Page 7 of 69

Re: The 3D Printer Thread

Posted: Tue Mar 24, 2015 7:49 am

by wibblywobbly

I must be reading the wrong online tutorials, lol, jesus, it would take me a month of Sundays to link those objects together and get everything where i wanted it. Top marks for what you are achieving, it certainly gives me some inspiration.

Re: The 3D Printer Thread

Posted: Wed Mar 25, 2015 1:54 pm

by Woz

http://3dprint.com/53286/gizmo-3d-printers-fastest/

Still pretty expensive but for a new technology it's cheap as chips. The basic printer cost about the same as a good FDM printer

Re: The 3D Printer Thread

Posted: Wed Mar 25, 2015 3:11 pm

by wibblywobbly

If this scale of development carries on, we are going to see some very interesting machines within 5 years. Once the Chinese get their hands on it we could well see them dropping in price dramatically, like everything else.

Had my first thyristor blow yesterday, very frustrating, but ordered a couple on Ebay and they were here this morning.

Re: The 3D Printer Thread

Posted: Fri Mar 27, 2015 2:38 am

by Woz

More then just a printer-

Re: The 3D Printer Thread

Posted: Fri Mar 27, 2015 8:51 am

by wibblywobbly

A mere £2000 for an up and running delivered unit. Nice stuff but a tad expensive for my needs.

Currently printing my Kodiak dozer blade in two halves, already done a pivoting operating arm. It takes over 30m of PLA for each half and around 6 hours print time even running as fast as I dare. The finished article is as strong as an ox, and hardly weighs anything at all.

The quality is pretty good, already done one half, but sanding PLA is like trying to smooth granite with a teatowel. The most effective way is a soft wire brush attachment on a very low speed multitool, and then a thin coat of filler and more hand sanding.

The one thing I can say about 3D printers is that modelling loses that therapuetic side. When I am printing parts I actually miss that 'cutting up styrene' aspect, strange though it may sound.

Also found Design Spark software, it is free and provided by RS-Online, I am going to have a whirl on that as it seems the easiest to use out of everything that I have seen.

Re: The 3D Printer Thread

Posted: Fri Mar 27, 2015 11:13 am

by Woz

I find I'm still doing a lot of cutting and gluing, the printer just lets me print parts that I would've bought if I could (or print expensive parts cheaply).

Another thing I love is being able to take my "work" anywhere I go. I designed the Sherman small hatched cast hull over a couple of nights sitting in a hotel room (and started on a Matilda turret while I was sitting in the hotel bar).

Re: The 3D Printer Thread

Posted: Fri Mar 27, 2015 12:22 pm

by HERMAN BIX

Woz wrote:I find I'm still doing a lot of cutting and gluing, the printer just lets me print parts that I would've bought if I could (or print expensive parts cheaply).

Another thing I love is being able to take my "work" anywhere I go. I designed the Sherman small hatched cast hull over a couple of nights sitting in a hotel room (and started on a Matilda turret while I was sitting in the hotel bar).

Bar eh

Might be well advised to revisit the turret design...............juuuuuuust in case

Re: The 3D Printer Thread

Posted: Thu Apr 09, 2015 12:57 am

by Woz

Tonight I discovered a new bit of software "123D Catch" which converts photos into 3D models.

