Right folks, back again, though with a distinctly mixed feeling on my recent progress! While I'm really pleased that things are still moving at the speed they are, the need to do every single job four times before it can be officially called finished is rather disheartening at times!

Right now I'm pleased to report 90% completion of the second track assembly and final assembly of the first one! I've also managed to order the remaining 6 sprockets I need but they'll be a few weeks coming so the other two tracks will have to wait for now... That said I can still get on with preparing the wooden parts and putting together some of the reinforcing structure while I'm waiting for them so I'm by no means at a standstill. I also have one of the two rocket pods still to finish but I'm fast running out of cutting discs and don't want to risk breaking my last one before the backup I ordered today has a chance to arrive!

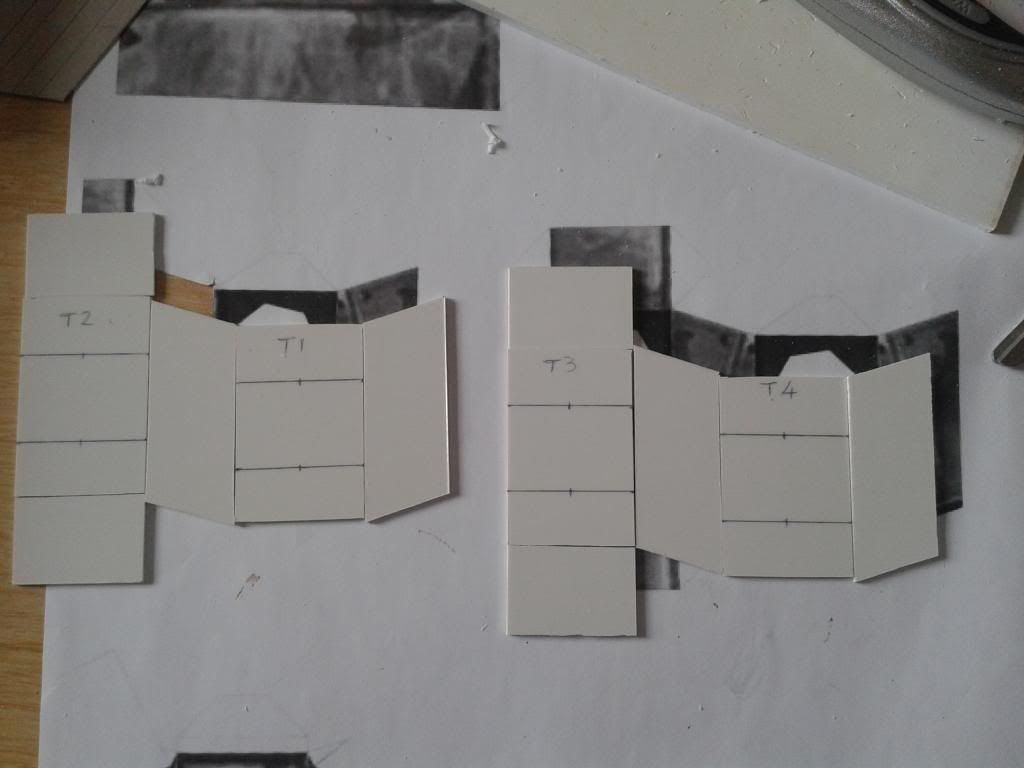

Another pleasant development is a little of the final skin, currently just two of the armour plating pieces for the completed tracks. It still doesn't do a great deal to help with visual scaling (read - still looks like a 1/6 build

) but it's a welcome start and at least a start to covering some of these big white spaces!

Anyway, I'll show some pics of these bits in this update later so no need to explain it in writing! First up though, I took a few additional shots of work I did a while back that never got a decent showcase.

