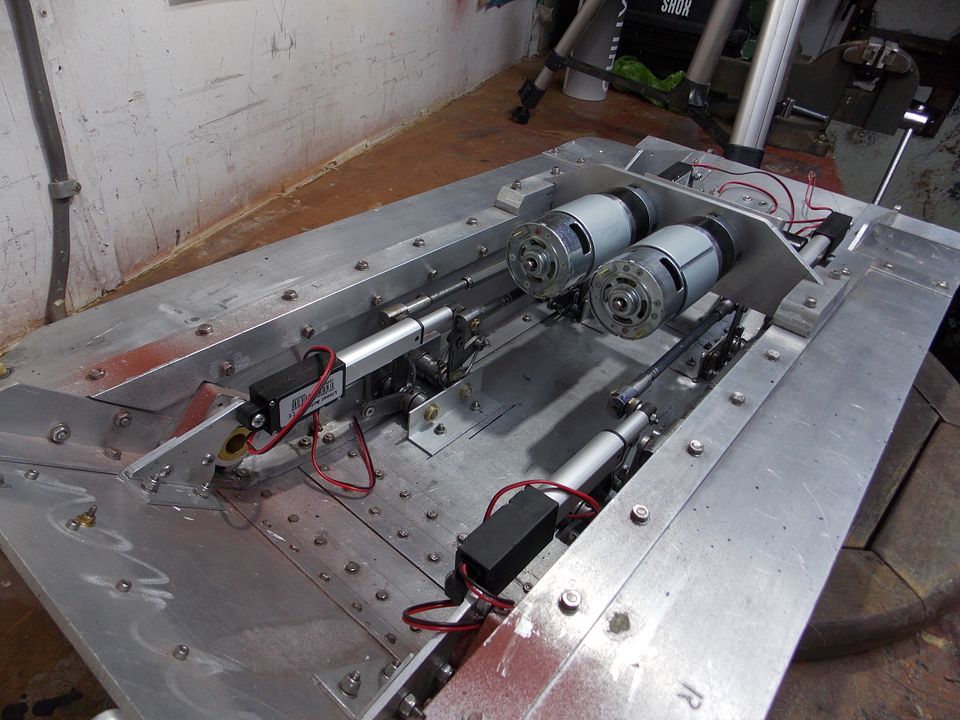

The motive power was going to be two cordless drill motors with their gearboxes. I had two of the same model but when I opened the drills up I found they had two different motors. The gearboxes seemed to have the same gear ratios albeit with slightly different designs. I was going to replace the motors so at least they were identical. One gearbox could not run without locking up. I abandoned them and found two motors with gearboxes on Aliexpress.

