Page 7 of 18

Re: [Support] M25 Dragon Wagon

Posted: Mon Sep 23, 2024 5:04 pm

by Ecam

Another neighbor has the exact tractor/loader (five years newer but the same hours - 149.9 hrs). This one was bought used two weeks ago but without any kind of warranty. After disassembly I found the turbine shaft in two pieces (guessing a defect as no debris found in the snails or impeller/turbine).

Re: [Support] M25 Dragon Wagon

Posted: Tue Sep 24, 2024 7:01 am

by MonsieurTox

Ah yeah you're super busy repairing all this stuff!

Now that's mechanics, no wonder why your models are so good!

Re: [Support] M25 Dragon Wagon

Posted: Tue Dec 24, 2024 11:22 pm

by Ecam

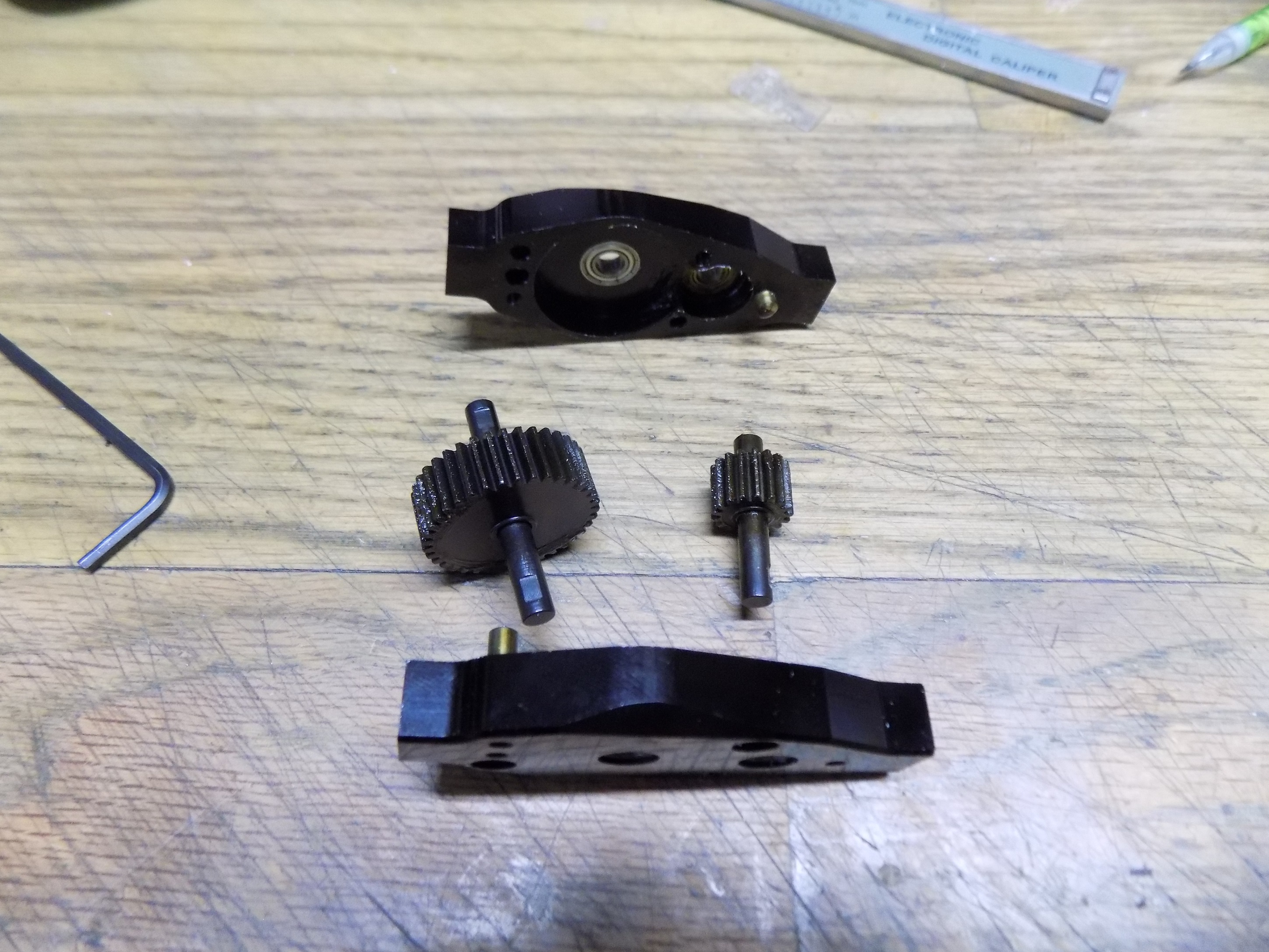

Well one of the big issues solved. This is the fourth attempt at a reduction transfer case. Two were advertised as reduction units and specified as 2:1 but turned out to be closer to 1.2:1, both returned. This one was ordered twice, after waiting for more than a month for it to arrive it was credited back. Found this one from a different supplier and it arrived about 10 days after ordering.

As delivered. 17 tooth input gear and a 37 tooth out (2.176 : 1 or so).

- 26.JPG (2.36 MiB) Viewed 132 times

- 27.JPG (1.48 MiB) Viewed 132 times