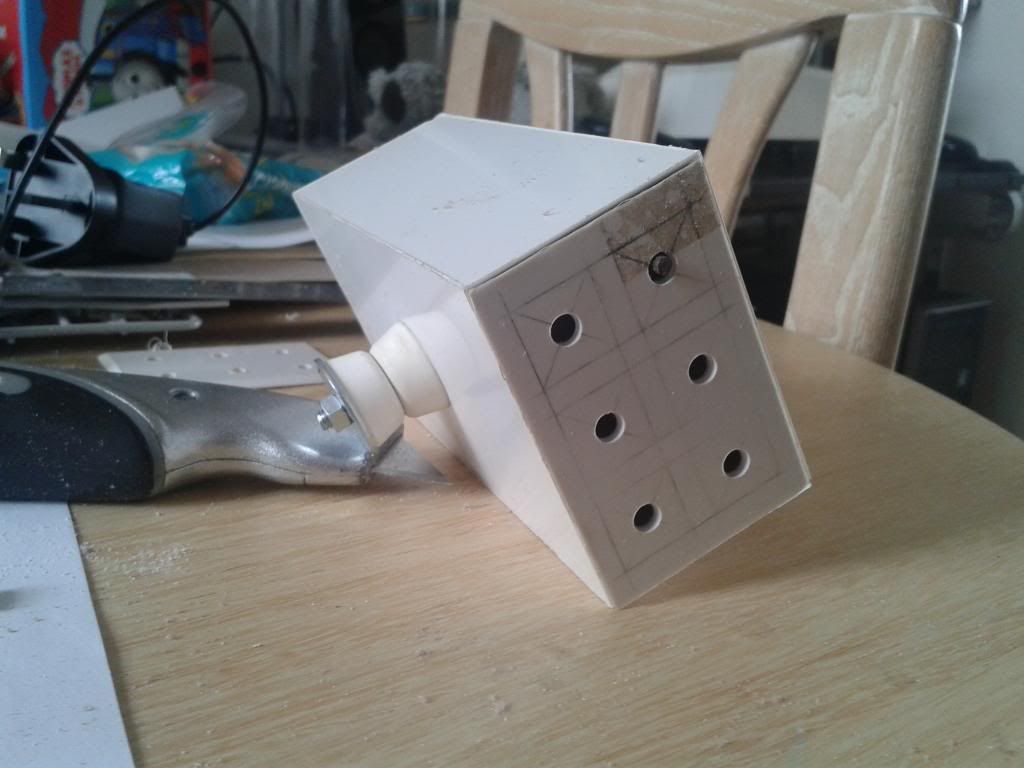

First up here's that rocket pod I still need to work on. It's appeared in previous pictures so nothing new here...

Here's the finished one, it's also appeared before but now it gets it's own spot in the lineup! The missile tubes are something like 12mm pipe and whatever material I used happens to be rather tough and heavy so the next one will have to wait a while if I want to cut it nicely. On the other hand I have considered just doing it the old fashioned way with the hacksaw and bench-grinder so that's always an option!

As you can see here I've just left all the tubes as empty for now. They'll be addressed much further down the line when I start thinking about dramatic pyrotechnics

