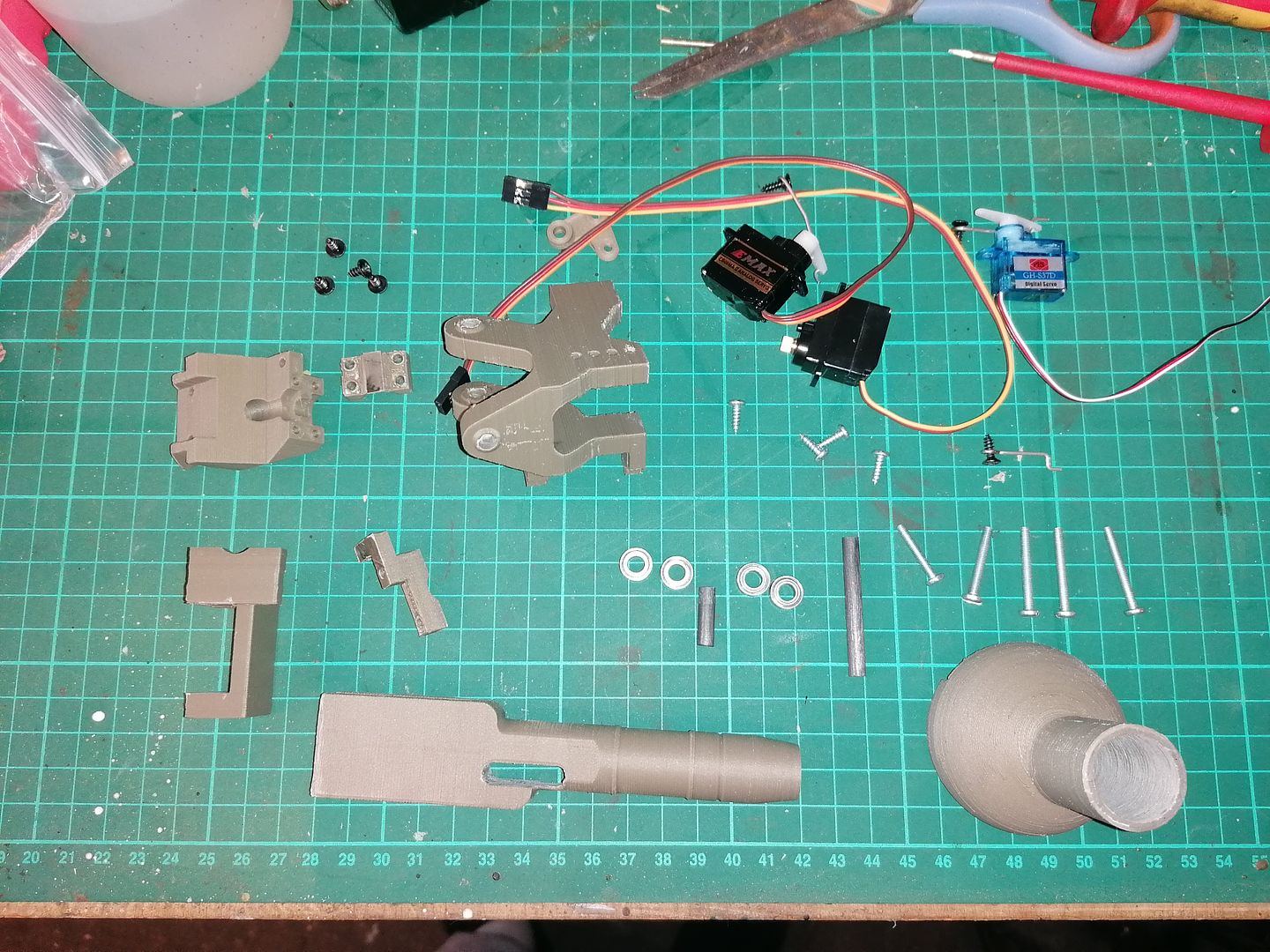

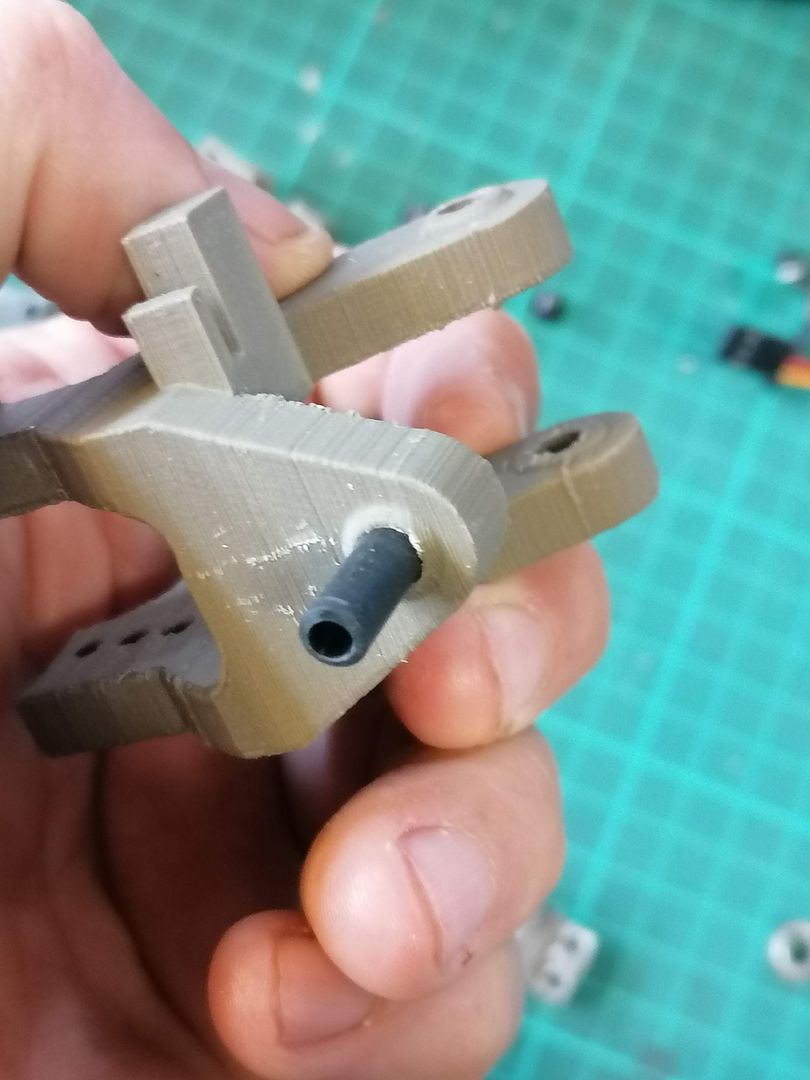

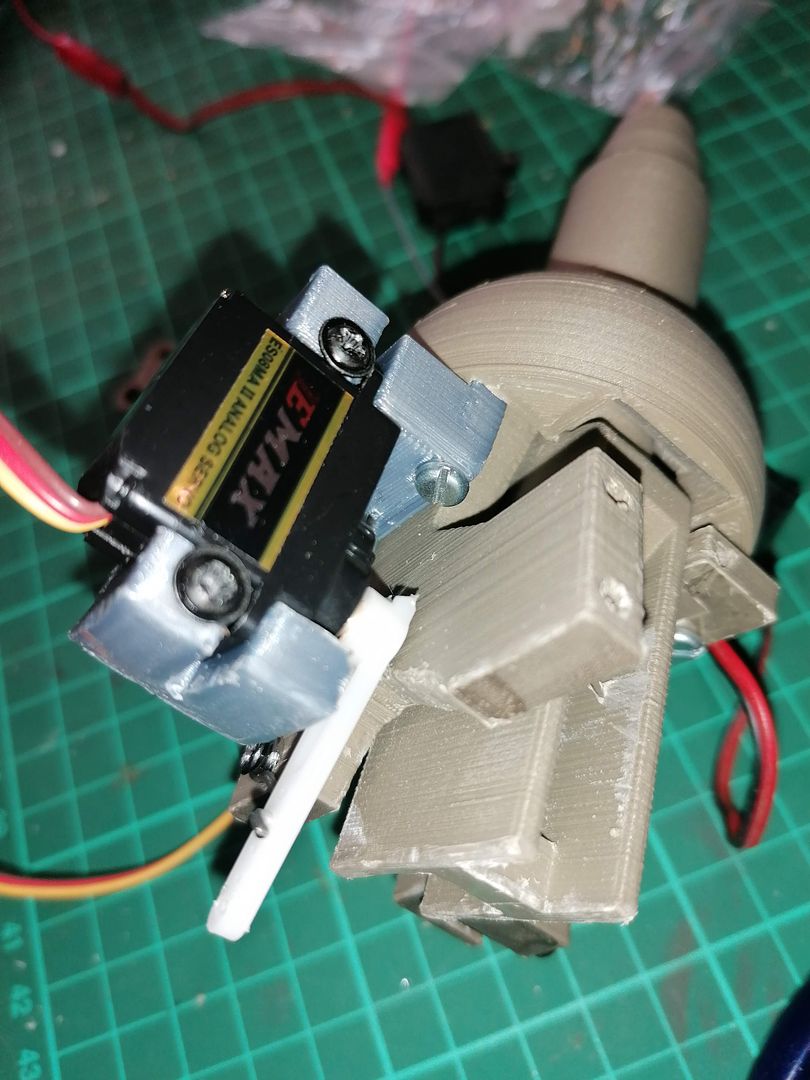

