Page 1 of 2

Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 11:17 am

by Blackadder123

Hi,

Has anyone ever tried to pour resin into the lower hull in order to stiffen it after removing the battery box? I've never tried anything with resin so I'm really not sure which type of resin would best fit this purpose. I'm guessing that it needs to be of a high hardness type as anything flexible would defeat its purpose - Any keywords I should be looking out for? As for the hardening agent, is there a rule on what ratios to mix the two? And is there a danger of resin damaging the plastic?

Thanks

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 12:24 pm

by 43rdRecceReg

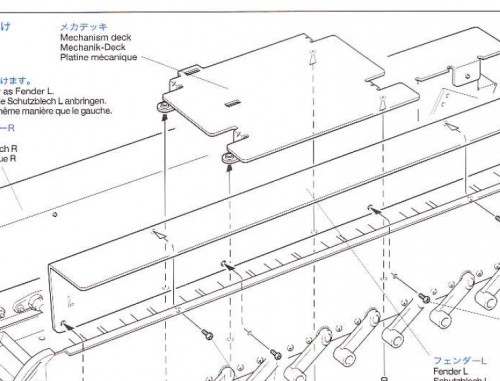

That could make for a messy interior. Bonding in a sheet of aluminium alloy, with epoxy, would make it easier to use the space to add a larger MFU, or speaker...and so on. Here's Tamiya's 'mechanism deck. It has the effect of adding torsional rigidity to the chassis, but also serves as the space where the MFU (DMD) or Electronic controller is attached.

- Tamiya's 'mechanism deck'

Sheets of alloy for modelling, in a variety of sizes, are readily available from model shops online. Epoxy or nuts and screws will make for a solid attachment.

Other than that, flats of 2 or 3 mm styrene could be bonded in, along with right angle bracing struts/ bulkheads. Again, supportive structural styrene (Right angle, Cubed, Tubular etc..) is readily available on the Net. Here's just one outlet, for example:

http://www.cornwallmodelboats.co.uk/aca ... icard.html

You'll find many examples of structural reinforcement posted in the Archives here.

What type of tank is it for anyway? Some have more rigid shells than others...

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 12:32 pm

by RobW

On the HL Sherman I found that putting a good bulkhead in behind the motors really stiffened up the hull after removing the battery box. On the T34 I'm thinking I'll need a strip across the front too.

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 1:11 pm

by Ludwig von wigbearer

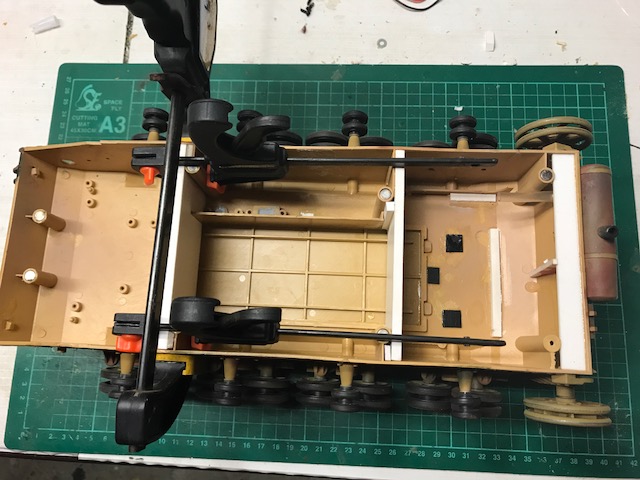

- P1040466.JPG (98.33 KiB) Viewed 1999 times

Heres what I did with my mato Sherman, once the box had been cut out I cut a bulkhead and floor out of some upvc

its about 6mm stuck the floor down with a product called sticks like sh$t, ( that's its proper name) and araldited and

screwed the bulkhead behind the motors, its very strong

regards john.

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 1:18 pm

by Afrikakorps

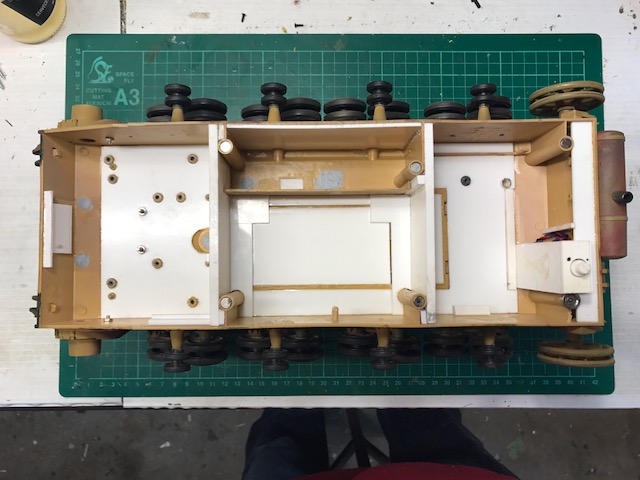

On the panzer iv hull I used 2mm styrene epoxied to the hull floor and side wall, and 5mm as a brace between the side walls. Its good and solid now !