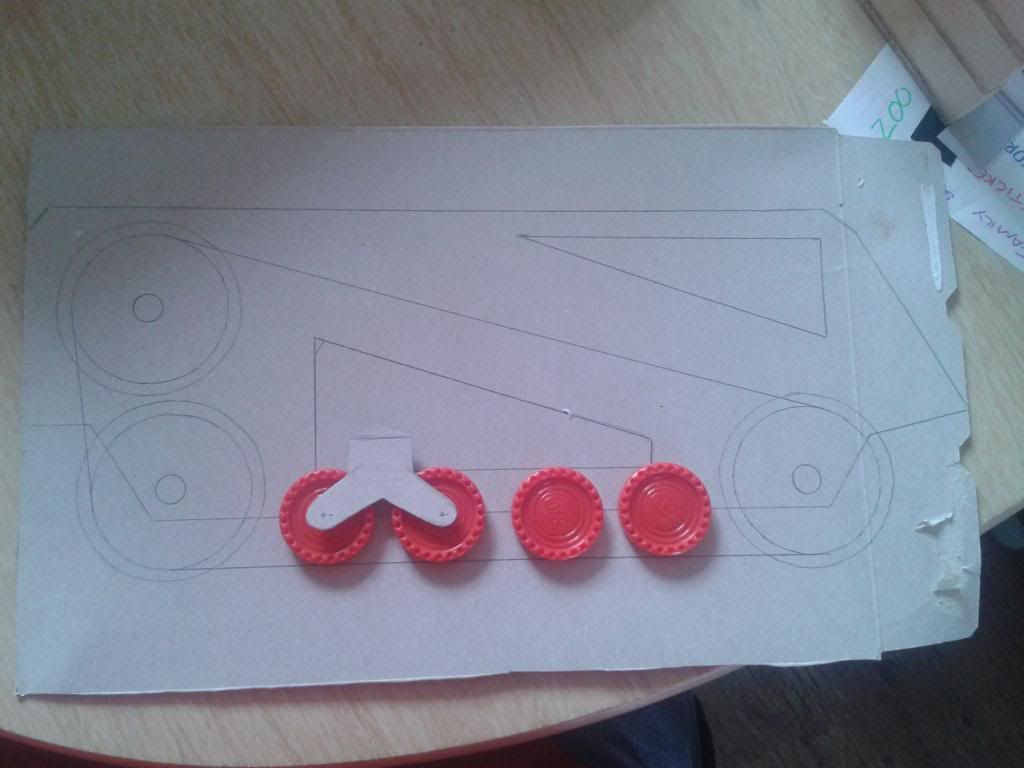

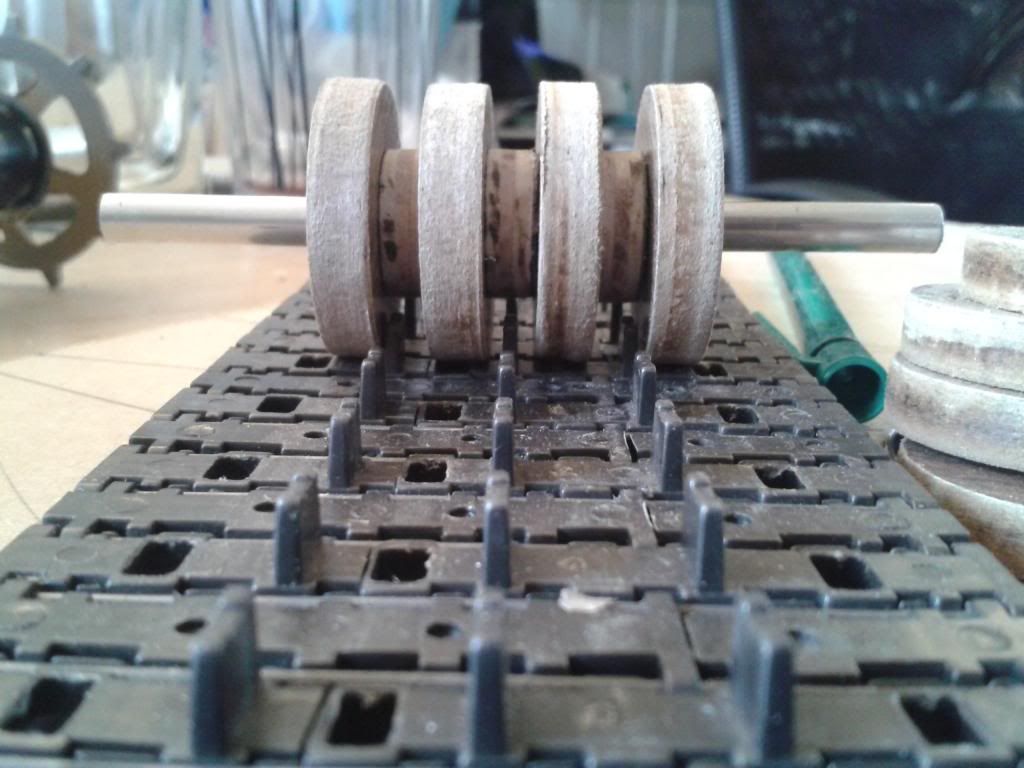

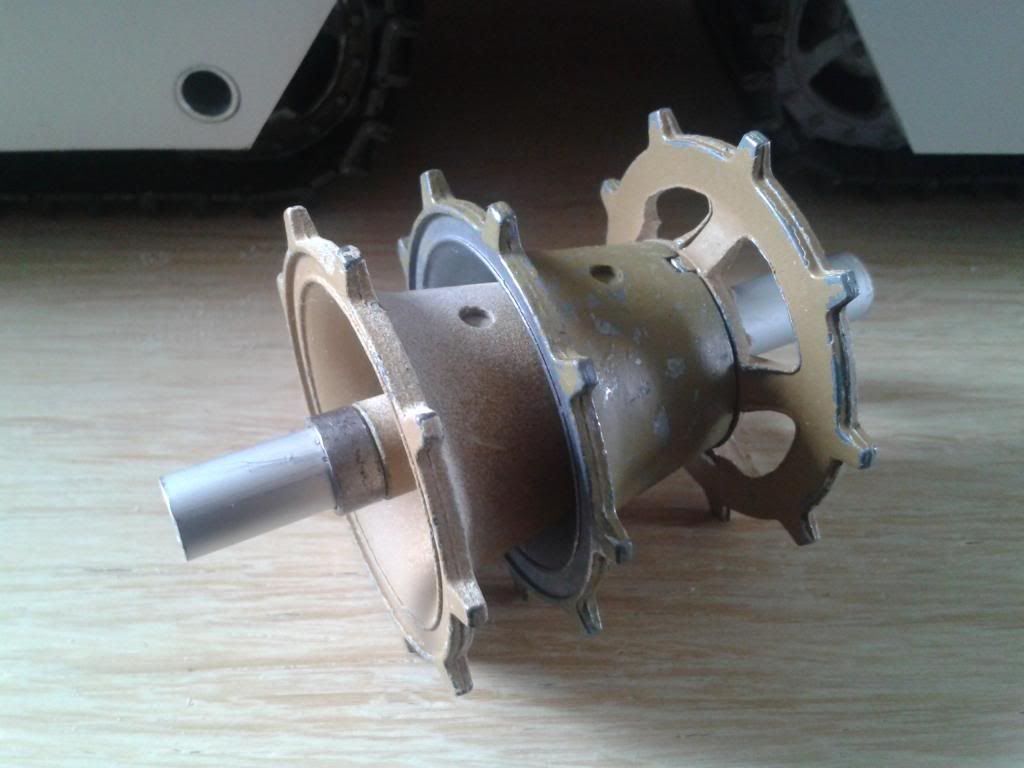

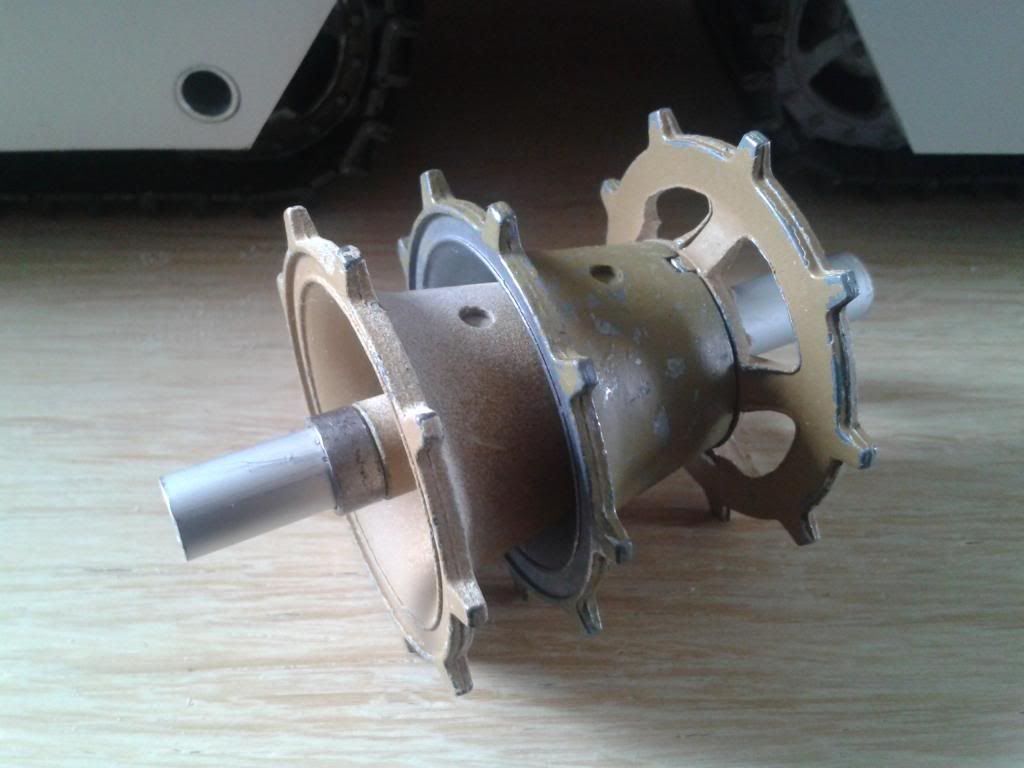

The other assembly I haven't showed since I finished it is the 'idle' sprockets that will run on the ground. I had a few thoughts about how to put them together but with my limited resources and very basic toolbox I figured this was the easiest way. BEsides, I've always wanted this tank to be a simple dismantle job after it's finished for repairs and upgrades later in life so I stayed with that philosophy here too.

