Scratchbuilders/3D printers, I need your wisdom! DAF YA 126

Posted: Sat May 05, 2018 8:11 pm

How viable would something like this be, on the standard 4x4 HL chassis?

DAF YA 126

Post WWII the Dutch used old hand-me-down Dodge WC-51 as standard light military truck. However, in the 1950s the Dutch government decided to replace those with indigenous designed and built light trucks, and the YA 126 was the result.

The truck was designed and built by DAF. The model number explains exactly what it is and does:

Y = Military vehicle

A = Common type

1 = 1 ton cargo capacity

2 = Second model

6 = 6 rotating wheels.

6 rotating wheels? It's a 4x4 truck! Yes, but the spare wheels are hung freely rotating (though un-driven) and positioned so that if the truck high-centers over a berm, the spare wheels will keep it from getting stuck.

Several variants were built, including an ambulance version:

A command / radio version:

A firefighting version:

And a UN version:

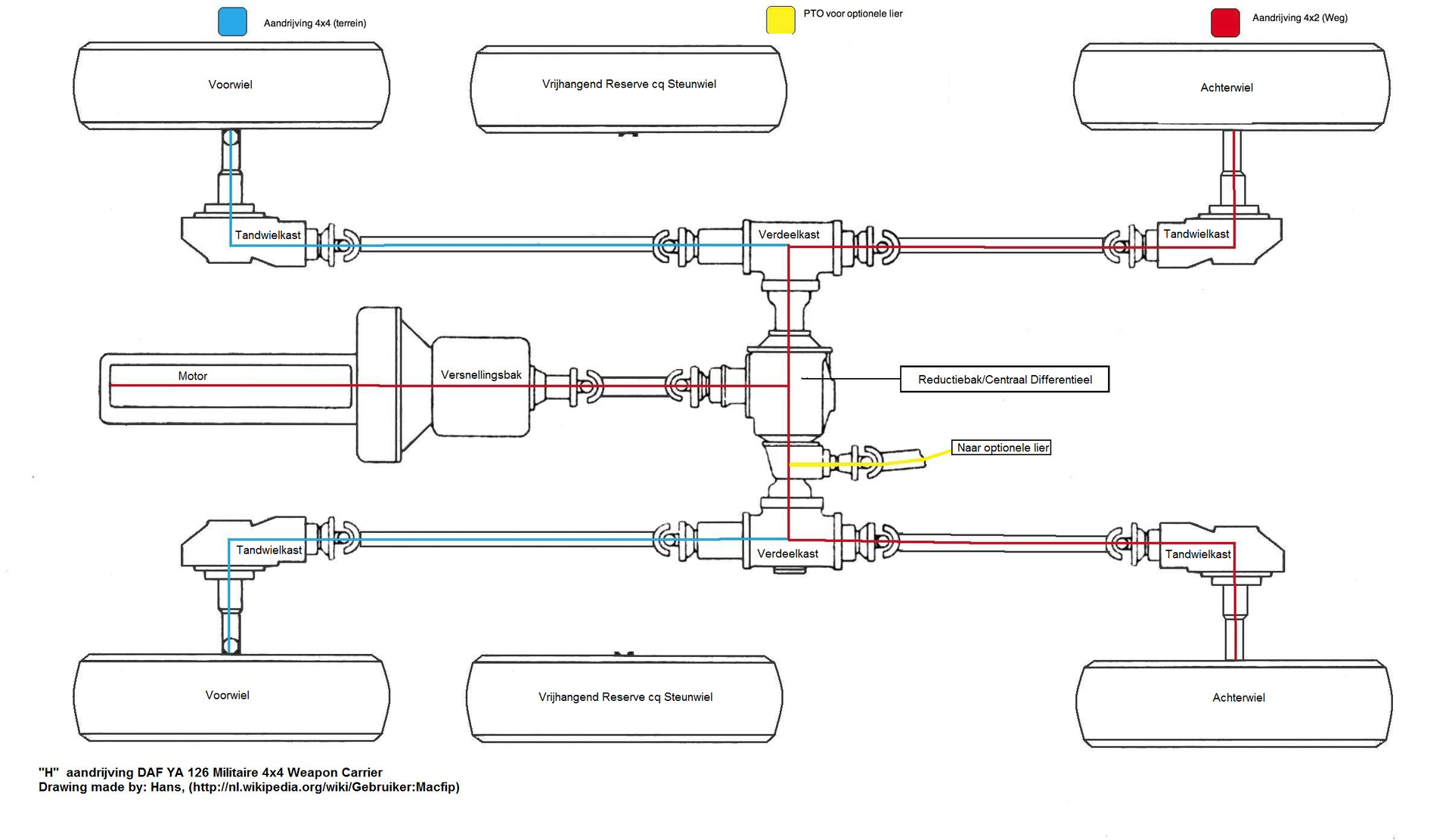

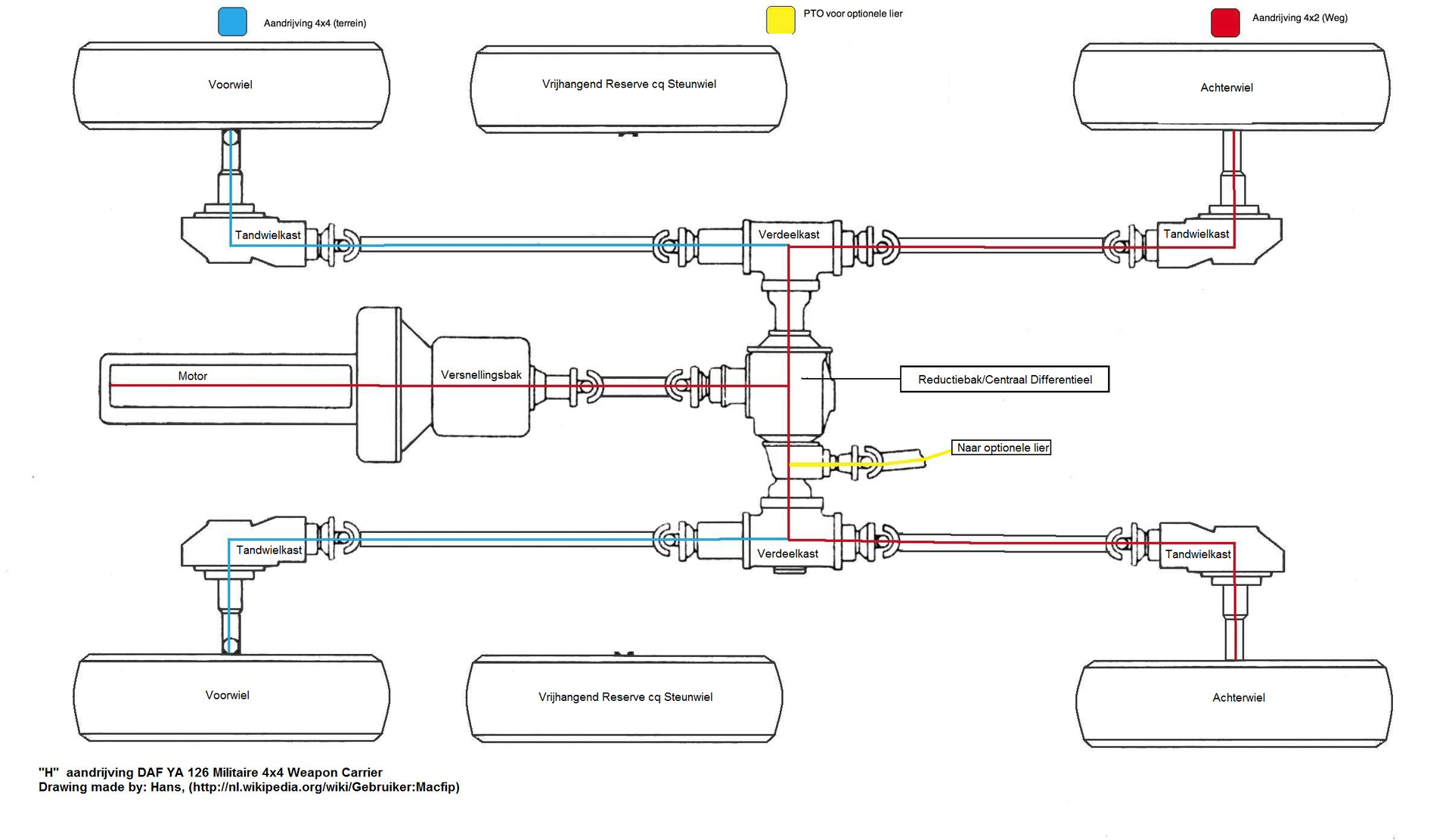

The chassis is a very interesting one, with a so called "H drive", to allow for greater ground clearance between the wheels:

Despite being Dutch designed and built, it used an American engine, a 4.62 liter 6-inline Gasoline engine by Hercules, delivering 102 hp and 285 nm torque, giving the YA 126 a top speed of around 80 kph.

What I'm wondering is, how difficult would it be to scratch build an upper to fit on the HL 4x4 truck chassis, ignoring the H-drive train. I'm a complete noob at these things, wouldn't know how or where to start. I've not even done the math on the chassis, whether the track and wheelbase is close / accurate enough to the real vehicle, but a quick once-over with my Mk i eyeball suggests it's close-ish enough for government work.