The front and rear axles are the same ratio, but the rear chain drive is is 2:1 reduction on the real Dragon Wagon. To get the front wheels to turn at the same rate I need to slow the front driveshaft to about half the speed of the rear's. I tried to press the shaft out of the input gear but ended up mushrooming the short side of the shaft (no workie). Remedied by drilling out the gears and installing new 5mm shafts with a little knurling and epoxy.

- 28.JPG (2.21 MiB) Viewed 132 times

- 29.JPG (1.6 MiB) Viewed 132 times

- 30.JPG (2.27 MiB) Viewed 132 times

- 31.JPG (2.01 MiB) Viewed 132 times

Still looking for the appropriate chain and then fabricating sprockets. It appears the real M25 uses 21 and 42 toothed gears for the rear drive. So using 17 and 37 should look pretty scale (and potentially work).

Re: [Support] M25 Dragon Wagon

Posted: Wed Dec 25, 2024 10:31 pm

by Ecam

Because this T-case has just two gears the output to the front and rear differentials will turn in opposite directions. The simple fix is to invert one of the diffs. Like the Tamiya semi trucks and the HL 6WD vehicles the most rear axle's drive shaft turns in the opposite direction.

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 12:02 am

by MrChef

Oh there we go. Good to see an update on this build.

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 12:21 am

by Ecam

If it helps, the first two pictures were taken about 20 minutes after arrival. The rest about an hour later. Warranty ruined a half hour after it was in my hands...

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 9:34 am

by MonsieurTox

Nice to see you back at it Eric !