First up, the gear face is simply bolted to the axle at the correct position with the excess bolt being cut off. I then slotted one end of the bolt to allow future removal. This was made necessary by some poorly measured axles anyway so isn't as forward thinking as it may seem! Remember I said the first track I finished was a little off-centre? I recut all those axles to fix the problem and hence needed to remove these bolts...

After this part of the assembly is secure it's a simple job of sliding on the two rear sprocket pieces and finding a way to secure them. It turned out to be impossible to use another bolt here so instead I cut some of the pipe I'm using for the missile tubes and used the small pieces as collars. The diameter of the two pipes makes them a perfect fit so I simply smashed it with a hammer for a while, to create a slightly ovoid collar, then fitted it to the axle. After fitting I used a spare sprocket to hammer the collar right onto each piece and this stopped the unsecured rearmost piece from moving but I doubt it will last for long what with vibration and such. That's one of many potential issues that I'm happy to deal with later though, so for now they look like this!

That was the only catching up I had to do so this is new stuff from here on out! I've spent a LOT of time recutting these axle pieces this week as I'm apparently overly anal when it comes to having my track run central. It's been incredibly frustrating as I'm working to a tolerance of <0.5mm but don't possess ANY tools that make that a realistic target! But of course the good thing about being overly anal is that I achieved that target anyway! We OCD types rarely take no for an answer...

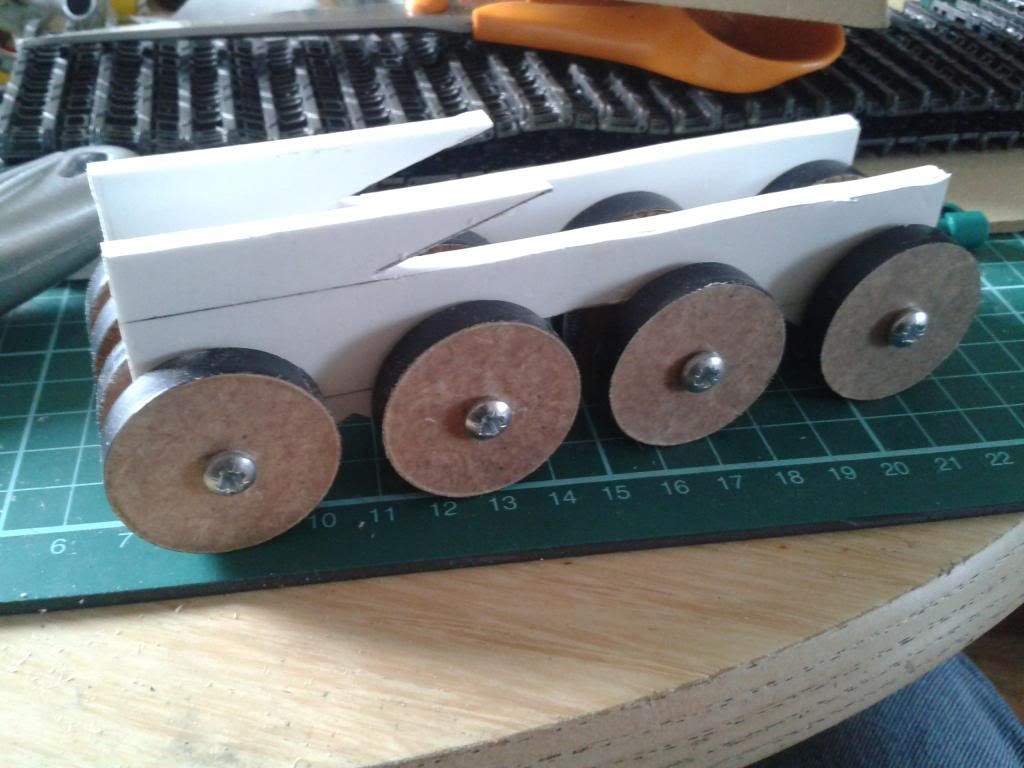

Anyway, once I was finally happy with all the axles I'd built for the first track (read - prototype track) I finally decided it was time to fix it together as it will be in the final build! So here's one I made earlier...