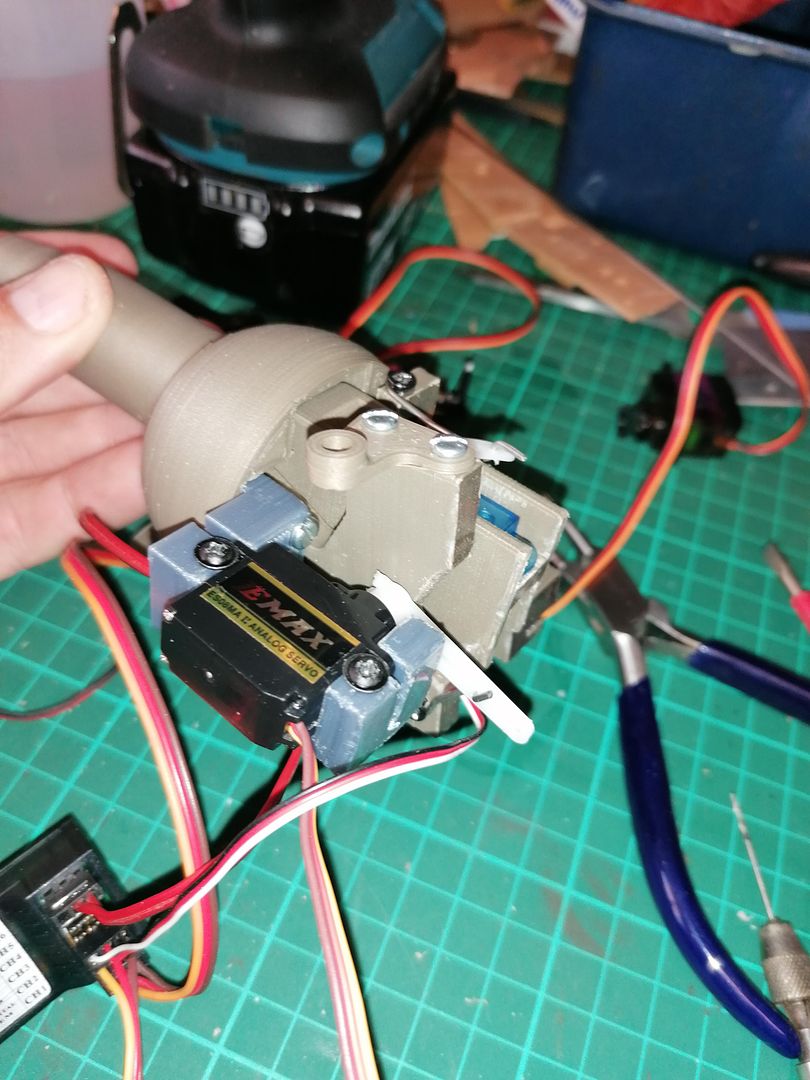

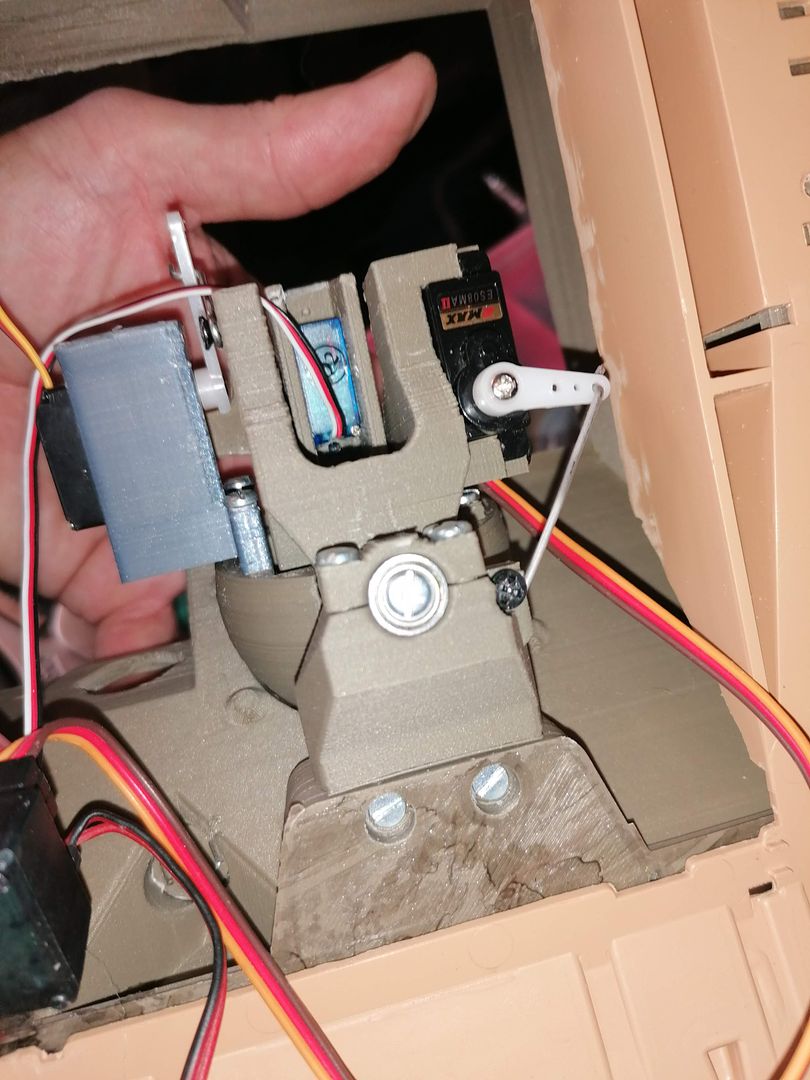

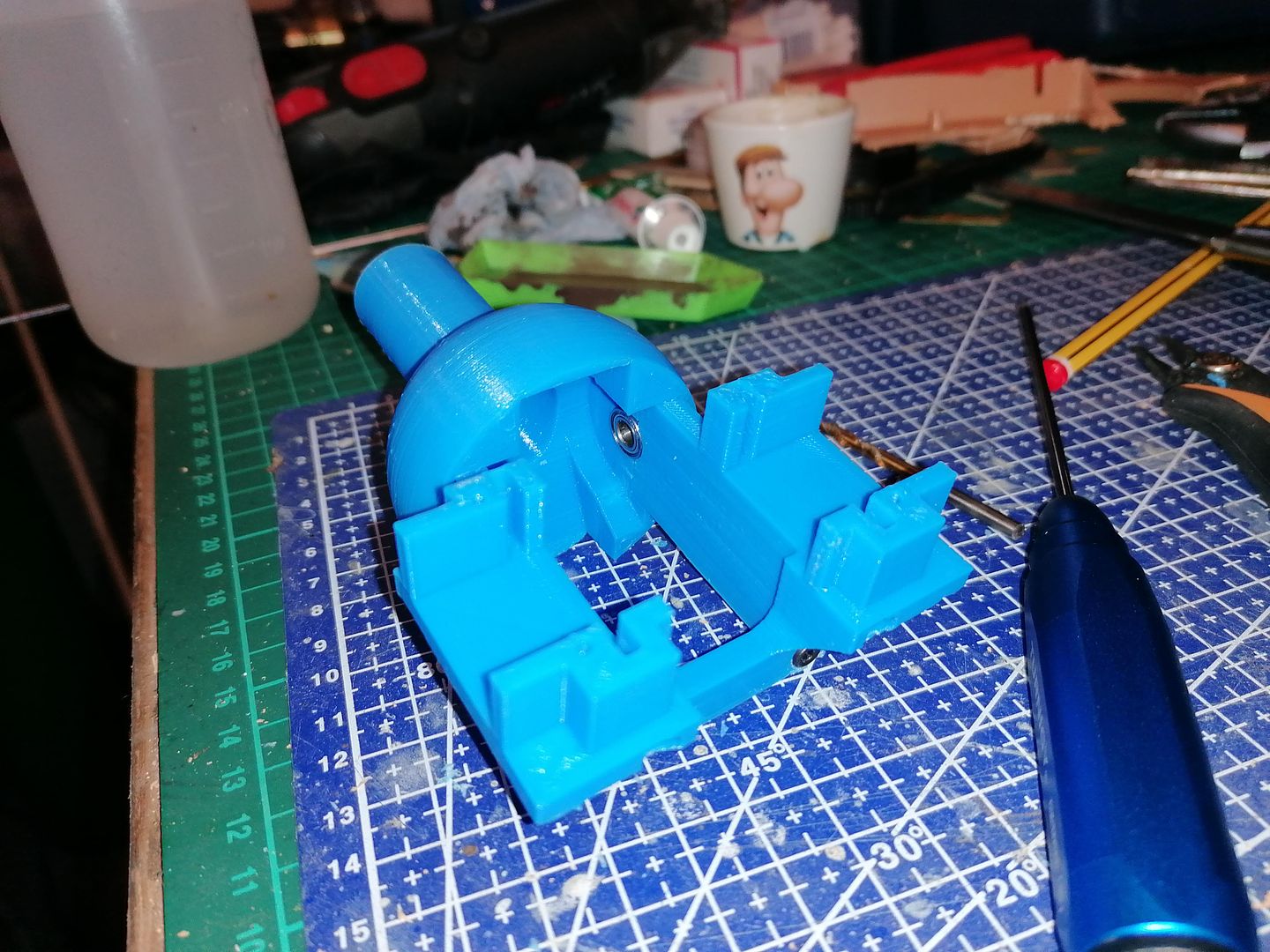

