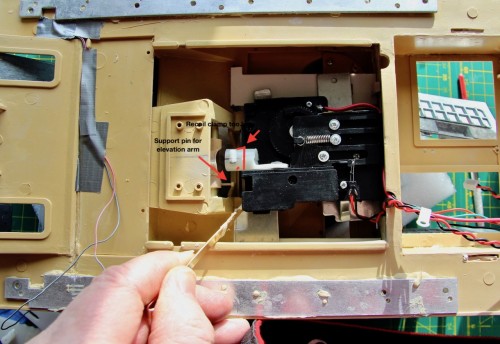

I made some recoil unit support brackets from spare sprue frames. The two I've made will be bonded into the casemate. After that, the unit can be screwed to the supports. Doing it this way should provide access later from the (detachable) casemate roof, and from below via the upper hull.

- StuG IV support and retaining brackets for recoil unit

Here the brackets have been bonded into the casemate roof ridge with two part epoxy.

Looking at the recoil unit, which is loosely in the desired position, you'll see that I've drilled into the L/H gun trunnion, and put a 1.5mm brass bolt in there. The bolt is to act as a locking key in the elevation arm, once the arm has been bonded to the trunnion.

While the recoil arm should now just about have room enough to operate, it will still have to enter the breech by about 10mm, and that could lead to problems with sticking and obstruction, even though I have opened the breech out about as far as it can go.

Anyone contemplating using this Asiatam StuG kit, should give a good deal of thought to the fact that the kit appears to have been designed with a 'static' status in mind. Why? Well, because there's no obvious, nor any easy way of mounting any kind of gun operating system (Airsoft, IR etc) in the upper hull.

My plan is to shorten the recoil arm so that it can travel 19mm (full stroke) before entering the breech. I'm thinking of screwing an operating arm to the end of the barrel, so that no part of the mechanism will be proud of the barrel itself, and the screw itself will be short enough to allow the xenon flash cable to pass down the barrel unhindered. But that's for later, when the plan takes shape. As usual Click to ENLARGE the pics..

- Stug IV- recoil retaining supports bonded in place

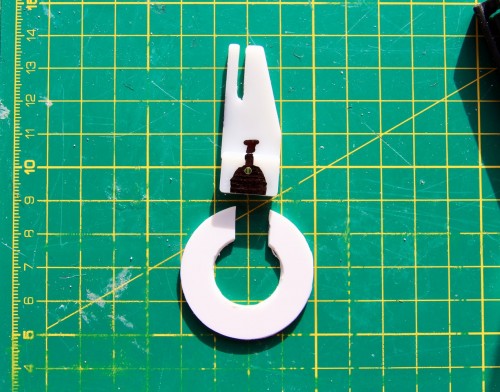

Here I've drawn the rough shape I need to cut out of the elevation arm, in order to bond it to the gun trunnion. The circle of styrene has the the diameter of the trunnion and cut out of it, so as to act as a template for the arm.

The shape of the locking key 1.5mm bolt also appears in the silhouette on the elevation arm. I'm making it up as I go, but in principle, it should work.

..I think

- Mod for elevation arm

The doodle on the arm is a tad crude, but the finished thing should be a precision fit on the trunnion...and hopefully clear up any unintended gobbledegook

. Often there are no accepted terms here for scratch made parts, so it's necessary to approximate them from known engineering terminology..

Really impressed

Really impressed