Warranty ruined ? Do those kind of things have a warranty ? I'm not sure

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 10:48 pm

by Ecam

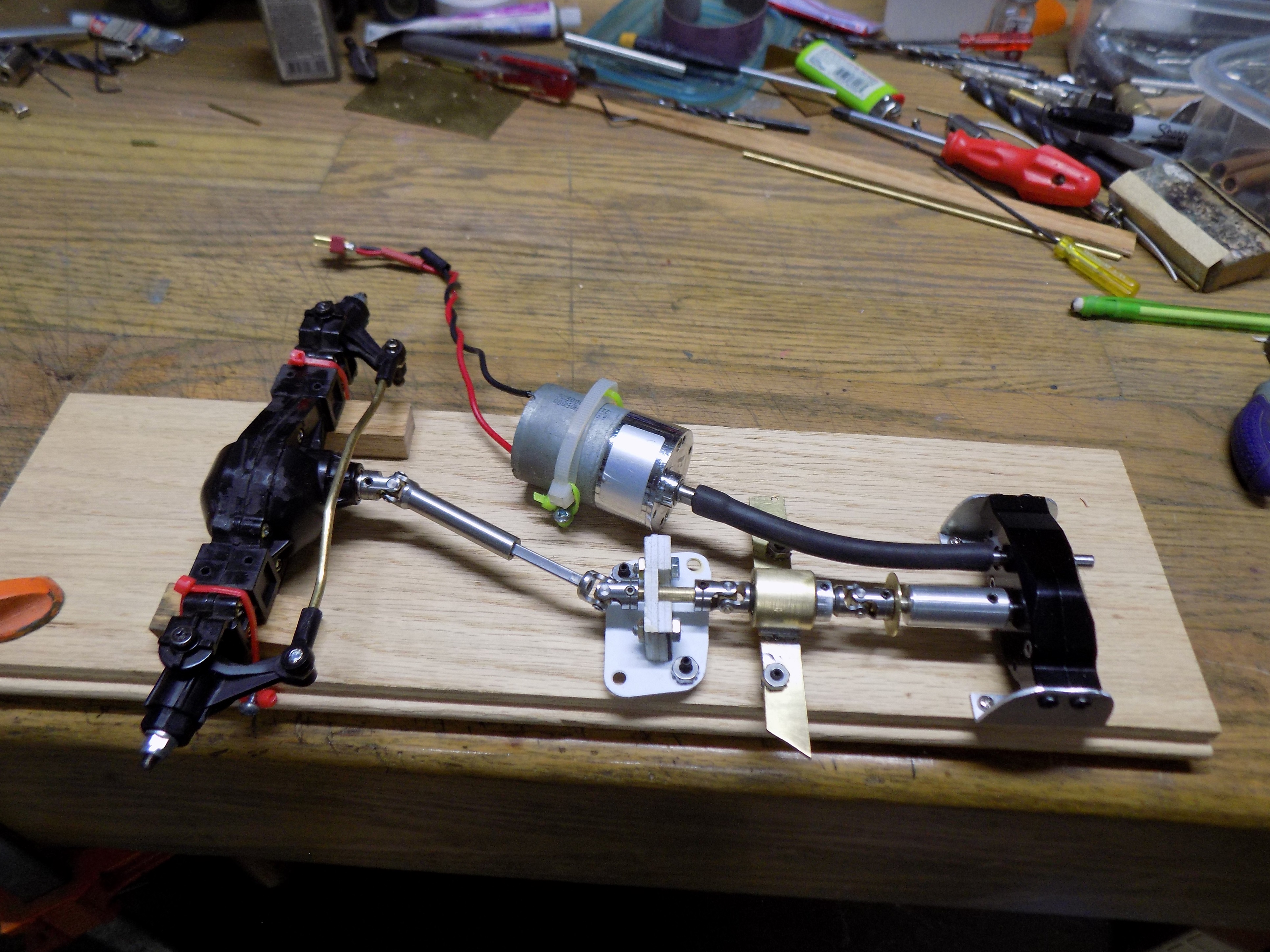

Just for fun...

- 32.JPG (2.49 MiB) Viewed 131 times

Why do we do this hobby? To enjoy ourselves. First test of a front axle disconnect. The pillow block will not be used (white styrene part). Instead the drive shaft will run from the brass piece to the diff. I can possibly shorten it up by an inch (25mm) if needed.

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 11:08 pm

by Herr Dr. Professor

Talk about CLEVER! Look at that drive shaft from the motor to the tranny! Geepers! Is that shrink tube? ...some kind of tubing? And the clutch! I can't wait to see the shifting for in action? Will it use a little servo. Geepers this is just such ingenuity!

Re: [Support] M25 Dragon Wagon

Posted: Thu Dec 26, 2024 11:20 pm

by Ecam

I borrowed the driveshaft from the pillow block to the diff from my little DUKW. And instead of borrowing the second I just used some vacuum hose from the garage. Yes, I intend to have a servo with a "fork" run the disconnect. The reason I made the display is in reality in action it would go unnoticed unless the rears were spinning in mud.