Re: M4A1 75mm Sherman from BOB

Posted: Sat Jun 04, 2011 5:38 pm

Right I will be getting some joint compound later to try out, will be away for next 36 hours so next update Monday maybe?

Anywho thought I would do a guide of the slightly simplified version of bubbajoexx's bogie mod, the more copies there are of it the less likely it will be lost or forgotten. All recognition goes to him, links to his guide are in one of the older posts in this thread. Also I had to use my phone camera 'cos my girlfriend is away and had the cheek to take her camera with her!

Firstly locate the two screws securing the bogie to the tank;

Once undone remove the bar held by the screws;

bogie can just pulled off tank now, remove the two screws here;

and remove the three screws on the back of the bogie;

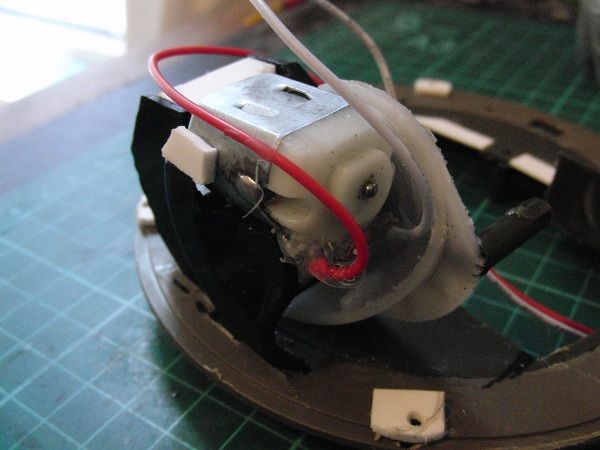

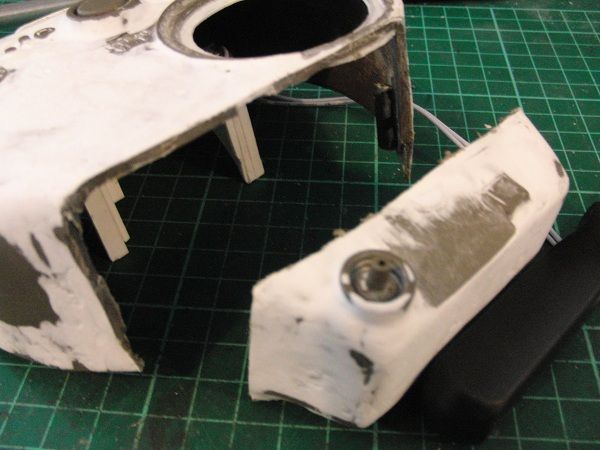

prize apart and this is what you see;

remove the screw for the spring and remove that too;

then carefully seperate the two halves of the wheel clamps;

the rods above can stick and its easy to damage/break the arms. Now I used a rotary tool with cutting disk to do these bits as its quicker, but a craft knife will suffice, the middle section needs to go so cut this on both ends;

try to cut the following staying flush to inner cylindar, this means the wheel arms wont meet and foul in use;

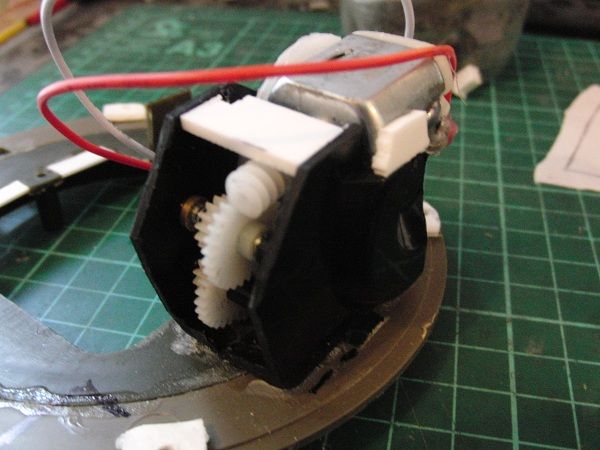

then remove this shaft for lower screw;

and file down the other side of it. Now I managed to get some 2.4mm brass covered steel rod from a fellow moddeler friend at Uni, but you can use any size rod really, so I drilled these shafts out with a 2.5mm drill bit;

and same with the bogie sides;

for the outer side I add a small bit of 1mm styrene sheet and stick in;

without I found that the rods were able to work loose.

