Time for another update sooner than I'd expected! Still no sign of the grill so not got new pics of the build today but I do have some images of my other delivery which is AWESOME by the way! The shipping on this stuff was horrendous but the joy of going through it all is like Xmas at Easter so it was worth it I guess!

Anyway I managed to find a guy with a whole bunch of tracks, wheels, gearboxes, you name it, but sadly right on the other side of the world... As I said, it's been crazy expensive but serious value for money (if only I had more of the latter, haven't even paid for these parts yet :s) Here is the haul I just signed for this morning and it's seriously a hell of a lot more than I was expecting! Prepare to be amazed at my new collection...

Big box! Though there's nothing here to compare it to so you have to take my word for it. You'll soon see how much was in it anyway

First thing to come out of it was a bunch of drive wheels, 8 of them to be precise! They're all metal which I wasn't expecting so they're heavier than I'd thought they would be but look very nice nonetheless! I later found another roll of these so I now have 18 matching drive wheels! That's 4 per track but it does at least give me more freedom on where to introduce the final drive to the track.

Now here's a massive pile of electronics, most of which I wasn't expecting and nearly all of which I can't describe! I believe there is smoke and sound there along with 4 gearboxes and some other bits and bobs. Please look at the images and tell me if you can make it out!

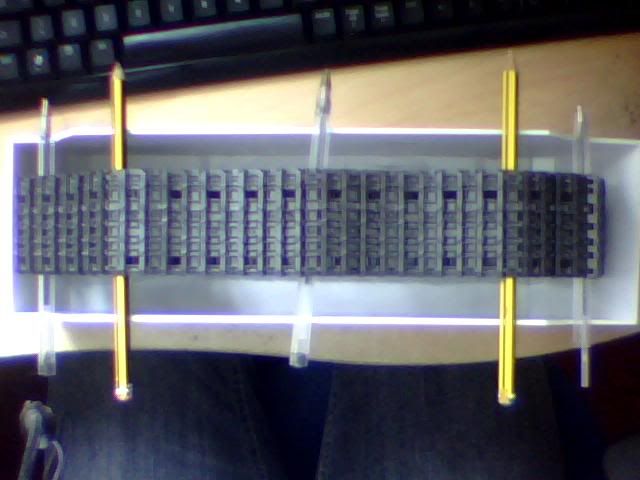

Here's one set pretty straightened out;

And a shot of a Heng Long bit that I now have 2 of in the other bundle;

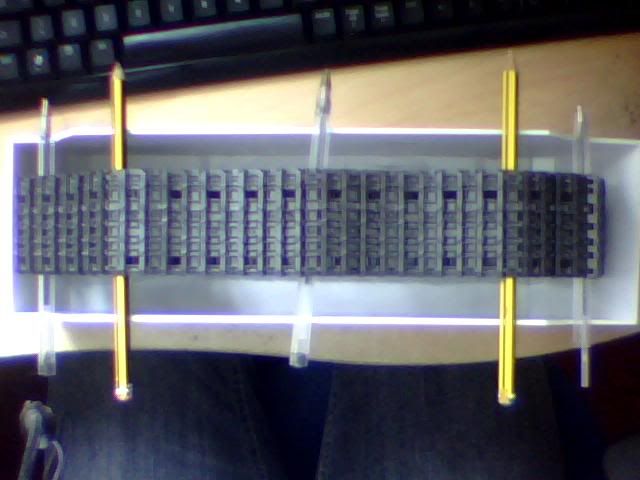

Here's where it gets crazy mad though... I always said that making this project RC was my ultimate goal but either way it would need tracks. Here they are...

I now have 8 of these tracks which I believe are from a King Tiger? Here is one next to my puny normal Tiger track...

I wanted to give an idea of just how much track I now have so I laid it end to end and it reaches from the sitting room right through to the kitchen! I also have 2 bags of individual track segments and another bag of spare pins!

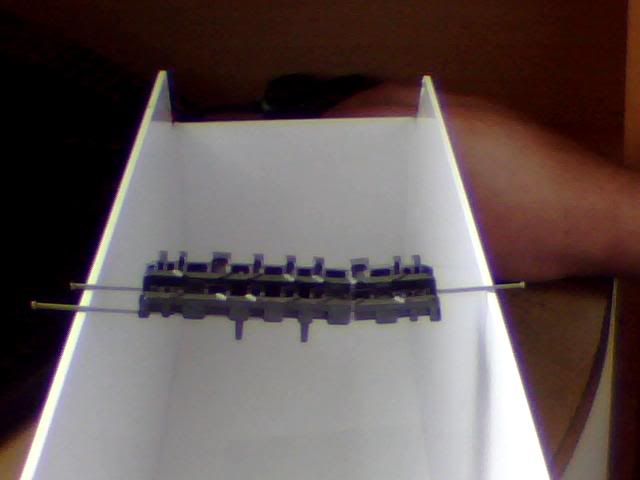

I already knew this was about 50mm wide track so I was absolutely certain it would look to narrow on the Mammoth but I took a look anyway. This is a single track from the King and it's about 40mm short of filling the full width of the armour.

I then laid another one half over it to show what I think looks like a good width. It's about 70-75mm and the space is just shy of 90mm wide.

