Page 8 of 69

Re: The 3D Printer Thread

Posted: Wed Apr 15, 2015 12:58 pm

by AlwynTurner

Just had an e-mail from hobbyking trumpeting the Turnigy 3d printer at £305

!

http://hobbyking.com/hobbyking/store/__ ... source=EDM

No idea what it's like but the cost of 3d printing kit is almost reaching christmas present list range, especially after seeing what Woz and Rob are producing. Hmm.... perhaps some indoctrination/persuasion/hypnosis/whatever of family members is called for.

Alwyn

Re: The 3D Printer Thread

Posted: Sun Apr 19, 2015 12:43 pm

by Woz

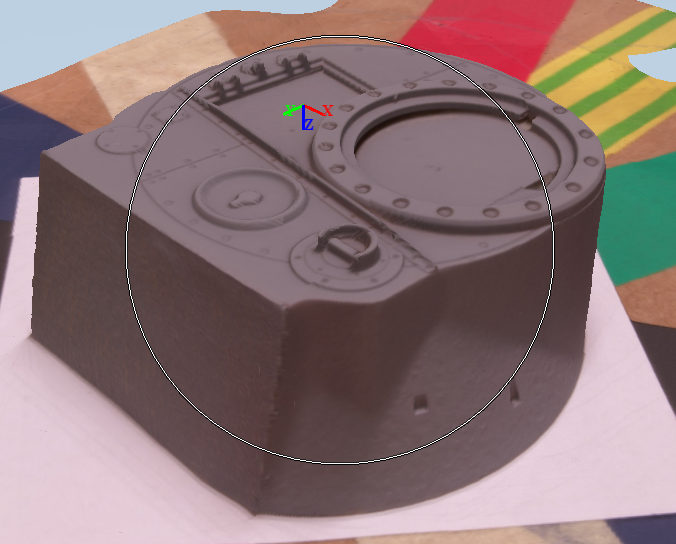

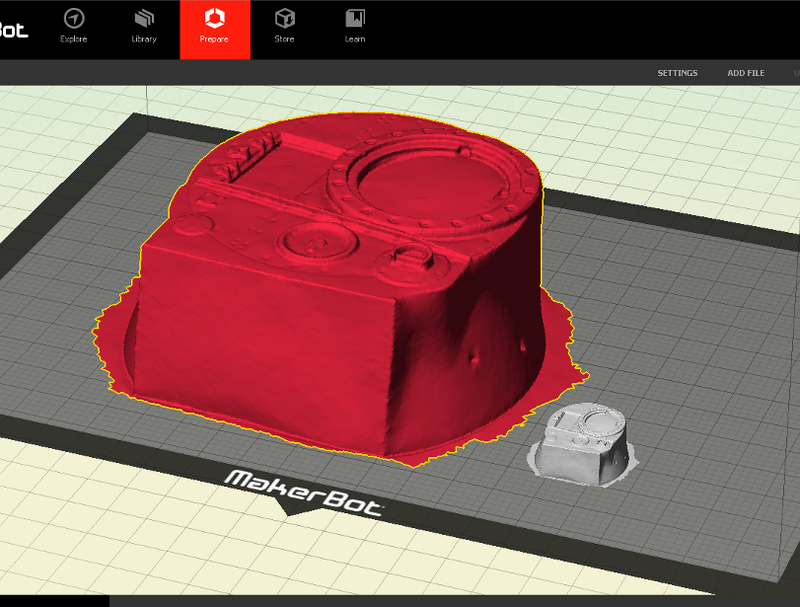