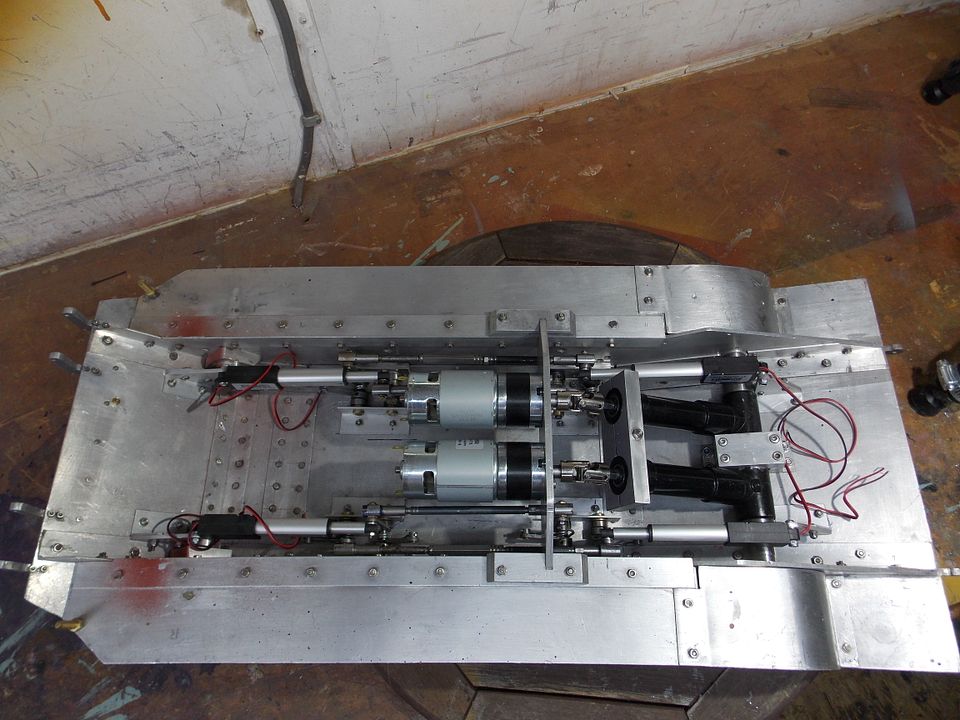

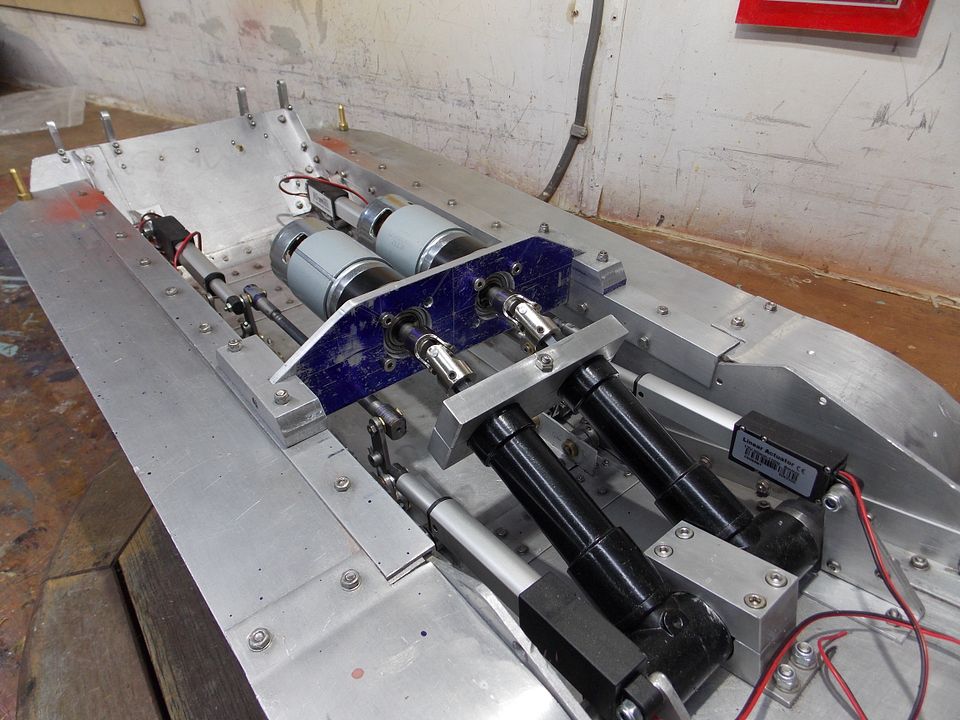

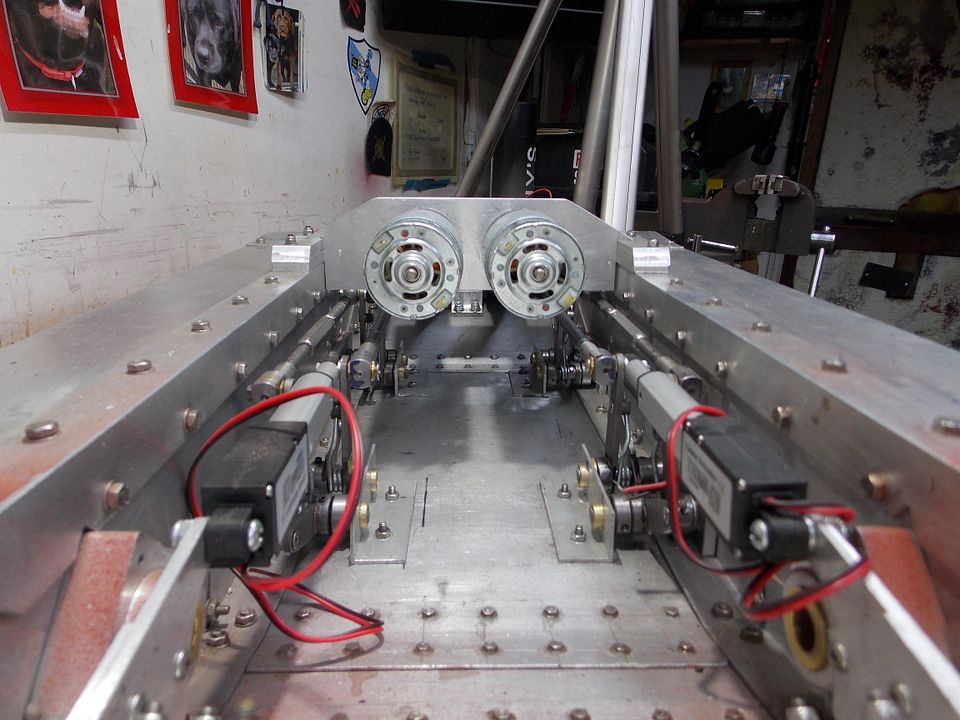

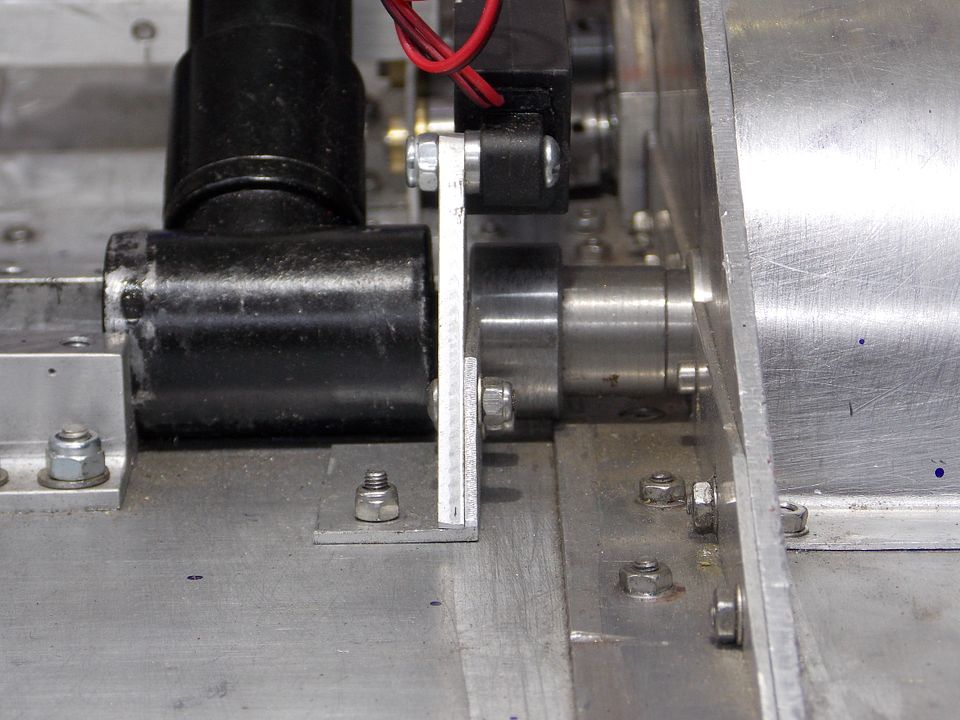

These motors and gearboxes are a little wide for the hull hence the long black tubes. These are right angled drill attachments for power tools with the drill chucks removed. I have machined two shafts that slip over the shaft in place of the chucks.

There will be plenty of space in the hull for batteries and the other gubbins .