The rod I have mentioned, I cut two 30mm and two 20mm lengths;

Place a 30mm rod in the new shaft, and rebuild around wheel;

this lines up following for drilling;

now that adhesive is dry drill the outer bogie side;

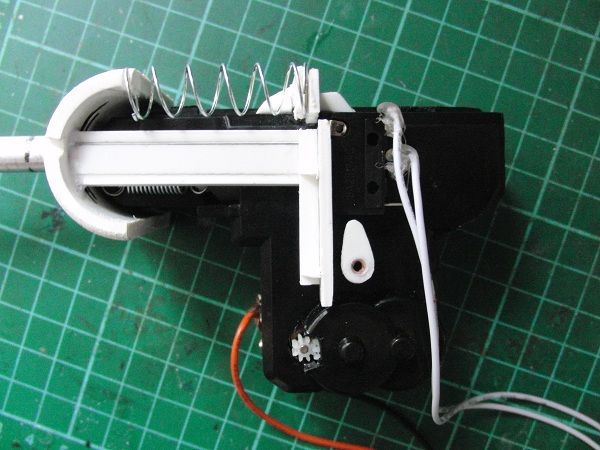

find the spring and try to bend each side out to around 80 degrees apart and put a 90 degree bend at either end;

the further you bend here the stronger the spring action on the wheels, but if you go too far they can ping off.

Now replace spring, place one side of new shaft in the bogie side and hook the spring on to the upper shaft;

replace other bogie side, reassemble, and it should work like this;

If there is any fouling or you cant push down this far, just go back to the bar cutting/seperating stage and file either side down a little.

Thanks for the interest Dave

Dave

Anywho thought I would do a guide of the slightly simplified version of bubbajoexx's bogie mod, the more copies there are of it the less likely it will be lost or forgotten. All recognition goes to him, links to his guide are in one of the older posts in this thread. Also I had to use my phone camera 'cos my girlfriend is away and had the cheek to take her camera with her!

Firstly locate the two screws securing the bogie to the tank;

Once undone remove the bar held by the screws;

bogie can just pulled off tank now, remove the two screws here;

and remove the three screws on the back of the bogie;

prize apart and this is what you see;

remove the screw for the spring and remove that too;

then carefully seperate the two halves of the wheel clamps;

the rods above can stick and its easy to damage/break the arms. Now I used a rotary tool with cutting disk to do these bits as its quicker, but a craft knife will suffice, the middle section needs to go so cut this on both ends;

try to cut the following staying flush to inner cylindar, this means the wheel arms wont meet and foul in use;

then remove this shaft for lower screw;

and file down the other side of it. Now I managed to get some 2.4mm brass covered steel rod from a fellow moddeler friend at Uni, but you can use any size rod really, so I drilled these shafts out with a 2.5mm drill bit;

and same with the bogie sides;

for the outer side I add a small bit of 1mm styrene sheet and stick in;

without I found that the rods were able to work loose.

The rod I have mentioned, I cut two 30mm and two 20mm lengths;

Place a 30mm rod in the new shaft, and rebuild around wheel;

this lines up following for drilling;

now that adhesive is dry drill the outer bogie side;

find the spring and try to bend each side out to around 80 degrees apart and put a 90 degree bend at either end;

the further you bend here the stronger the spring action on the wheels, but if you go too far they can ping off.

Now replace spring, place one side of new shaft in the bogie side and hook the spring on to the upper shaft;

replace other bogie side, reassemble, and it should work like this;

If there is any fouling or you cant push down this far, just go back to the bar cutting/seperating stage and file either side down a little.

Thanks for the interest