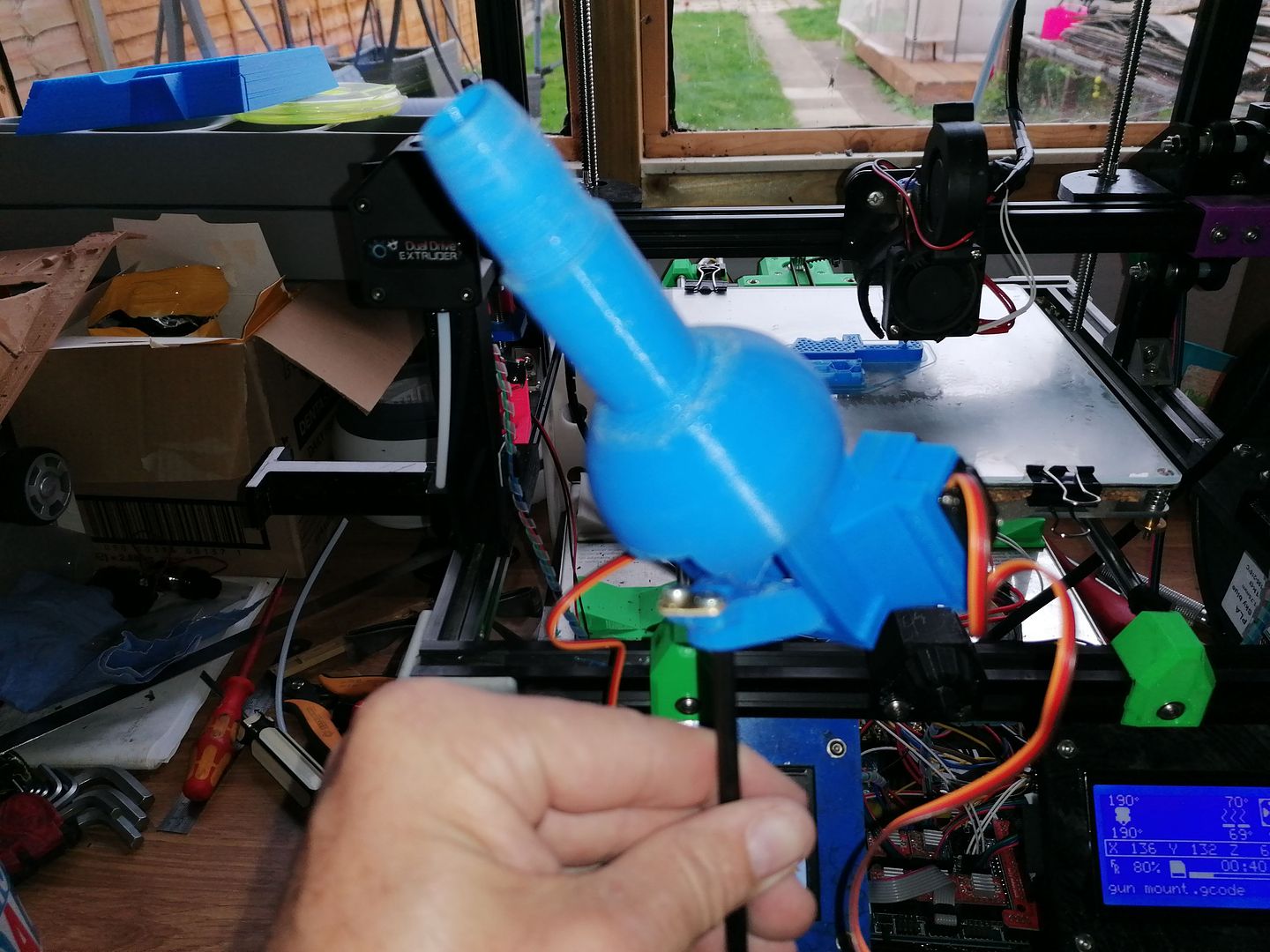

Idid however have enough of a decent filament to print of a gun assembly.

