Hi,

Today, I got the ball bearings i ordered for the road wheels so i switched my attention from the rear ramp to them. I was anxious to see how the road wheels fit in.

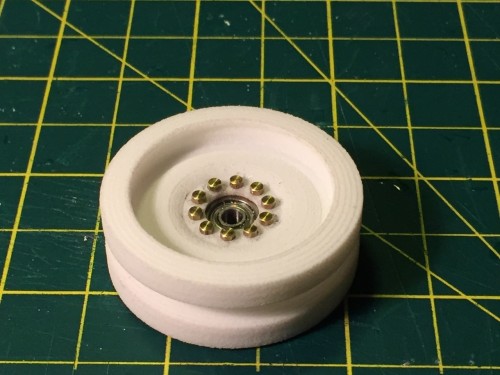

I changed my earlier bad design and decided to use 3x8x4 mm F693zz Metal Flanged Ball Bearing Bearings as central piece to the fitting. These can be ordered on eBay from China. Got 10 of these for $9 (with free shipping) so this is a good deal, it just takes a while to arrive. They fit the Shapeways road wheels and my axles perfectly, a pleasant view.

- Flanged ball bearings

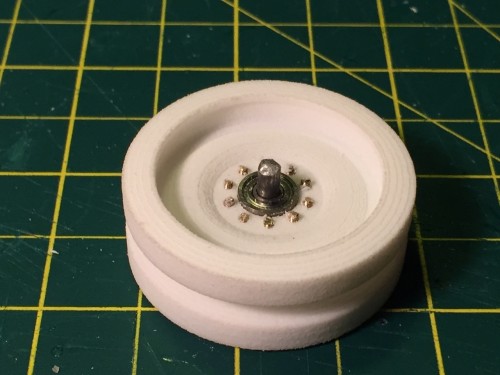

The axles are Knupfer metal 3 X 20 pins, then cut to the proper length. Can get these for a few pennies each.

- Axle

The Shapeways wheels are that, just wheels. The axles and fittings needs to be figured out. I made spacers out of 2mm plasticard to glue between the two wheels in order to get the proper spacing between them.

- Spacers

I have 20 shapeways road wheels worth $6 each for a total of $120 in expenses. Need to make 10 sets. The plasticard spacers were glued first to the interior of the inside wheel. Then i drilled the holes for the bolts from the outside and placed the bearings in the middle, making sure the rim of the bearing is flush with the spacer.

- Shapeways M113 road wheel

Then the outside wheel is glued to the spacer, making sure the holes for the bolts are aligned. The bolts are screwed all the way to the other side of the road wheels. These are Knupfer M1.2 X 8mm hex face brass bolts, worth a few euros for lots of 25. Need 100 of these in total. If you ever plan to do this, make sure to also order the special screwdriver made for these.

- Shapeways M113 road wheel

I cut the bolts on the other side so that they do not interfere with the roll. The axle pin is in place, very tight inside the bearings.

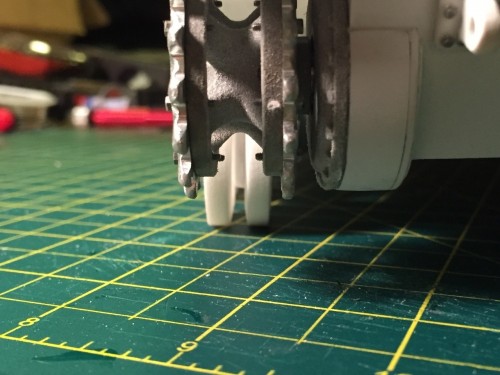

- Shapeways M113 road wheel

Road wheels are installed on the vehicle. Now, this is what i was really anxious to see. The space between the road wheel is very tight but they never touch. When i look at pictures of the real M113, the road wheels are also very tight together, so this seems ok... In any cases, i have no intentions of sanding the road wheels in an attempt to reduce the diameter.

- Shapeways M113 road wheel

Looking good i think... it worked. That is a releaf. On a project like this, major mistakes can happen anytime. But I like to do things i have not seen before. Its like pushing into the unknown. An Henntec adjuster was ordered for the idler. Hopefully, i ordered the right one...

- Shapeways M113 road wheel

When creating the road wheel fittings, it is important to measure everything in relations to the suspension arms so that the road wheels are perfectly aligned with the sprockets.

- Shapeways M113 road wheel

The centurion hub caps will be installed later. If the Shapeways road wheels had 8 bolts like it should have instead of 10, they would not look so crowded. The heads are a bit too big and it is normally the other end that should be present on the outside face, with a nut on each. However, i could not find 1.2mm nuts of the right size. With more knowledge and experience, someone can make a much better job i am sure.

- Shapeways M113 road wheel

Took me about 3 hours to make the road wheels, it was pleasant to design and to make these. The shapeways wheels are expensive but the rest was really cheap and it runs well for the type of use i will make. Ad Lav has a much better solution for heavy users.

Regards, Louis

I have to admit I'm blown away by your progress and ideas. The view into the personnel compartment is fantastic!

I have to admit I'm blown away by your progress and ideas. The view into the personnel compartment is fantastic! I have to admit I'm blown away by your progress and ideas. The view into the personnel compartment is fantastic!

I have to admit I'm blown away by your progress and ideas. The view into the personnel compartment is fantastic!