Cheers

AK

- IMG_2007.JPG (95.13 KiB) Viewed 1995 times

- IMG_2013.JPG (80.86 KiB) Viewed 1995 times

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 2:10 pm

by BarryC

Your idea would work however..... should for any reason the hull not be perfectly squared and level or if the heat of the curing process cause the resin or hull to twist then you will be in a very bad way.

All the ideas others have shown are a MUCH better solutions!

Below is the link to my Abrams build and somewhere around page 5 or 6 begins the process of strengthening the hull. It is basically what others have shown, floor doublers and bulkheads. It is solid and has very little flex regardless of the added lead weight.

Barry

viewtopic.php?f=201&t=18880

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 2:45 pm

by dgsselkirk

My 2 cents....

Been using resin in all my lower hulls for 5 years no issues. It's all I use if doing an HL lower. With the bulkheads it totally eliminates any hull flex.

I gut the battery box out and do a fill about 1/4" to 3/8" depending on the tank. I still also put a bulkhead behind the motors and usually one at the back somewhere on top of the resin. I like 1 to 1 resins. You can find lots of different ones at an art store they usually carry them. I buy like a litre and it is good for about 4 tanks. I also, depending on the tank, will put metal weights in the resin to balance out the gearboxes and motors (I usually upgrade to heavier). I find this really helps with the jerk starts and just the overall ride of the tank.

I use wheel balancing leads from my mechanic by the bucket and use the stove to melt them down. (Don't tell my wife)

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 2:58 pm

by BarryC

dgsselkirk wrote:My 2 cents....

Been using resin in all my lower hulls for 5 years no issues. It's all I use if doing an HL lower. With the bulkheads it totally eliminates any hull flex.

I gut the battery box out and do a fill about 1/4" to 3/8" depending on the tank. I still also put a bulkhead behind the motors and usually one at the back somewhere on top of the resin. I like 1 to 1 resins. You can find lots of different ones at an art store they usually carry them. I buy like a litre and it is good for about 4 tanks. I also, depending on the tank, will put metal weights in the resin to balance out the gearboxes and motors (I usually upgrade to heavier). I find this really helps with the jerk starts and just the overall ride of the tank.

I use wheel balancing leads from my mechanic by the bucket and use the stove to melt them down. (Don't tell my wife)

The voice of far more experience than I have!

Barry

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 6:28 pm

by Blackadder123

dgsselkirk wrote:My 2 cents....

Been using resin in all my lower hulls for 5 years no issues. It's all I use if doing an HL lower. With the bulkheads it totally eliminates any hull flex.

I gut the battery box out and do a fill about 1/4" to 3/8" depending on the tank. I still also put a bulkhead behind the motors and usually one at the back somewhere on top of the resin. I like 1 to 1 resins. You can find lots of different ones at an art store they usually carry them. I buy like a litre and it is good for about 4 tanks. I also, depending on the tank, will put metal weights in the resin to balance out the gearboxes and motors (I usually upgrade to heavier). I find this really helps with the jerk starts and just the overall ride of the tank.

I use wheel balancing leads from my mechanic by the bucket and use the stove to melt them down. (Don't tell my wife)

How do you decide the depth of resin based on tank? How deep of a resin would you recommend on a Pershing? Also, the bulkheads at the front and back of the resin cast have to be waterproof, right? Any trick you use to seal up the two bulkheads?

Would those silicone sealants be a good shout?

Re: Resin cast to stiffen hull?

Posted: Tue Sep 12, 2017 7:25 pm

by dgsselkirk

I actually just finished up a Pershing for the club draw. I would go 3/8" since the Pershing is a fairly wide tank. For the bulkheads I glue them in position using crazy glue and then 2 part epoxy on the bottom edges to give them strength and seal them to the resin. I get the 2 part epoxy at my local dollar store and it works great. Now, I did not set out to make it waterproof at all so I would have to look at it a little closer with some suggestions if that is what you are after. I will take some pics tonight if you like....