If someone were to be willing to do some design work on this I might even be willing to pay them ...

DAF YA 126

Post WWII the Dutch used old hand-me-down Dodge WC-51 as standard light military truck. However, in the 1950s the Dutch government decided to replace those with indigenous designed and built light trucks, and the YA 126 was the result.

The truck was designed and built by DAF. The model number explains exactly what it is and does:

Y = Military vehicle

A = Common type

1 = 1 ton cargo capacity

2 = Second model

6 = 6 rotating wheels.

6 rotating wheels? It's a 4x4 truck! Yes, but the spare wheels are hung freely rotating (though un-driven) and positioned so that if the truck high-centers over a berm, the spare wheels will keep it from getting stuck.

Several variants were built, including an ambulance version:

A command / radio version:

A firefighting version:

And a UN version:

The chassis is a very interesting one, with a so called "H drive", to allow for greater ground clearance between the wheels:

Despite being Dutch designed and built, it used an American engine, a 4.62 liter 6-inline Gasoline engine by Hercules, delivering 102 hp and 285 nm torque, giving the YA 126 a top speed of around 80 kph.

What I'm wondering is, how difficult would it be to scratch build an upper to fit on the HL 4x4 truck chassis, ignoring the H-drive train. I'm a complete noob at these things, wouldn't know how or where to start. I've not even done the math on the chassis, whether the track and wheelbase is close / accurate enough to the real vehicle, but a quick once-over with my Mk i eyeball suggests it's close-ish enough for government work.

If someone were to be willing to do some design work on this I might even be willing to pay them ...