Something I've been doing the past days

- greengiant

- Warrant Officer 2nd Class

- Posts: 1138

- Joined: Tue Jun 26, 2012 12:15 am

Re: Something I've been doing the past days

Seems like the thing was just made to thin for any additional weight in the hull bottom.

What worries me is the cracks around the road wheel arm mounting points happening.

I look mine over and so far I see none on the outside.

Maybe that's because I put the plastic plates on the inside to cover the slots the arms pin run in and they are big enough that they are also glued over the area where the cracks may form.

What worries me is the cracks around the road wheel arm mounting points happening.

I look mine over and so far I see none on the outside.

Maybe that's because I put the plastic plates on the inside to cover the slots the arms pin run in and they are big enough that they are also glued over the area where the cracks may form.

Re: Something I've been doing the past days

I'll take photos of where the cracks are and post it here later. Seems that the screw holes were made by having the screws do it, I.e., they didn't drill holes big enough for the screws, but rather had the screws drill through the plastic - which weakened it. That's my theory. It's a fairly simple if tedious fix because you'll have to do all of them even those without cracks as a preventive measure.

Re: Something I've been doing the past days

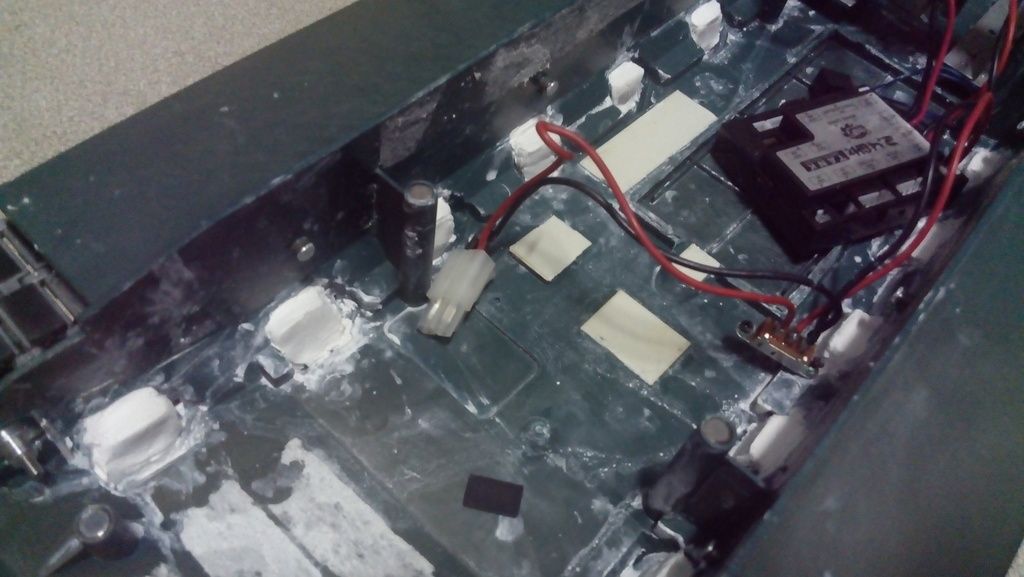

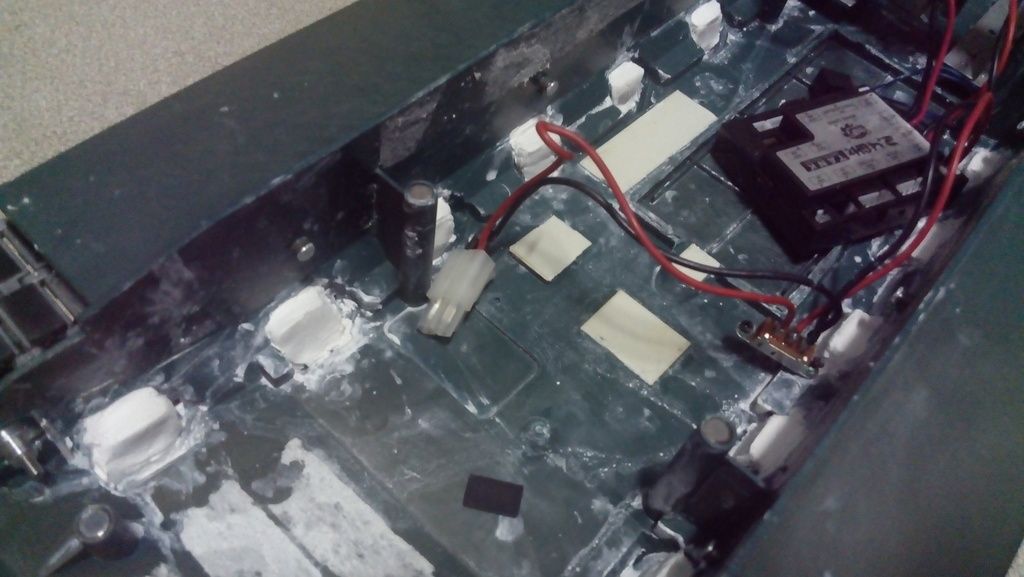

The following pix are of my Leo2 but applies to the M1. The first pic shows the crack and where it is located which is likewise on my M1. The second and third pix is the fix I came up with for the Leo2 which I intend to do and refine for the M1.

Notice the white line. The plastic is stressed to the point of cracking. In other similar areas where the screw connecting the road arms to the hull are located, actual cracks are found.

The fix I came up with is having a strip of metal the width and length of that plastic tab glued around it, basically to act as a clamp that prevents the plastic from further stretching then cracking. For added measure (as the metal strip can bend), I applied Milliput all over the area to really prevent any unwanted stretching and cracking.

