I added magnets to mount the top hulls to the Tiger and the King Tiger. The results are not neat but they work. That excess glue needs to be trimmed away...I use gorilla glue a lot, because it works on almost anything, no mixing and very strong...but as the stuff dries it expands and kind of whooshes for inches around.

Masking the area is called for but sometimes even that's not enough...The best time to trim the excess is half an hour once the glue sets. If you can fit a clamp on the objects the bond usually turns out very strong, indeed. Sometimes I'll make a glue "sandwich" if the part might slide out of place - droplets gorilla glue on the inner portion and super glue on the outside edges to hold the object in place. This technique has worked well for several small projects I've done. I always sand or file the surfaces good and rough to lend the adhesive tooth also.... I've mistakenly left the surfaces glued too smooth -for some reason carbon fiber beam resists roughening and wants to remain smooth-and later the thing just popped off with a screwdriver. Good to know if you want a Semi permanent bond i suppose: I glued the rx18 box into my tiger with one or two drops glue only, on purpose, , because I may want to move it later -and when i do the box will (hopefully) pop loose easily.

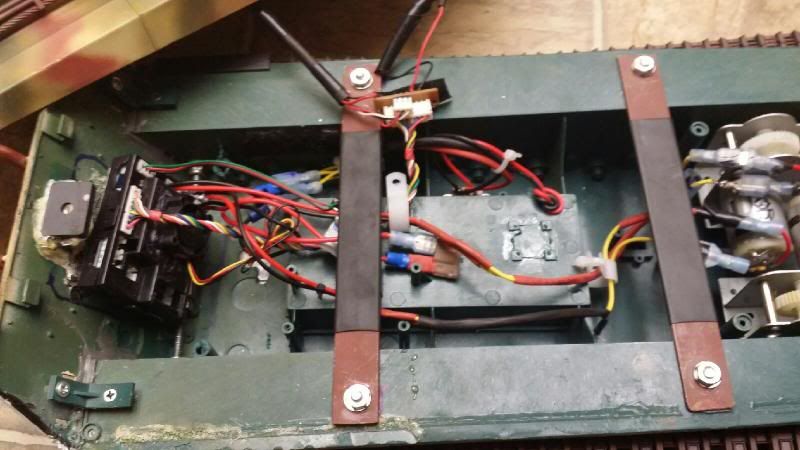

I also added more bracing to the king tiger hull, using aluminum strip. I don't think the hull will flex very much now but still thinking about reinforcing the floor and sides with carbon fiber...the CF bar stock is a nicer appearance then the little sticks, which are quite ugly -but for locations where they will not show, such as the hull underside, they might be wgat i will use anyway. The CF sticks are so thin you can make them fit anywhere and so light and strong they're just about the ideal hull bracing material, perhaps.

Considering how much even the plastic version tank weighs, hull bracing is almost a required project I think. Of course there's always the metal hull , for $100 more...but the taigen one for instance is basically a plastic hull with sheet metal insert...then you have to buy metal suspension Arms, wheels, tracks, and on and on...The more weight you add the more you will have to KEEP adding, it seems to me. If I ever go that far with the hobby I will bite the bullet and pay $500 for the all steel tanks! I'd sure like to know what battery and motors go into one if those, must weigh 50# for such a tank!

Back to the regular plastic tanks being modded by us peasantry- I bought some sheet styrene and considered adding that for strength. But after reading what otherpeople have done with tgeir tanks, the plastic seems too flimsy to be worth bothering with. Anywhere I'd reinforce with little old 1/8" styrene that you can literally cut with scissors, such as the hull floor, might as well use carbon fiber instead...

If I spot cracks in my hull one day, a spare hull is only about $20. Maybe I'll try resin next like some people do...perhaps even a quarter inch layer of Bondo would do the trick? Strong as concrete, very cheap, easy to work with and sticks to anything (but dam heavy so you would not want to use much of it).

