Excellent suggestion Atcttge!atcttge wrote:Great progress.

Any plans to make a mounting plate for the gearbox? Just so make things at that area even more durable? It'll also add weight if you're making it out of aluminium or steel. I'd like to put a mounting plate for the gearbox, but couldn't find one.

I had considered doing just that for several reasons:

1. Plastic mounting post not desirable for long term maintainability. I am concerned about thread wear and being easily stripped out during normal removal and installation of mounting screws.

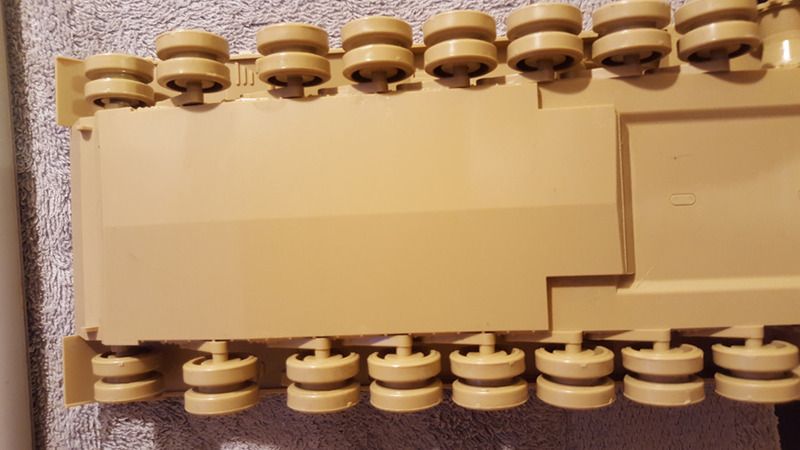

2. Mounting post easily damaged especially with the use of the “Axle Supports”. I have found that to remove or install a gearbox both must be unmounted so that they can be moved all the way outboard and tipped up and aft to accommodate getting the opposite GB in or out. I worry about snapping the threaded end off of the aft most mounting post. However even with the mounting plate both GBs will have to be unmounted to allow removal and installation of one or both for the same reason.

I would use a piece of aluminum with a minimum thickness of .125”though I think .187” would be better giving a solid thickness for tapping and yield a good number of threads.

How to mount the plate is another matter. I am ruling out the existing mounting post as they align with the mount holes in the GB. I suppose a mounting “block” could be attached central to the GBs and anchored up through the hull. The plate would attach to the block then the existing mount holes in the GBs would be used to attach to the plate. The block would have to be relatively thick to allow tapping into both the upper and lower faces and to set the plated at the proper height. Shims made of peel-able shim stock could be used to properly align the drive shafts to the axle supports for “fine” tuning. This could be a great improvement; being able to actually control the alignment of the drive shift.

I like the idea and it bears do more scrutiny!

Cheers,

Barry

]

]

l]

l]