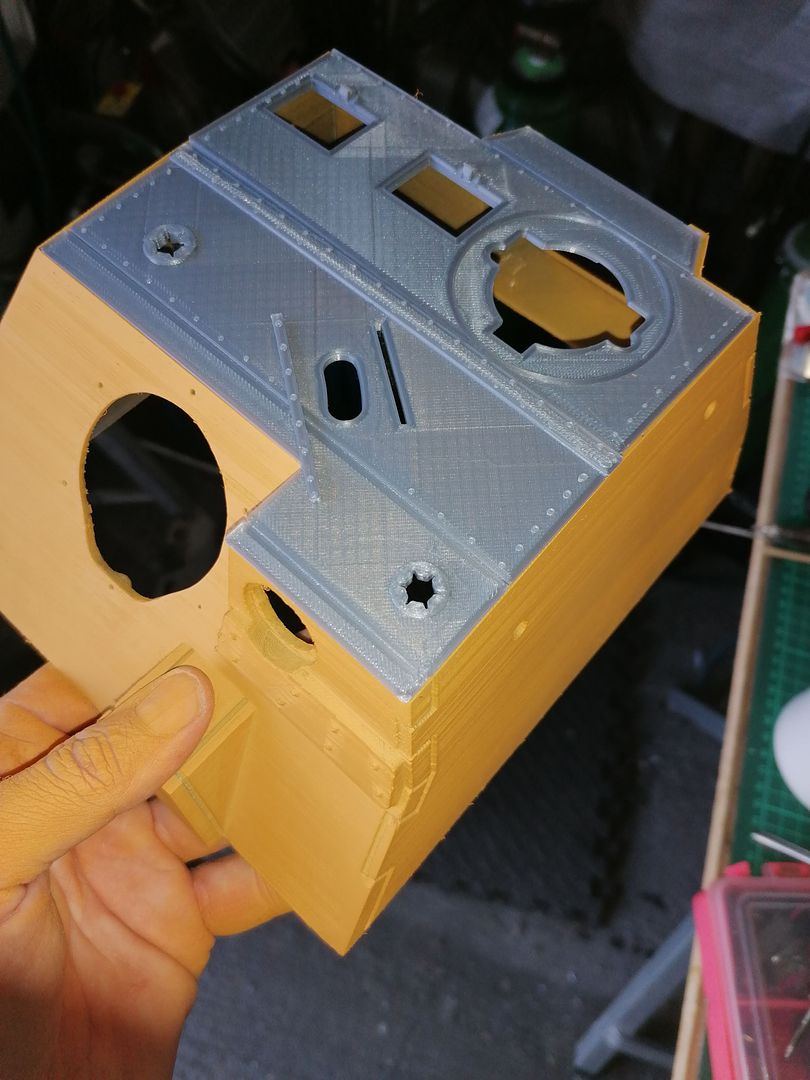

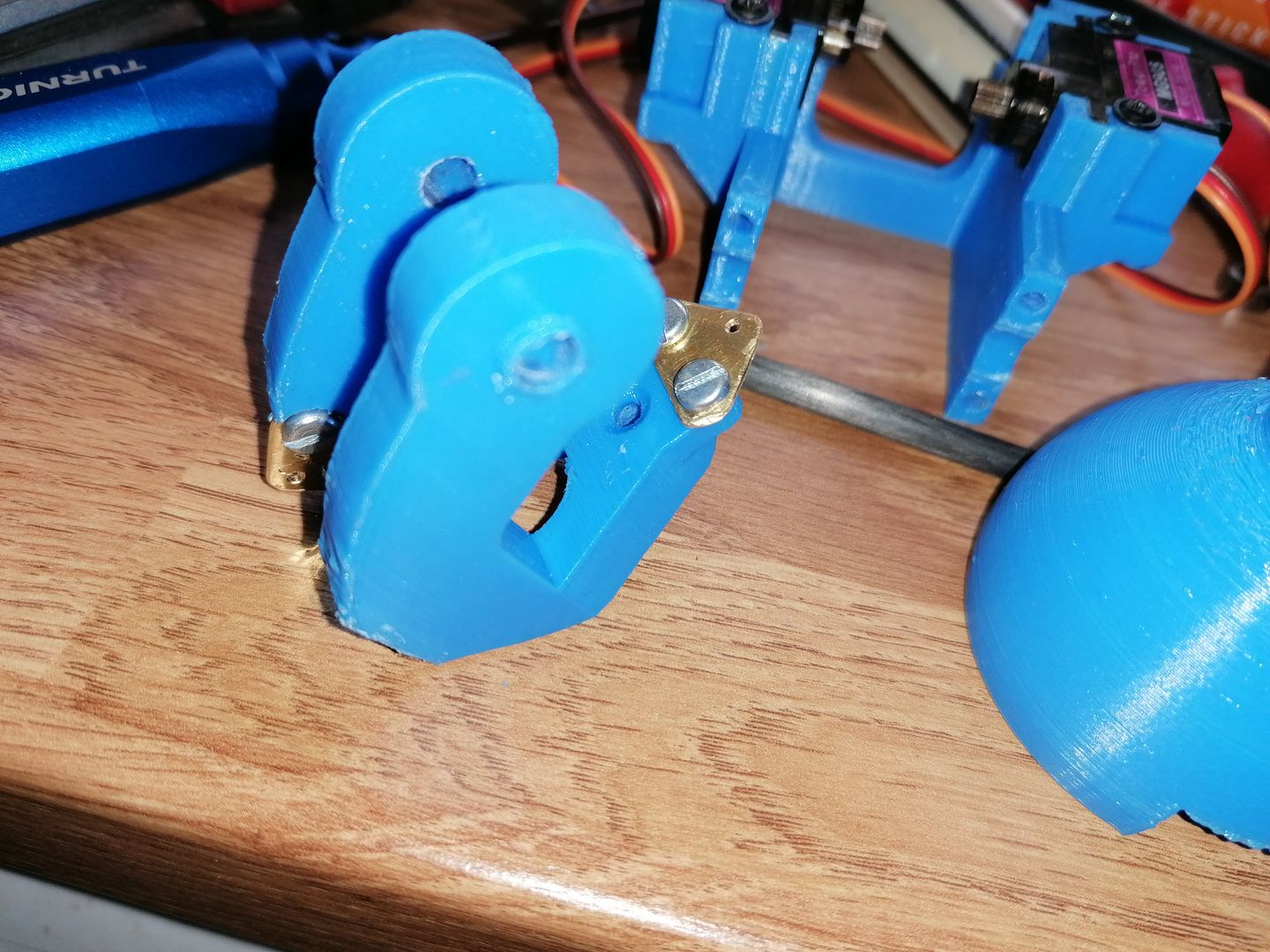

This was my first gun setup but when it was printed it soon became clear it gave the gun no space to move about in the confined space.

