Page 1 of 3

1/10 Abrams - Scratch build project

Posted: Sun Feb 25, 2018 8:16 pm

by Oz Abrams

G’day all and please be patient with me as it’s both the first time I’ve posted on this forum & also the first time I’ve scratch built a tank.

Why 1/10?

For me it’s the Goldilocks size - just right because with big hands, I reckoned anything smaller was too small, anything bigger wouldn’t fit in the car & dividing by 10 is easier maths!

Why an Abrams?

It’s what’s currently in-service in my homeland.

The plan

To build a RC combat capable tank out of plywood with as much scratch build parts as my skills, patience & time allows. I’d like to have a gyro-stabilised gun system firing foam darts (if just at home) or paintballs if I decide to join in the battles.

I’m still to decide on the track system - either hinges or 3D printed track pads/wooden blocks on a conveyor belt.

I’m also to decide on motors but current front runner is drill motors.

So for now, I’ll build the hull then work out the rest.

The plans are drawn, the garage cleared out and Officer Commanding - Home Command has finally given approval for the project.

- The project office

I’m not a frequent forum poster so I’ll come back with an update when I can.

Cheers.

Re: 1/10 Abrams - Scratch build project

Posted: Mon Feb 26, 2018 11:25 am

by Estnische

Hey Oz, welcome to the forum.

When you get a chance, post in the introductions section and tell us about yourself, why RC tanks, where you are etc and your armour likes ( I guess that is Abrams - I spied some camo gear, are you in the service?).

Re: 1/10 Abrams - Scratch build project

Posted: Sun Mar 18, 2018 5:27 pm

by Oz Abrams

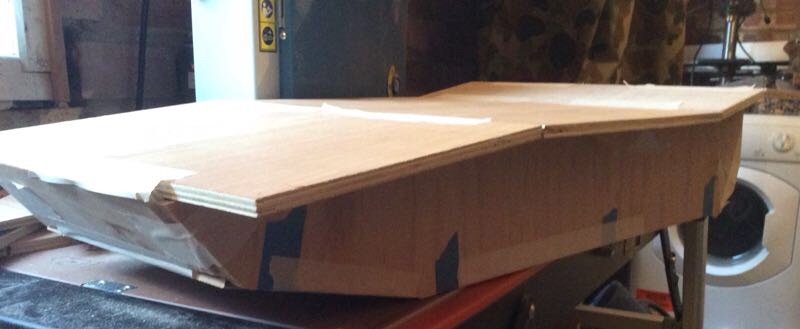

So, after a disastrous start due to a wilful jigsaw I had to start again after buying myself a bandsaw. Then man-flu, snow & work put me back a bit but I’ve now got the Hull form and the photos show it mocked up.

I will work on the detail to get the angles right so the joints are snug.

Next decision is what suspension to use. I’d appreciate some advice on that. Should I go for:

- Spring tensioned trailing arm, or

Spring tensioned, vertical slots in which the axles move vertically

I’m also starting to think about motor and drive gear. My current preference is to buy a couple of 18v rechargeable drills and strip the motors out of them. A bit of fiddling to lock the gearbox but I was thinking of Mounting them 90deg to the drive axle with a single gear.

Anyway, that’s it for now.

- 8CE30510-6398-483A-87C7-CA640BDEC15F.jpeg (49.98 KiB) Viewed 6403 times

- E833F95A-6ECB-4055-80FF-DA2E620BAF26.jpeg (55.79 KiB) Viewed 6402 times

PS - We’ll spotted. Some auscam gear from a former life. Mind you, my tanks were full of fuel,

Re: 1/10 Abrams - Scratch build project

Posted: Tue Aug 14, 2018 5:29 pm

by Oz Abrams

Hi everyone - as I said in my first post, I'm not good at social media forums so apologies for the lack of updates.