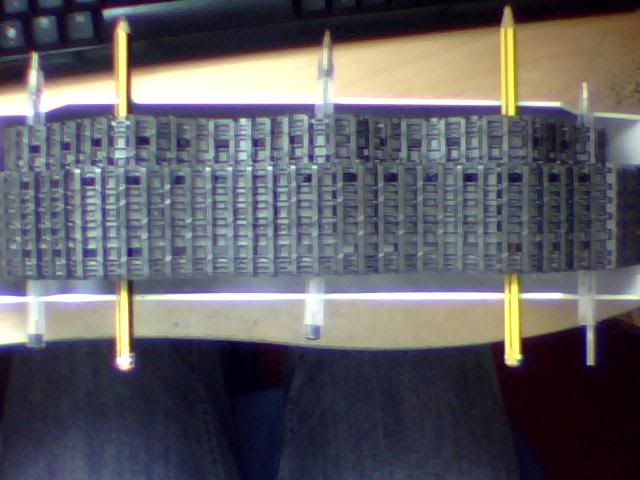

So I've been sitting pondering what to do with this stuff and playing with some of the spare links to see what would be involved in widening the track. As it turns out, quite a lot! I figured out that each 73cm length comprises of 296 separate links. Now obviously to widen each piece I'll need two sections to make one, giving a total of almost 600 links per track. Over four tracks that would mean sitting down and nodifying almost 2,400 links to make the tracks as wide as I would like them!

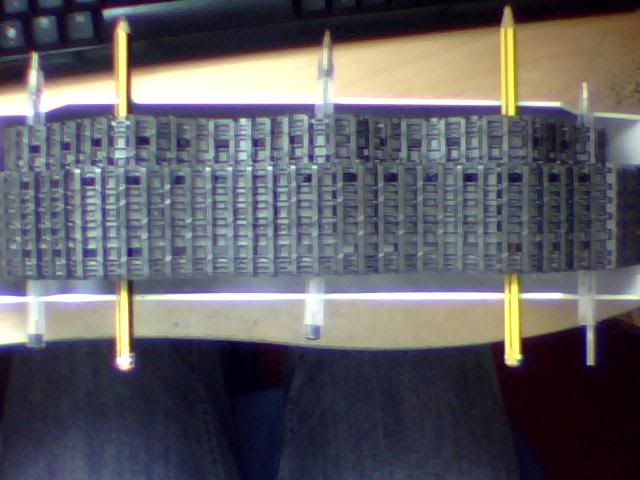

Now I already know I have well over that as each of the 8 complete tracks I have is about 18 links longer than they need to be for the Mammoth but do I really want to spend that much time adding a mere 15mm to my track widths? Well... No... But I do want this to look right and it's going to need wider tracks for that to be true. So I've been experimenting and I came up with the below result as an initial prototype.

This is a fairly quick try at a very early solution and is still a bit narrow for my liking at just 67mm. The below image shows how it would look in place and I reckon there's at least another 8-10 mm to be had out of that.

Of course, I've already stumbled upon how difficult this would be and there are many more problems than just the obvious ones of time and labour. Of course strength is going to be an issue as essentially I'm just sticking an extra bit of track on the end of the original (though it's not that simple, I'm actually cutting one end off 2 pieces then joining them seamlessly in the middle) The pins are now ALL too short so I'd need to cut almost 300 new ones from the right gauge of wire, although next to 2,400 links that doesn't sound like too big a job!

The upside of needing the new pins is that the links would regain a lot of their strength once these are in place. It would ensure that there is no twisting or bending of the links and so help preserve the artificial join. Anotehr problem though is that I'll be left with a massive overhang of track on either the inside or outside of the drive wheel. These are approximately 35mm wide and if they were fitted with 70mm track there would be almost 25mm of new track that was basically attached to one side of the original piece.

Another problem which is purely cosmetic does result in the introduction of a third hole in each link (apologies if there's an official name!) This is obviously caused by the additional track being made from pieces that already have the holes in but it looks a bit crappy as it's clearly unnecessary so why is it there?

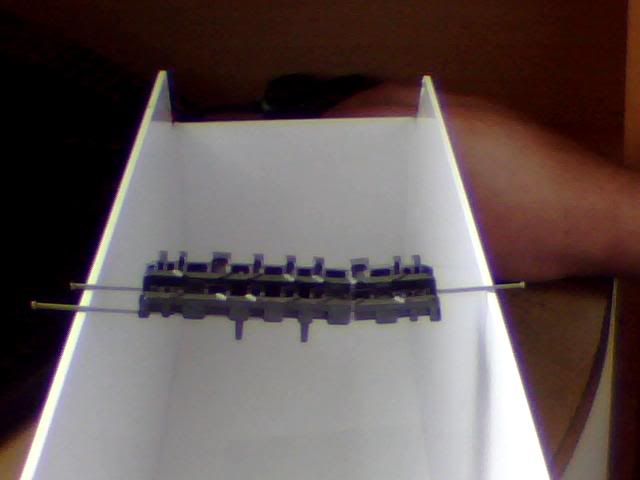

Thankfully... Writing this last piece has just given me a mini brainwave... What if that third hole was being used? Remember me saying I have twice as many drive wheels as I need? And I wanted the track about 70-75mm wide? Problem solved...

I think it may work with the right attention given to it. The narrow shaft between the outer rims would need widening to at least the diameter of the inner face there (with the bolts on) or it looks way too girlie to work in a real-life situation, other than that though it may have legs. Total track width is almost bang on 75 mm and it would help keep some strength in the construction by having that outer rim for support and a longer wire with the join more towards the centre of each link.

I may have a play later and try making up a few links for that setup, see how it looks/if it works! Let me know what you think, and don't worry I know it's very wierd so I'm not expecting anyone to tell me it's beautiful :p If there are any other ideas as to how I can make this work please let me know

EDIT : Turns out by using this method I can stagger the cuts every other link which will further improve rigidity. These links have male and female links as opposed to uniform ones so I can set the joins in different places on each type which might be nice

AND AGAIN : Made up a few links and it looks pretty good. It'll never be prefect though and will of course take me a million years to do the whole thing like this... So that begs the question, what do we know about molding parts? Any small companies in the world who could make me up 2 molds and crank out a few hundred of these puppies? Or better yet is there a way I can do it myself?