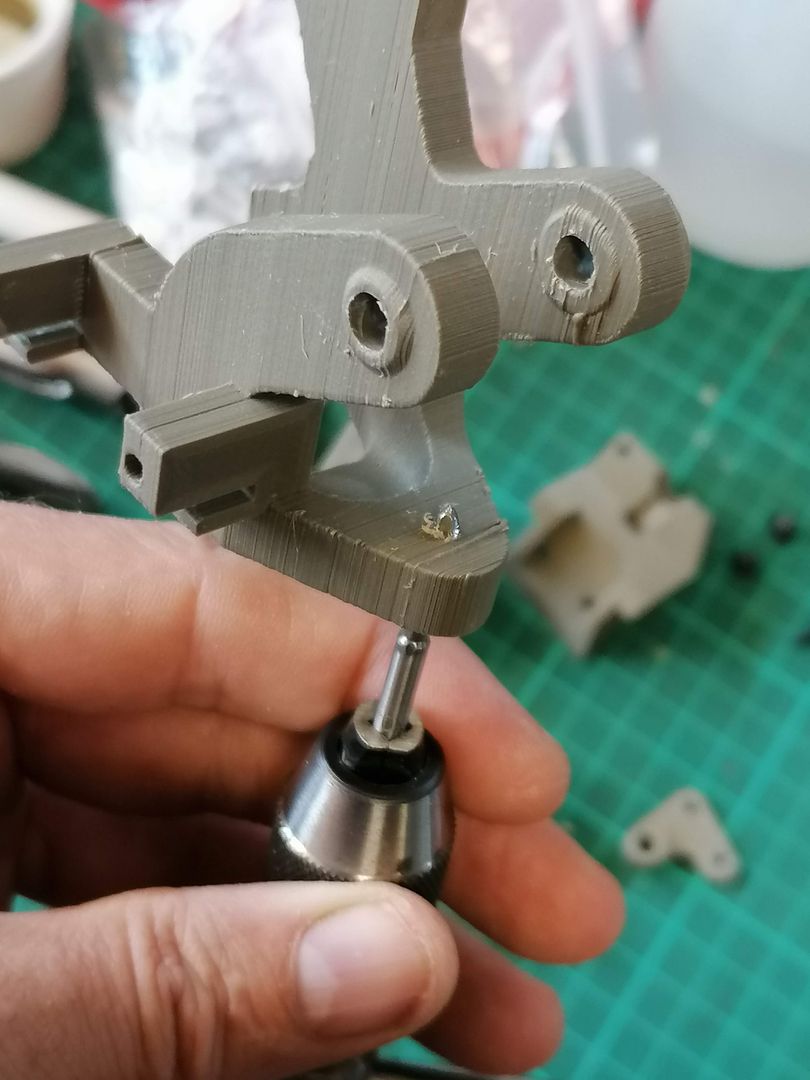

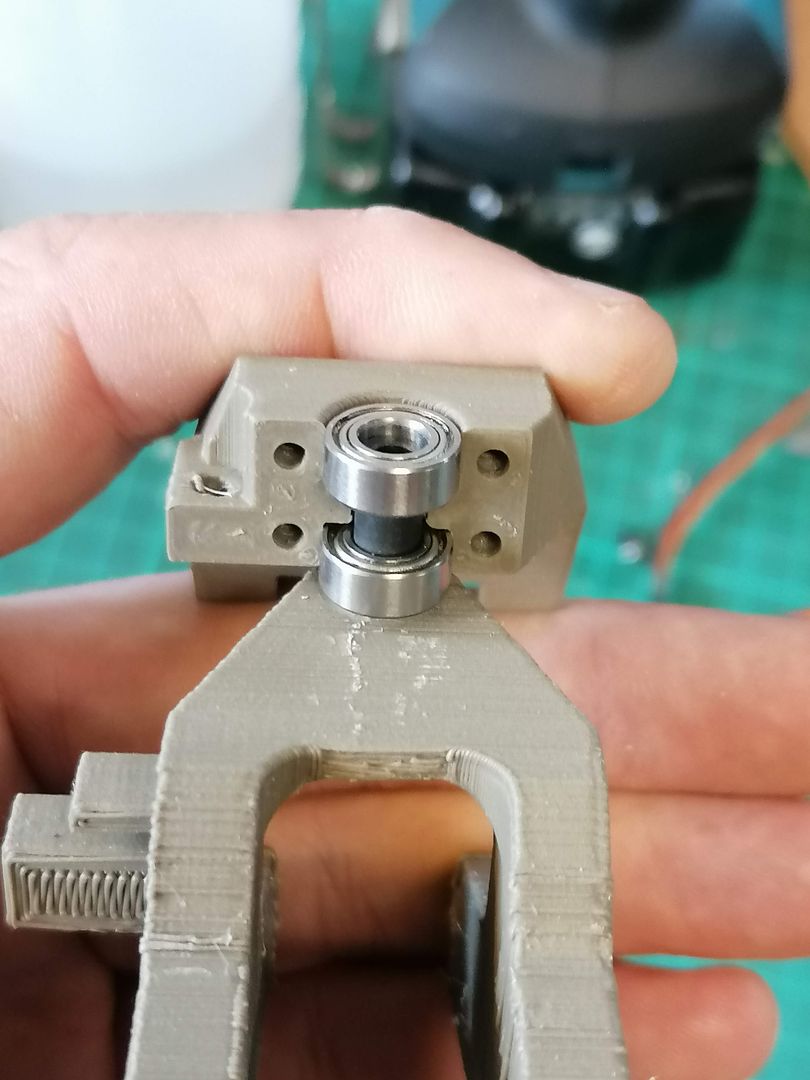

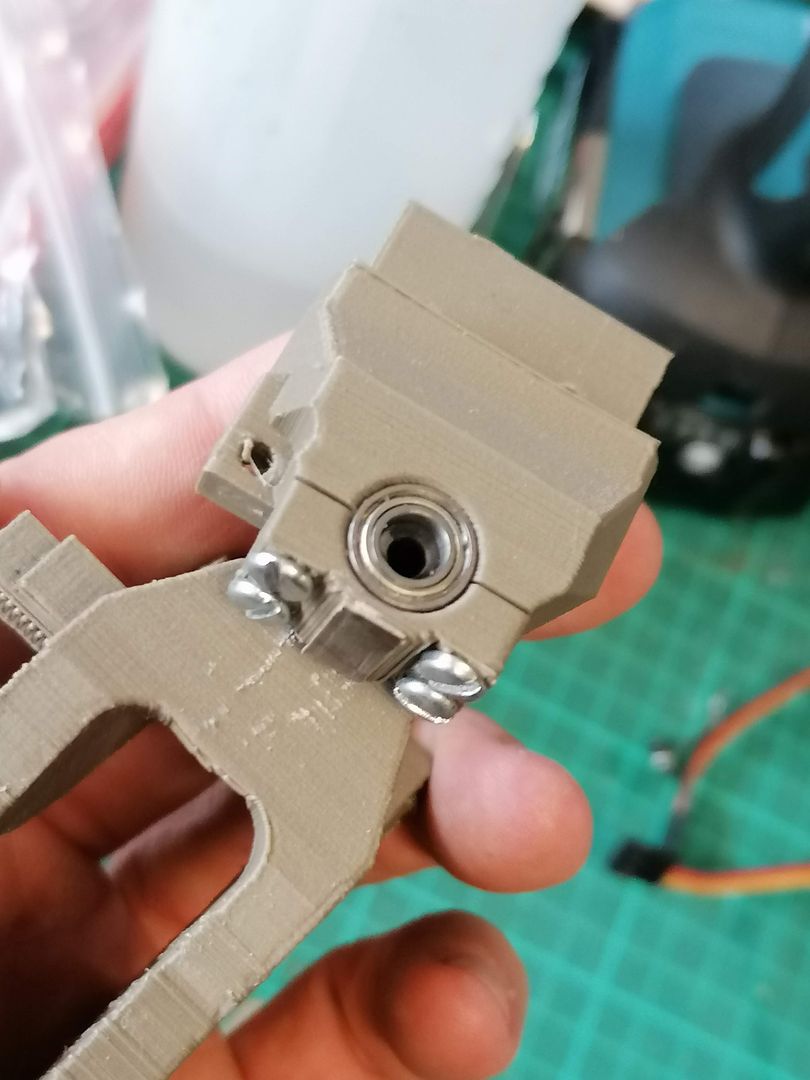

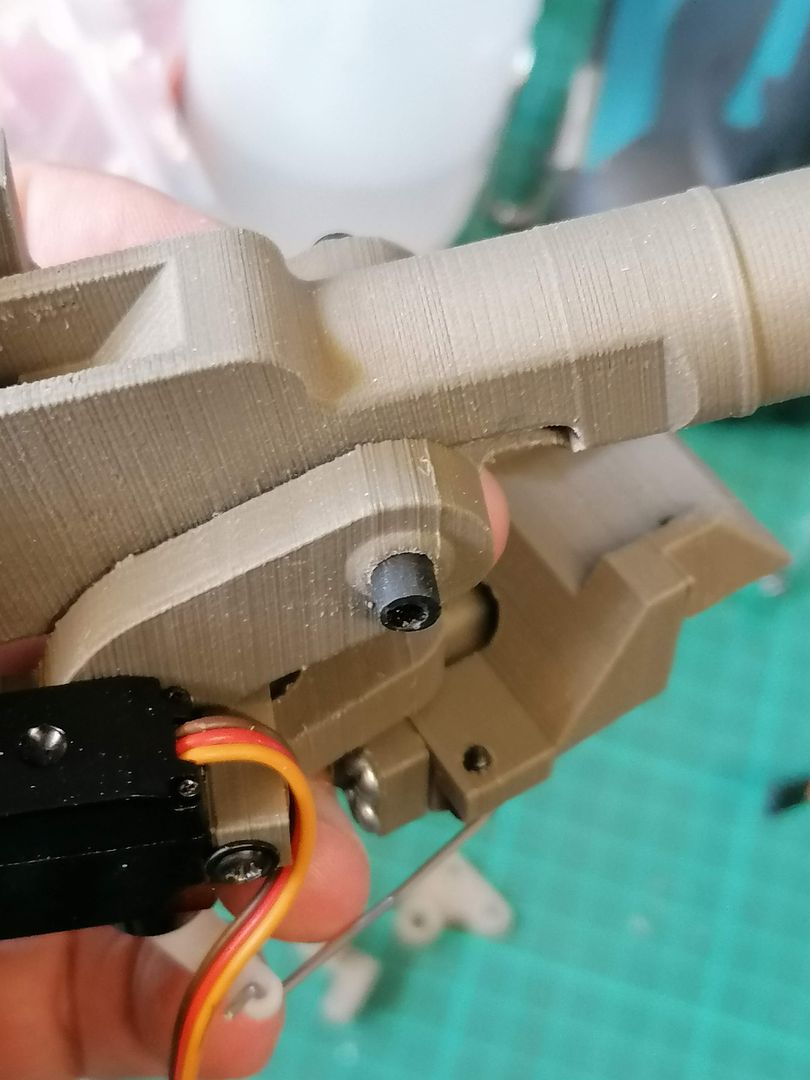

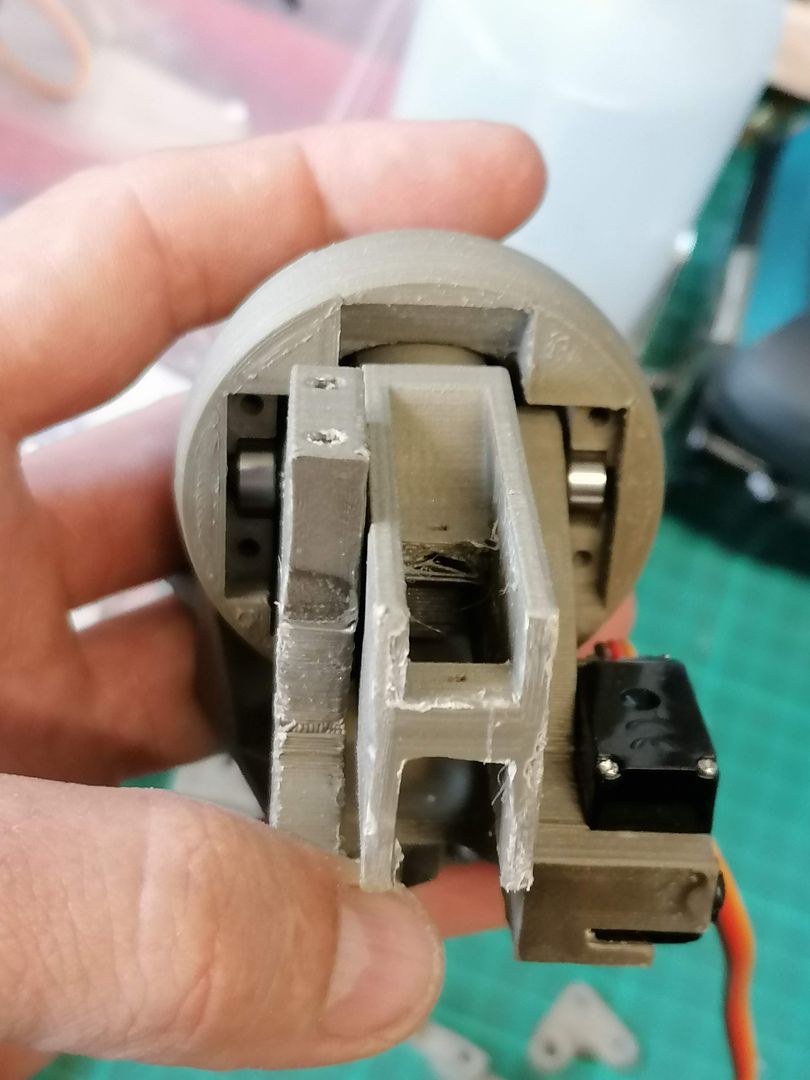