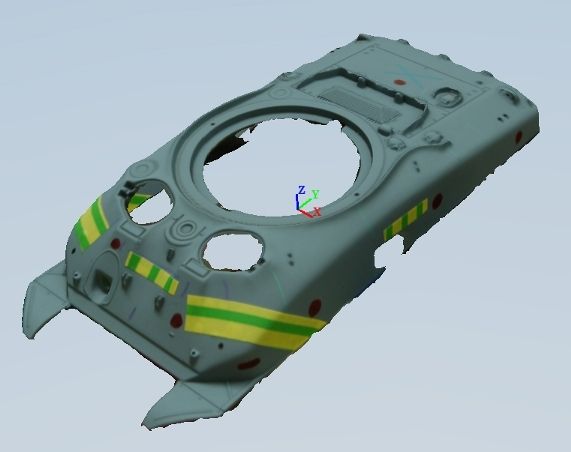

1st take lots of pics-

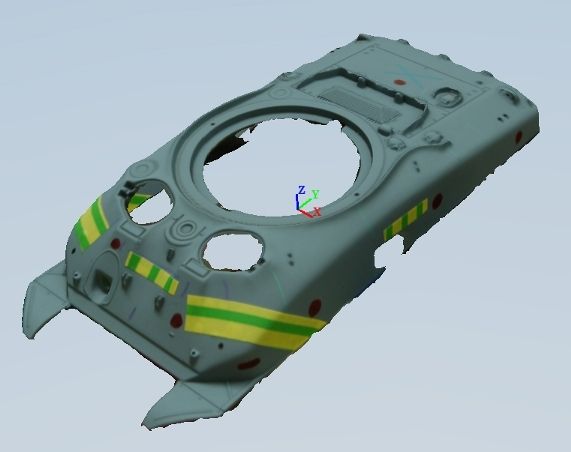

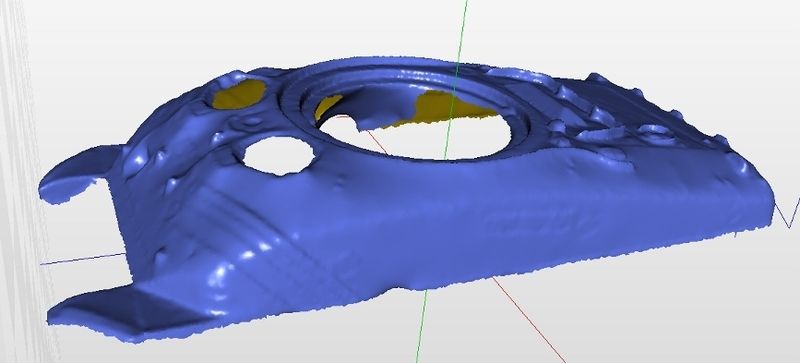

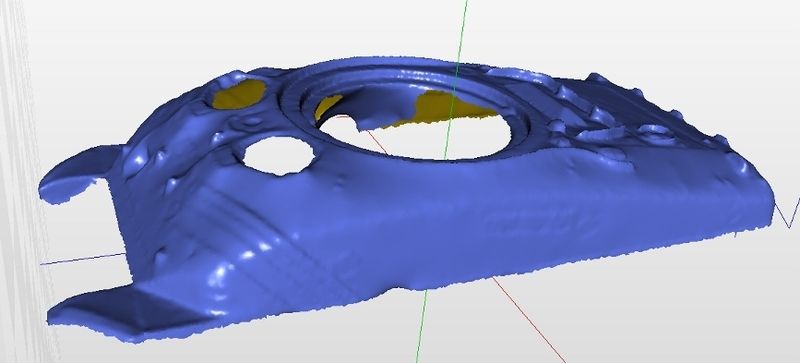

Then let the software do it's magic and all you need to do is edit the background-

Then export it as a 3D object-

OK I know it's rough bit but I've only had a few hours playing with it (and doing an entire hull was ambitious). With some better quality pics (and some blender trickery) this can make building any model a whole lot easier.

Re: The 3D Printer Thread

Posted: Thu Apr 09, 2015 4:43 am

by blimp

Now that's impressive ! Well done Woz

Re: The 3D Printer Thread

Posted: Sat Apr 11, 2015 1:59 pm

by wibblywobbly

That's not bad, some of the scanned items I have seen turn the Mona Lisa into Peppa The Pig. lol.

It wouldn't be beyond the realms of possibility to knock up say a turret using cardboard, do this scanning bit, and then get a 3D model to work on in Blender. Would be way cheaper than doing the original in styrene, far easier to modify etc, and should scan ok as well.