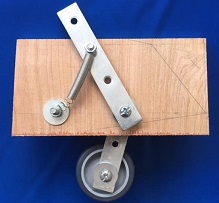

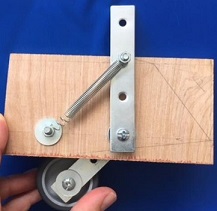

I've been struggling to get build time so I haven't progressed far with the structural build of the hull. I have had some time to try & work out suspension which I built a prototype for and hope to transfer to the hull soon.

But I'm a little stuck on the wheels & axles and don't want to install trailing arm suspension or make the torsion bars until I have the right axle size sorted out.

Can you help out?

I'm thinking of fixing M6 diameter bolts through a swing arm inside the hull, through a 6mm hole in the hull & fixed to a wooden torsion bar. The swing arm would be held upright by spring tension. Hopefully the photos below post OK.

- Suspension - extended.jpg (33.13 KiB) Viewed 6245 times

- Suspension - weight on.jpg (33.35 KiB) Viewed 6245 times

So now, I'm planning to cut the 58mm diameter wheels from 9mm thick marine ply glued together to get the right depth.

But should I fix the axle to the...

(a) wheel and have it rotate at the torsion end, or

(b) torsion arm and have the wheel rotate around it?

Should I use a bearing for the bolt/axle or would a simple sleeve/tube through the wood be sufficient to allow the bolt to rotate?

Thanks in advance,

Oz

Re: 1/10 Abrams - Scratch build project

Posted: Tue Aug 14, 2018 7:11 pm

by Aljones34

Welcome Oz, great plan and from the start photos much more skill than I have. I need a machine to produce a base model in plastic first. Looking forward to following your build.

Re: 1/10 Abrams - Scratch build project

Posted: Wed Aug 15, 2018 2:26 pm

by Oz Abrams

Thanks but was talking about the road wheels. I haven't decided on the track system yet but probably going with pop-riveted hinges.

Re: 1/10 Abrams - Scratch build project

Posted: Thu Dec 20, 2018 6:53 pm

by Oz Abrams

OK, it’s been a while but work & family commitments meant Ive been on the go slow.

For those observant readers, the reason some of the road wheels edges are black is because the hole saw burnt them - I managed to blunt 3 hole saws doing the wheels - and the friction built up as I drilled. Probably should have paid more initially for a decent one!!

Next step is to fit the road wheels to the hull to test the full rig. Then the tracks.

- PNG image 2.png (147.37 KiB) Viewed 5852 times

- PNG image 4.png (136.64 KiB) Viewed 5852 times

- PNG image 3.png (171.1 KiB) Viewed 5852 times

Oz

Re: 1/10 Abrams - Scratch build project

Posted: Thu Dec 20, 2018 9:21 pm

by HERMAN BIX

Coming on strong now mate.

Just a thought, check the availability of Rubber tube that might fit right over those wheels and perhaps slice sections off & secure them over as tyres to give more authentic look.

Bicycle tube maybe ?

As for the wheels rotation, I would go with the theory that make the easiest part to manufacture or replace the wearing one if necessary

That way you only face repairs or replacement of simpler-sacrificial parts.

Re: 1/10 Abrams - Scratch build project

Posted: Sat Dec 22, 2018 9:48 pm

by Oz Abrams

Nice idea - I’ll have a look for the rubber tubes.

I’ve gone with brass tubing in the wheel hubs to rotate around 5mm bolts. As you say, easy to take off and maintain/replace.

Any recommendations on track systems? I can’t decide between the hinge system or a belt with wooden blocks attached.

Re: 1/10 Abrams - Scratch build project

Posted: Sat Dec 22, 2018 10:42 pm

by HERMAN BIX

For tracks again, the best components to replace or repair.

Leaning toward a belt as it won’t be as destructive on the running gear.

Perhaps a small section vee belt with small screws thru a tooth//timing belt turned inside out so it’s terth act as track treads?

That way the small vee section can act as guide horns, can cut small sections out or ever use a notched vee belt if you can find the right size.