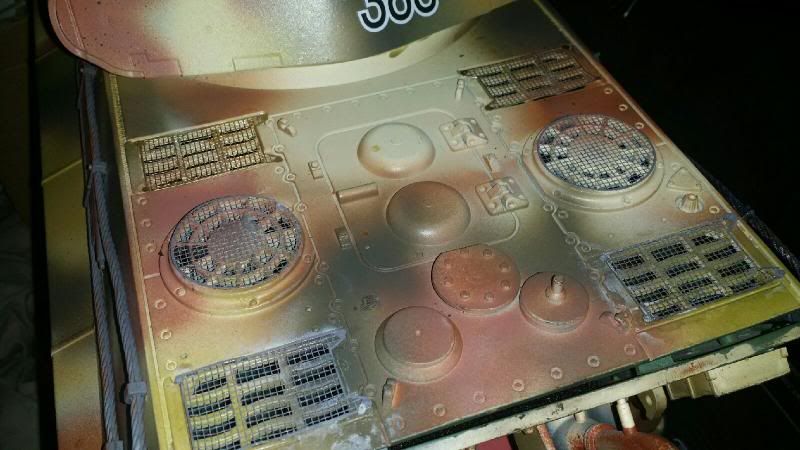

Above is the king tiger. I fitted the top hull beforehand and decided another brace would not block anything.

The black substance on the aluminum is heat shrink, to help insulate the braces in ccase of stray wiring.

The rear magnet to hold the hull, can be seen immediately above the RX18 unit. I switched to the 2.4 Ghz radio system and glad i did-works flawlessly. If i did it over again, i would simply start out with this system! It would save a lot of money and trouble.

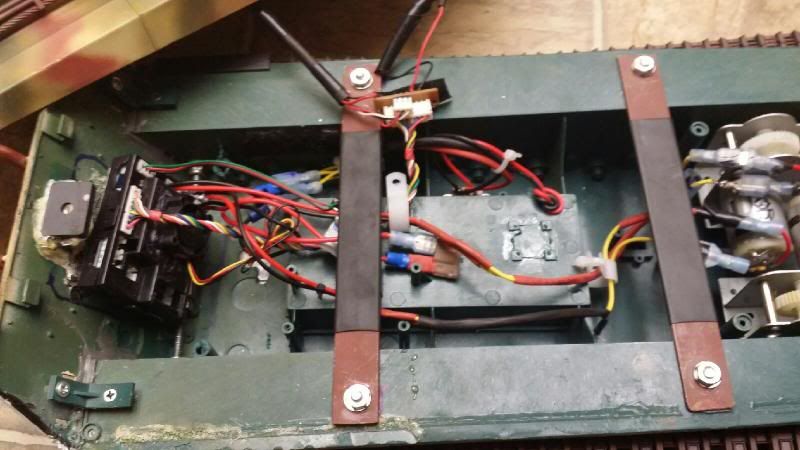

This is the tiger 1, with one brace added. I ran out of heat shrink...i just primed the aluminum, for now. The front magnet to hold the upper hull to lower is visible at the front of the hull. Two more magnets are glued into the hull, onto the cut down posts. They are the rectangular grey objects visible either side of the battery bay.

Since you need to add magnets in the upper hull, or at least a hunk of steel of some kind, this requires careful fitting, pretty much pin point needless to say! Because the posts have holes, and the magnets have holes, I cut down the posts a bit at a time and used strong glue for the magnets. I covered sheet metal screws in grease and screwed them in temporarily, to hold the magnets in place as the glue dried. Then I cut down the posts a little at a time with the dremel, until the two sets of magnets mated. I think i still need a magnet for the rear of the hull though.

After driving the tiger for a while, and watching the regular rx18 lose signal all too often-tank stops responding to the transmitter for several seconds, etc. - i decided then and there to just quit fooling around and throw money in attempts to fix these things and just sent away for the new radio system!

Planning to add another Heng long 2.4 Ghz system to this too, it works very well on the king tiger, as in flawlessly well. Since i had bought one before from the the vendor was nice enough to give me a a bit sweeter deal on the second system.

I still have a lot i want to do to the tiger1 , want to add a solid rear axle, more hull bracing, move the on off switch under the drivers hatch and sent away for those from artistic hobbies which cost $10 for two hatches. And Im getting antsy to repaint the KT...it just doesn't look right.

Does this KT look right to you? I think the paint needs redone, completely. Also zimmerit applique wouldnt hurt..thats a future project alright.

I really need to take a break for a few days-the wife is getting seriously jealous of all the time i lavish on my "mistresses"!!!