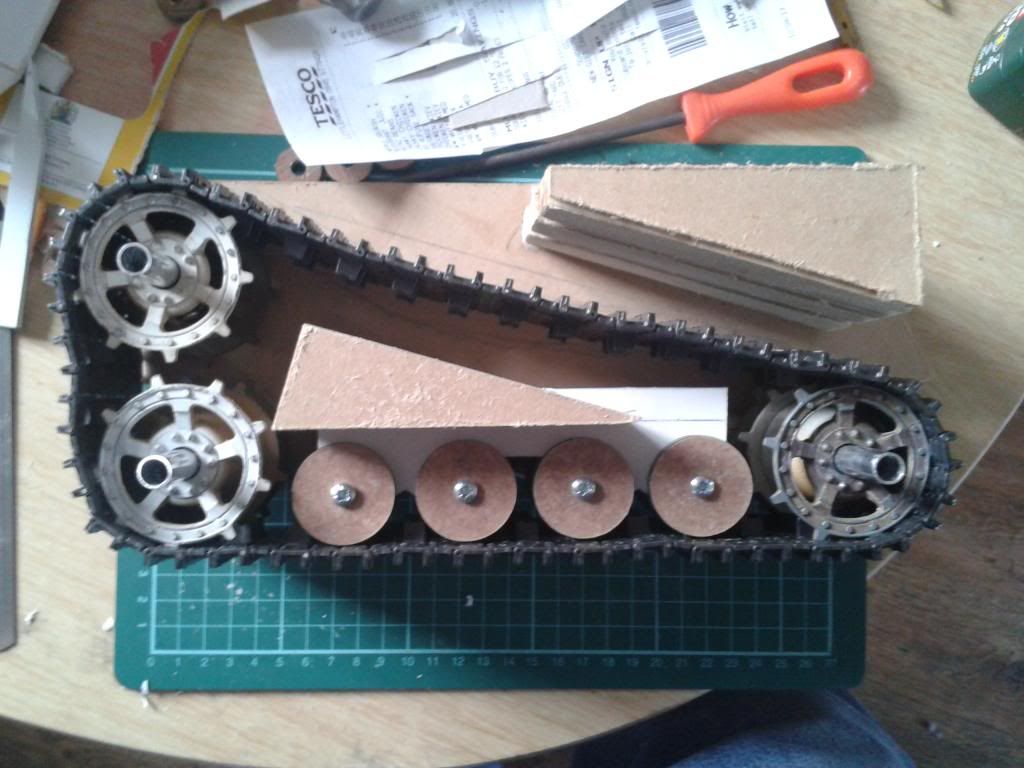

First off, remember the side piece was removed from this track a LONG time ago, it made life (and especially photography) a lot easier, but I won't be making the other 3 like this... What's new in this shot is that I've removed one side of the wooden reinforcement piece and added 4 easily removable bolts through the wooden structure, the track armour AND the hull itself. The main purpose of these is of course to add rigidity by sandwiching all the different layers together. However, it also allows for fairly easy removal of the wooden sub assembly at any time, even post build. In addition to that, I figured it makes it possible to actually remove the entire track assembly, axles track and all. I'd just need to remove the bolts and seperate the glue between the hull and track armour and any potential problems I may encounter in the future would become significantly easier to rectify.

In this shot I've replaced the other side of the wooden structure both with suitable glue AND 2 long screws. These will help the sandwich structure retain it's strength once complete, although I forgot to place two on the other side before bolting it to the hull. This can easily be remedied at a later date. Both idlers are in place here but the drive axle was being remade at this point.

This shot shows how the bogey assembly has been (temporarily) secured in place inside the track assembly. Notice it's been fixed to another piece of plasticard the full width of the housing to prevent sideways movement and a small clout nail is currently stopping it from moving during track motion. It will be replaced with a suitable screw once I get one from the shops! This shot also gives the best idea of internal construction too, and how much of what has been built will be invisible to anyone seeing the tank in a normal situation...