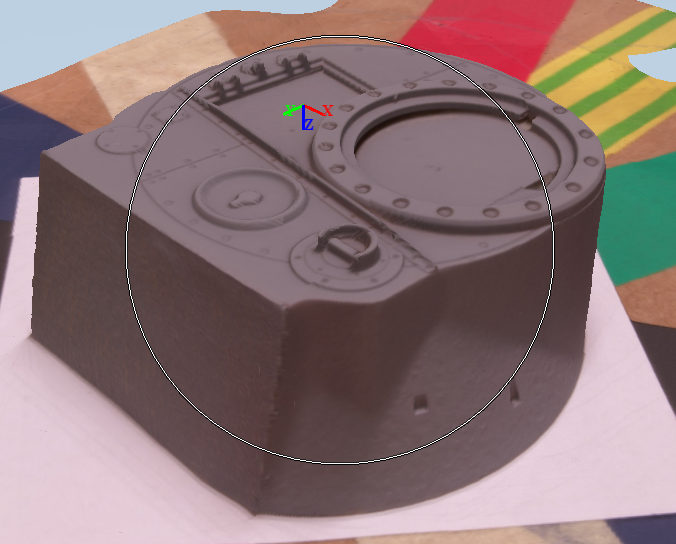

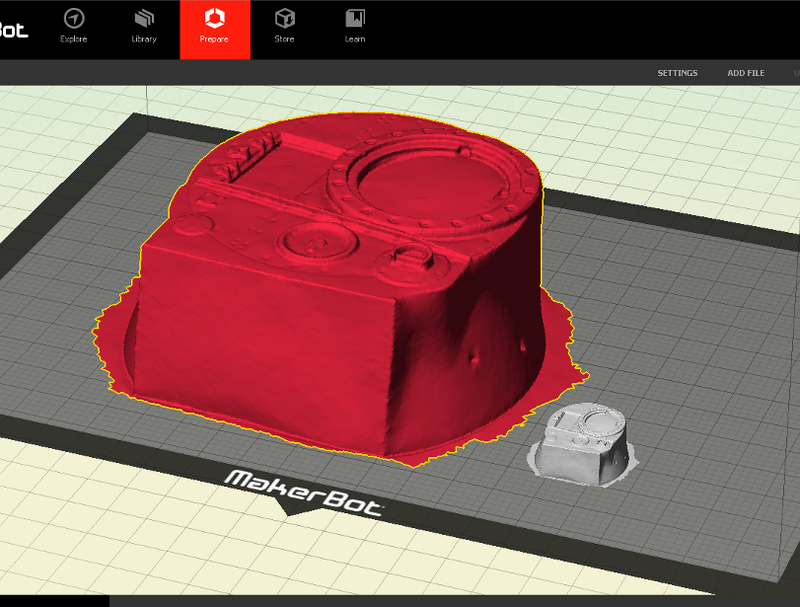

Smaller object and better pics-

Even though the 3D model is pretty small (in white) it can be rescaled at the click of a button (the red one is approx 1/16).

As a 3d model it is still a bit rough but this is straight from the capture software (converted to STL). Took an hour to setup and take the pictures, then the uploading and converting process took another hour (this is all automatic so it was time spent doing other things). A few more hours tweaking in blender/openscad and I'll have a Matilda turret ready to print. And the best part is that its all done using free software.