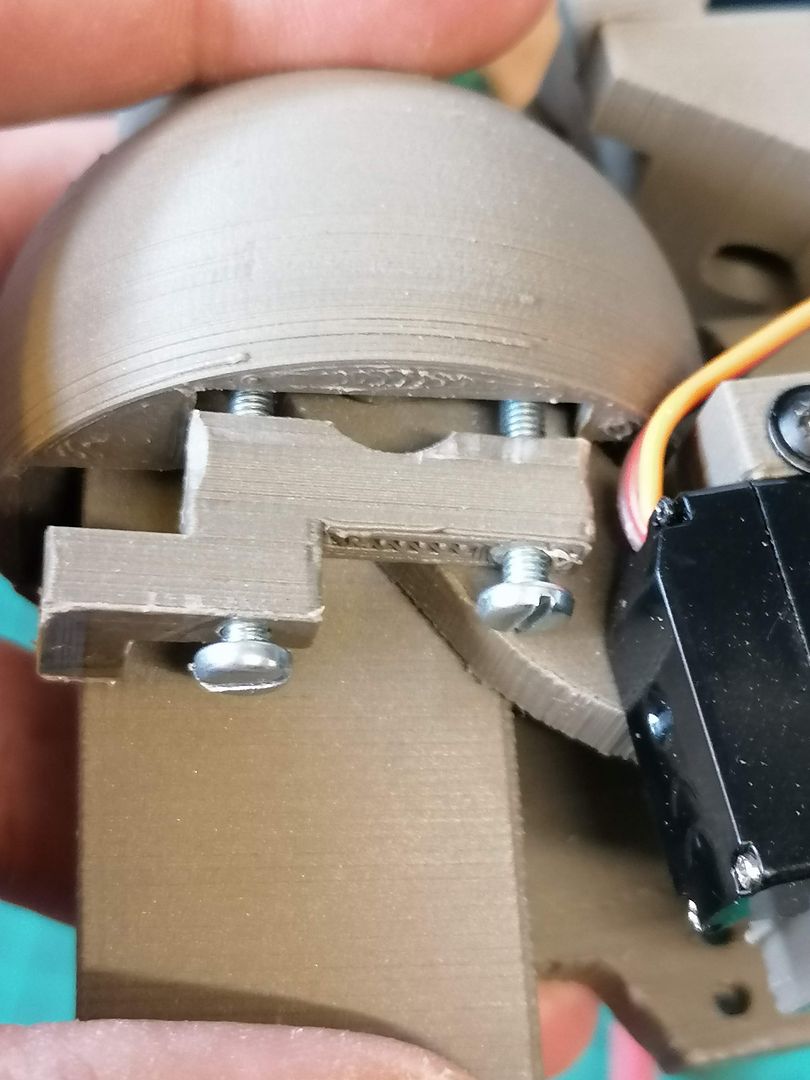

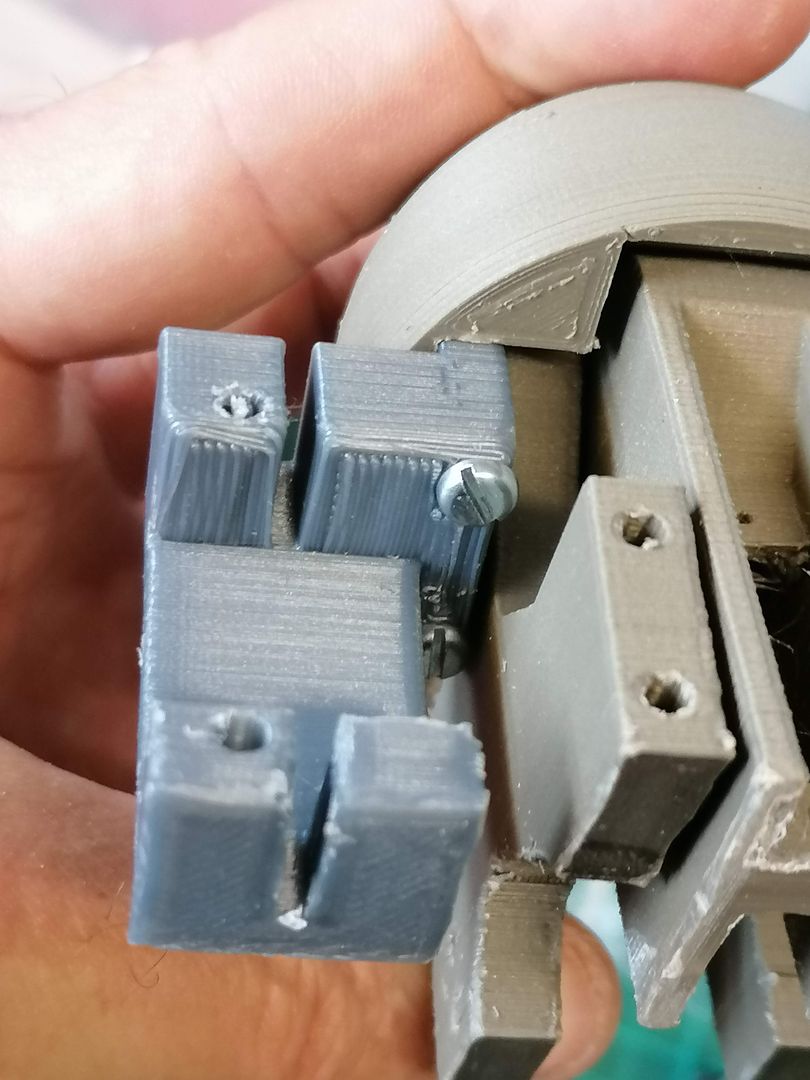

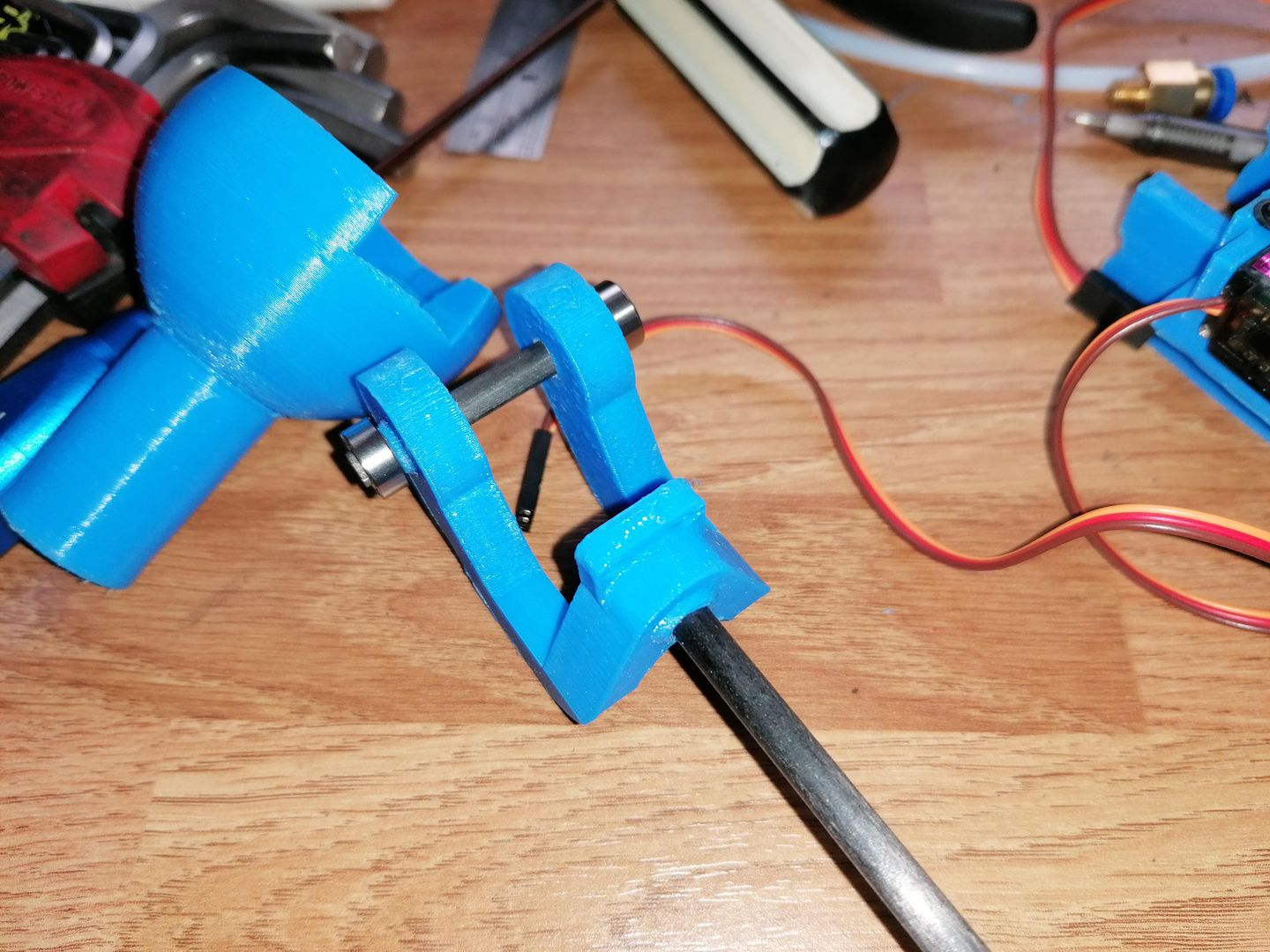

With a while spent on the computer and different configurations I finaly came up with this one compact and with plenty of movement.

Sorry I havnt any pictures of its assembly but I will get some when I make a improved print quality one.

This week the better filament arrived and a new citadel was born (sort of

I have also printed off better roof sections.

I am now working on the hatch covers and small detail parts and will post as I get further along with it.