This shot is simply the bogeys mounted and the side piece attached WITH GLUE! Gasp... Yep it's finally on permanently now that I'm happy with the method for building these things! The pencilmarks on this piece are all wrong so can be ignored until you see the nexta image and realise what they are...

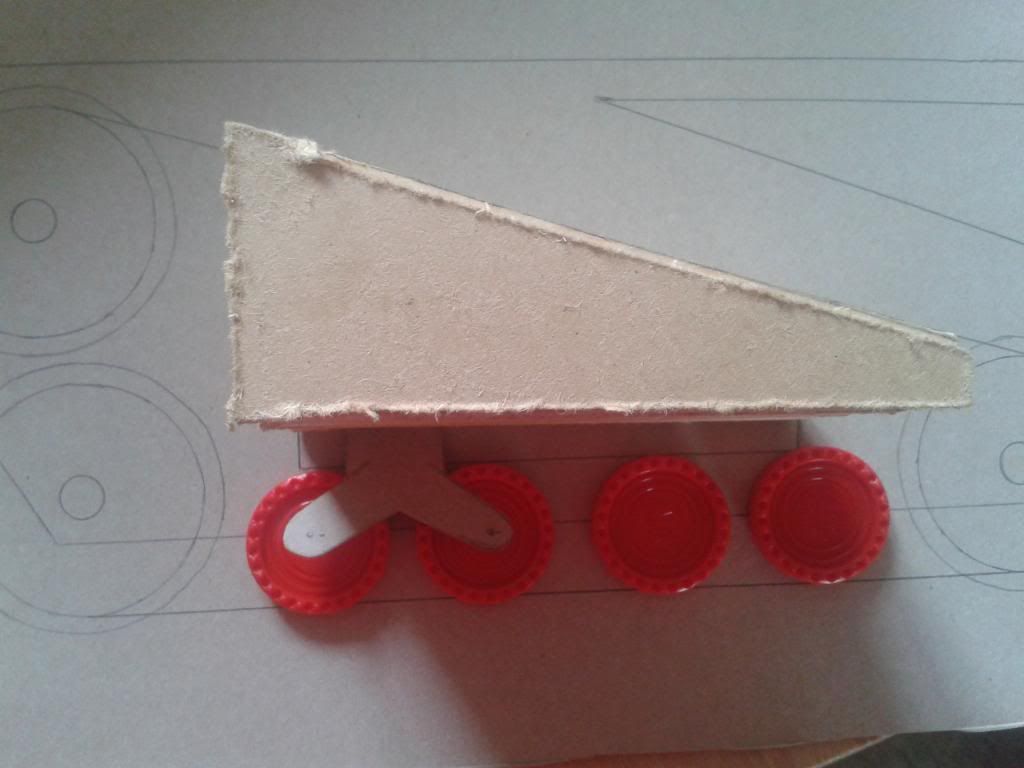

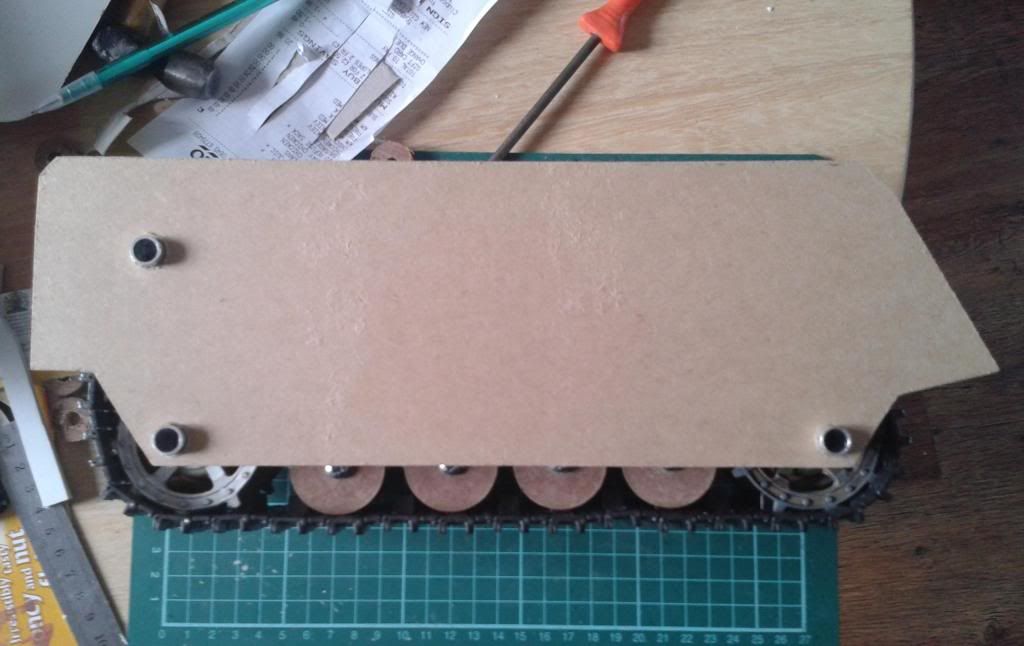

Yep, time for armour plating and it couldn't have gone any better! I for one think it's really great being able to see the whole assembly without the axles sticking through visible holes. It's basically 5mm foamboard (or similar) which I liberated from a building site when one of their signs broke in half. It's very easy to work with and I managed to get a really good fit from it. I sanded a 45degree chamfer onto all the edges, as this is how the tracks appear in official images, and then added some panel lines which I THINK are deep enough. I'm not going to change them until I decide how to add the plating to the other track surfaces. The trouble with adding more material to the other sides it that it will interfere with the turret height (not to mention these side plates I just finished... But for now this is a FINISHED track! The drive axle and track are in there and it's all PERMAFIXED! Of course the joy of this design is that despite this I could dismantle the entire thing in about ten minutes, but if I don't WANT it to come apart, it won't!

There's quite a lot of work going on between these two images but this is basically the rear track on the same side finished to the same extent as the front one save for the bogey assembly. You can see the side plating isn't glued here and it actually still isn't as it's harder to remove the rearmost idler on this track and I don't want to glue myself into a corner just yet! Once the bogeys are sorted though, this track will be finished too. I'm just putting off cutting all those wheels out again as it took ages last time...

Here's a side shot of both 'finished' tracks and armour plating starting to make an appearance. I'm well aware that they're still huge and don't add much in the way of detail but I think they already make a HUGE difference to what was essentially a large flat white surface with holes in. And remember, all the surfaces will have at least SOME similar details on which will help a lot. It'll continue to look completely out of scale until I start adding things like shovels though I think! Also, please remember this is a faithful recreation of a tank that never existed! I'm trying not to take any liberties and as this is what it looked like in the game, this is what it has to look like now!