Take note the sealed battery cover and removed battery compartment on my Leo2. I'll be doing the same to my M1. So far, my Leo2 has not shown any bowing-in of the lower hull despite the metal stuff and lead weights. It's the hull deck that warped probably because the plastic is thinner there and of the heat (these pix were taken last summer here and it was hot). The M1 lower hull is thinner it seems or uses softer plastic so I'll need to reinforce it to prevent any warping.

Notice the white line. The plastic is stressed to the point of cracking. In other similar areas where the screw connecting the road arms to the hull are located, actual cracks are found.

The fix I came up with is having a strip of metal the width and length of that plastic tab glued around it, basically to act as a clamp that prevents the plastic from further stretching then cracking. For added measure (as the metal strip can bend), I applied Milliput all over the area to really prevent any unwanted stretching and cracking.

Take note the sealed battery cover and removed battery compartment on my Leo2. I'll be doing the same to my M1. So far, my Leo2 has not shown any bowing-in of the lower hull despite the metal stuff and lead weights. It's the hull deck that warped probably because the plastic is thinner there and of the heat (these pix were taken last summer here and it was hot). The M1 lower hull is thinner it seems or uses softer plastic so I'll need to reinforce it to prevent any warping.

Re: Something I've been doing the past days

Here you go ATC...pretty simple...I just cut some scrap Helicopter boom the two at the battery box are press fit in...solid as a rock...the one at the top I glued with some plastic dust...that is also solid...I can lift the hull with it lol

I'm with Giant so far....I took a look at the hull for cracks and had none...knock on wood

ALPHA

I'm with Giant so far....I took a look at the hull for cracks and had none...knock on wood

ALPHA

Re: Something I've been doing the past days

The plastic tabs to which the first suspension arms on either side are attached on my M1 have the cracks. To be fair to HL, the plastic tabs are thicker compared to that found on the Leo2. Still, I'd reinforce it to be sure especially since I like to drive my tanks hard as they are supposed to be.

Thanks for the pic. You just gave me an idea to copy. I have some aluminium curtain rod that I can use as bracing.

Thanks for the pic. You just gave me an idea to copy. I have some aluminium curtain rod that I can use as bracing.

Re: Something I've been doing the past days

I'm waiting for mine to break offatcttge wrote:The plastic tabs to which the first suspension arms on either side are attached on my M1 have the cracks. To be fair to HL, the plastic tabs are thicker compared to that found on the Leo2. Still, I'd reinforce it to be sure especially since I like to drive my tanks hard as they are supposed to be.

Thanks for the pic. You just gave me an idea to copy. I have some aluminium curtain rod that I can use as bracing.

ALPHA

Re: Something I've been doing the past days

My M1 is the model below yours...didn't come with the steel boxes...so HL must add that for the top of the line models ...because mine didn't have the bracescalawag wrote:The M1 I just bought has a metal brace between the Idlers at the front of the hull. I will post some pics when I am able but I am getting ready to take my tanks to a show this weekend at the moment.

The M1 I bought was a "platinum" model which came with metal road wheels, tracks, sprockets, idlers and steel gearboxes. Do yours have this brace at the front? If not I wonder if it is a new addition that H/L have made, or if it is part of the "platinum" editions extras?

Paul

ALPHA

Re: Something I've been doing the past days

You never know with HL now days...when I found my listing for my tank it took me by surprise...what was even more surprising was the bearings in the road wheels...something totally off the wall for HLscalawag wrote:Ah ha, that would make sense ALPHA. I know one of the sets of metal idlers comes with a metal brace as part of the package.

http://tankarmy.com/heng-long-tank/prod ... ngs-p-1707

I wonder if the bowing becomes a consistent issue, will H/L make this brace or something similar a standard feature across the range?

ALPHA

Re: Something I've been doing the past days

You might want to pull the wheels and check the idlers...You'll probably put a hentec...but it's good to do if you haven't done it already...found one of mine was binding....apparently the brass bushing wasn't totally seated...and when the screw was tightened locked the wheel up considerably ...I just tapped the bearing with a small hammer and she was good to go...also found one guide wheel tower was short...similarly to the idler ...if you tighten the screw ..it won't turn...made a plastic extension for the tower...and filled the outer part where the screw enters the wheel down a tad ...now all is goodscalawag wrote:Yeah I had the lithium battery as well, which was a bit of a surprise, but I have swapped that out for a bigger LiPo already.

I have done most of the internal work now, axle supports, IBU2, Tarr1 smoker, viper volume control, removed bb unit and added LED flash, amp for the sounds and uprated speaker. I might add an IR battle system, and servo gun recoil but not really sure at this point. Now I have seen your bracing I might well add some at the battery box.

Will be moving on to the outside detailing soon, but I think this one will be an early M1A2 rather than any of the updated models. I have a Leopard 2A6 which I will be working on as well, So might take some time to progress. Also waiting for the Chally II of course.

Even with it's little flaws though...I really ike this tank

ALPHA

PS...I too didn't use the provided battery...it's cool that it's there though....and have also installed a Tarr ...the rest I'm pretty satisfied with for now...might add recoil later if I can design one that works and doesn't take up too much space

Re: Something I've been doing the past days

You have to put up some pictures Scalawag...it's a good time to do it...there's a lot of M1 builds going on...Toni just finished his...did an outstanding job with the box stock model ...so you know that old idiom...the more the merrierscalawag wrote:Yep I love this tank too, I'm really enjoying working on it.

Thanks for the tip on the guide wheels and idlers ALPHA, I will definitely check that out.

ALPHA