Re: The 3D Printer Thread

Posted: Tue Apr 28, 2015 11:18 pm

by Woz

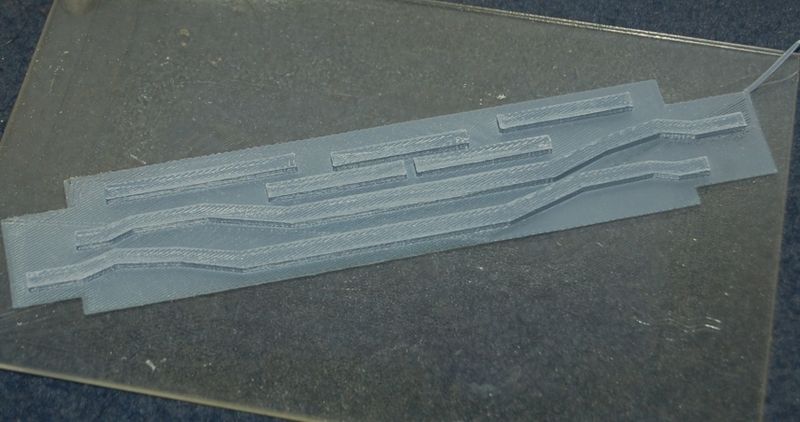

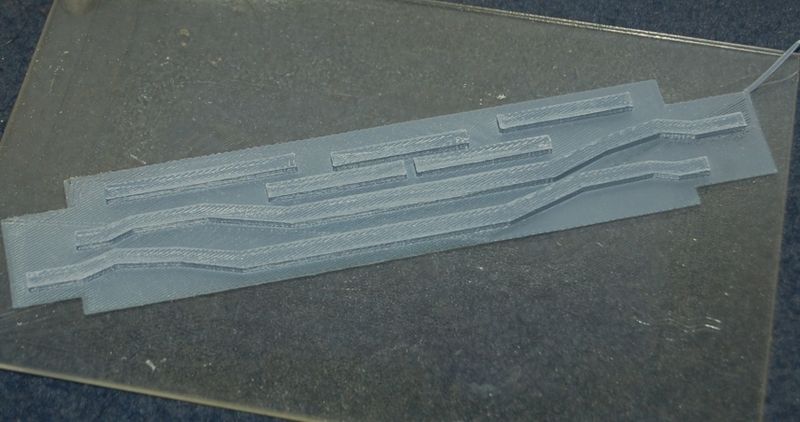

Had a go at printing with ABS.

Managed to do the parts with no warping (using hairspray) and only 0.74 mm out over a span of nearly 200mm.

Can you guess what it's going to be-

Re: The 3D Printer Thread

Posted: Mon May 25, 2015 1:27 am

by Woz

Re: The 3D Printer Thread

Posted: Mon May 25, 2015 1:28 pm

by wibblywobbly

After a lot of trial and error trying all sorts of bed adhesion solutions, I found that a Pritt glue stick was the best by a country mile. Just scribble it onto the glass, and print. When finished, run it under a tap (it's water solubale) and wipe with a sponge, hey presto one pristine print bed again. Slot it back in, push a button on the LCD screen and away it goes again.

The one thing that will lift a print, and I was amazed at how susceptible it made the adhesion, was leaving a patio door open. Just that tiny bit of air circulation would do it, so all doors and windows are now closed whenever I print anything. I can print hollow objects 100mm long and 200mm high without any support material, and nothing moves....except the contents of my wallet when I have to order more filament.

Now off to find the 3D software, I would like to have a play with it.

RobG

Re: The 3D Printer Thread

Posted: Fri Jul 03, 2015 4:38 pm

by nyleatherneck

I am in the middle of a LVT-2 build and want to get some parts 3D printed. I have a set of 2D CAD drawings but haven't had any luck converting them to 3D. Just wondering if any of you 3D wizards would be willing to help me get these converted. I also want to be able to sell the track links on my web site (radiocontrolcustomtanks.com) and would be willing to split the profits. PM me at

cjs9@cornell.edu

Thanks

Carl

Re: The 3D Printer Thread

Posted: Sat Jul 04, 2015 7:00 pm

by Woz

Tracks are very hard to do. They need to be exactly the right size to fit the sprocket otherwise the they won't stay on. They also need to be tough, so ABS on a home printer. Not sure how tough the Shapeways materials are. And you'll need a lot of them which'll be expensive.

I'm currently working on a set of very basic panzer tracks (only 20mm x 8mm). It takes 40 mins to print ten links, and they look pretty rough. I'll need about 180 for the tank I'm making so thats going to be 12 hours non stop printing (more if I get a few fails). That doesn't include time between each batch of 10 , scraping a set off then starting the printer going again.

If you want to make tracks to sell then you need to look into casting them. Make the originals with a printer (slightly larger to allow for shrinkage) then make molds and cast them out of something tough.

Re: The 3D Printer Thread

Posted: Sat Jul 04, 2015 8:19 pm

by RobW

Just to add, there are CAD bolt ons for casting, so you may be able to use those to calculate the shrinkage ahead of time (it's slightly out of my field). I'd be very surprised if Cornell didn't have software in the engineering department.

Re: The 3D Printer Thread

Posted: Mon Jan 11, 2016 10:45 am

by wibblywobbly

Re: The 3D Printer Thread

Posted: Mon Jan 11, 2016 1:37 pm

by 971wright

Hi Carl best way for you is to cast the tracks for the LVT because of the shape ,I think printed tracks would probably shed the paddles that are on LVT tracks , if you could get some printed to make casting moulds make them about 6% bigger because you get shrinkage when casting . keep the printed tracks to make more moulds, should get at least a couple of sets of tracks from each mould .

regards pete

!

!  Alwyn

Alwyn