Gratuitous track shots... Think the plating looks better when your eye isn't drawn to the rest of it which still looks pretty crappy by comparison... Bear in mind that those bogey wheels need some sort of detailing before I consider them finished. I like wood as much as the next man but not for tank wheels!

Added my Tiger Commander for scale, and while he does look hilarious I think that's about the scale I was looking for! Hard to know since he has no legs. Especially in the second image...

And now for the first time in a year and a half, some scaled comparison shots! Here's the Mammoth as she stands now next to the little old Tiger...

Hope you like it, how do you reckon she'd look on a 1990 battlefield? I'm betting it would make quite a few tankers pretty nervous myself! Not sure what the next update will be while I wait for bits and pieces but rest assured you'll know when I do!

NB. Almost forgot to say, I've seen this thing run

I made one of the drive axles without cutting it to length and then ran it with a power drill but couldn't really get a video of it as I couldn't support the weight of the track! It wouldn't be an issue now as all the reinforcing has been done and I can now LIFT the thing by it's tracks (very different from a week ago when I could hardly lift it anywhere at all without damaging a join!) but sadly I don't have a long drive shaft anymore... I'll make up another long one when I can and try to get a video now it's looking a bit more finished but I tell you what, it was pretty damn good! As you'll know, I already have the gearboxes in place but not the rest of the hardware to make them run so I'm wondering if it's possible to get the gearboxes running directly from a battery somehow? Just whack some wires in there and create a closed circuit? I can take the battery from my tiger but sadly the controller seems to be dead for it (otherwise I was going to rig it up to run from there!) Any advice on this would be great and also allow for a video of both tracks moving together, something even I haven't seen yet! Failing that I recokon I should have all four tracks done within a month (or Christmas at the very latest!) so fingers crossed we'll see something interesting soon!

Cheers for looking, please tell me what you think. Do the cannons look too big yet?