Page 8 of 18

Re: [Support] M25 Dragon Wagon

Posted: Fri Dec 27, 2024 11:21 am

by MonsieurTox

Ecam wrote: ↑Thu Dec 26, 2024 10:48 pm

Just for fun...

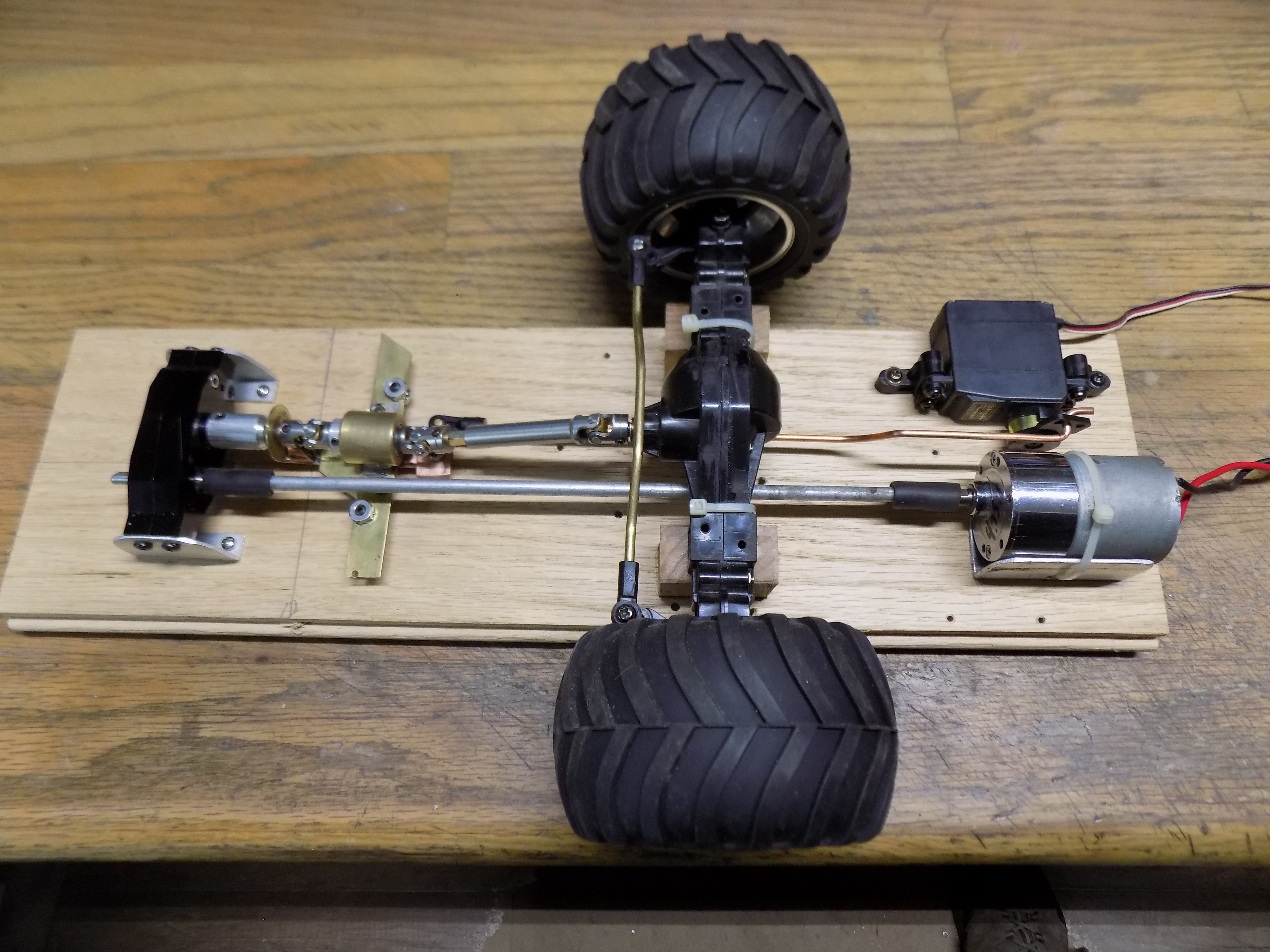

Why do we do this hobby? To enjoy ourselves. First test of a front axle disconnect. The pillow block will not be used (white styrene part). Instead the drive shaft will run from the brass piece to the diff. I can possibly shorten it up by an inch (25mm) if needed.

Awesome Eric ! That's what I wanted to do for the propeller shaft of my DUKW but changed my mind and decided it woould be too complex and then give its own motor. But now I see this...

Re: [Support] M25 Dragon Wagon

Posted: Fri Dec 27, 2024 1:52 pm

by Ecam

Re: [Support] M25 Dragon Wagon

Posted: Fri Dec 27, 2024 2:57 pm

by MonsieurTox

Thanks Eric, that is the eaxact same transfer case I have installed in my DUKW ! So I still have the option to use one of the shaft if I copy your disconnecting shaft system ! (makes me think I've never posted pics of it)

Re: [Support] M25 Dragon Wagon

Posted: Fri Dec 27, 2024 5:20 pm

by Ecam

Copy away, pretty simple. I used a brass shaft and brass sheet so I could solder them together. The set (grub) screws that hold the adaptor to the T-case are short, the one that engages the notch is a little longer.

The square shanked setup is one of the 5 driveshafts I ordered when I first started the DUKWs.

Re: [Support] M25 Dragon Wagon

Posted: Sat Dec 28, 2024 7:46 am

by MonsieurTox

Thanks for the explanations Eric, that's genius !

I have a question, the part of the universal joint (the one with the square hole) that goes through the brass tube : how does it turn ? It seems to be an aluminium bushing but is there any ball bearings inside the brass tube ? I guess so because it would turn that well if there was only aluminium as it's kind of gummy.

Re: [Support] M25 Dragon Wagon

Posted: Sat Dec 28, 2024 2:54 pm

by Ecam

Frankly dumb luck digging through the parts and tools. Bearings are 8mm ID and 12mm OD (no idea where they came from...). I don't have a metric set of drill bits yet but found a step drill that had a cutter just shy @ 11.87mm. Used the edge of a box cutter blade to cut the landing to accept the 12mm bearing and the steps made a great backstop for the bearings. Made a collar of aluminum (hint - drill and tap, then do the cutting). The brass bar used to be a punch/drift out in the garage, but in the past couple years it has been getting used in the tank shop (these days about half the length it used to be).

Re: [Support] M25 Dragon Wagon

Posted: Sat Dec 28, 2024 6:09 pm

by MonsieurTox

That's what I thought ! It makes sense ! Thanks, Eric.

Re: [Support] M25 Dragon Wagon

Posted: Sat Dec 28, 2024 8:30 pm

by Ecam

Re: [Support] M25 Dragon Wagon

Posted: Sun Dec 29, 2024 8:28 pm

by Ecam

Last picture and video of the front axle disconnect. Servo is not powered here (finger push).

- 38.JPG (2.37 MiB) Viewed 34 times

Re: [Support] M25 Dragon Wagon

Posted: Sun Dec 29, 2024 9:27 pm

by HERMAN BIX

I want the Kool-aid you've been on mate !!

Very well thought out and executed.