not that the tracks derailing once in awhile isn't cool

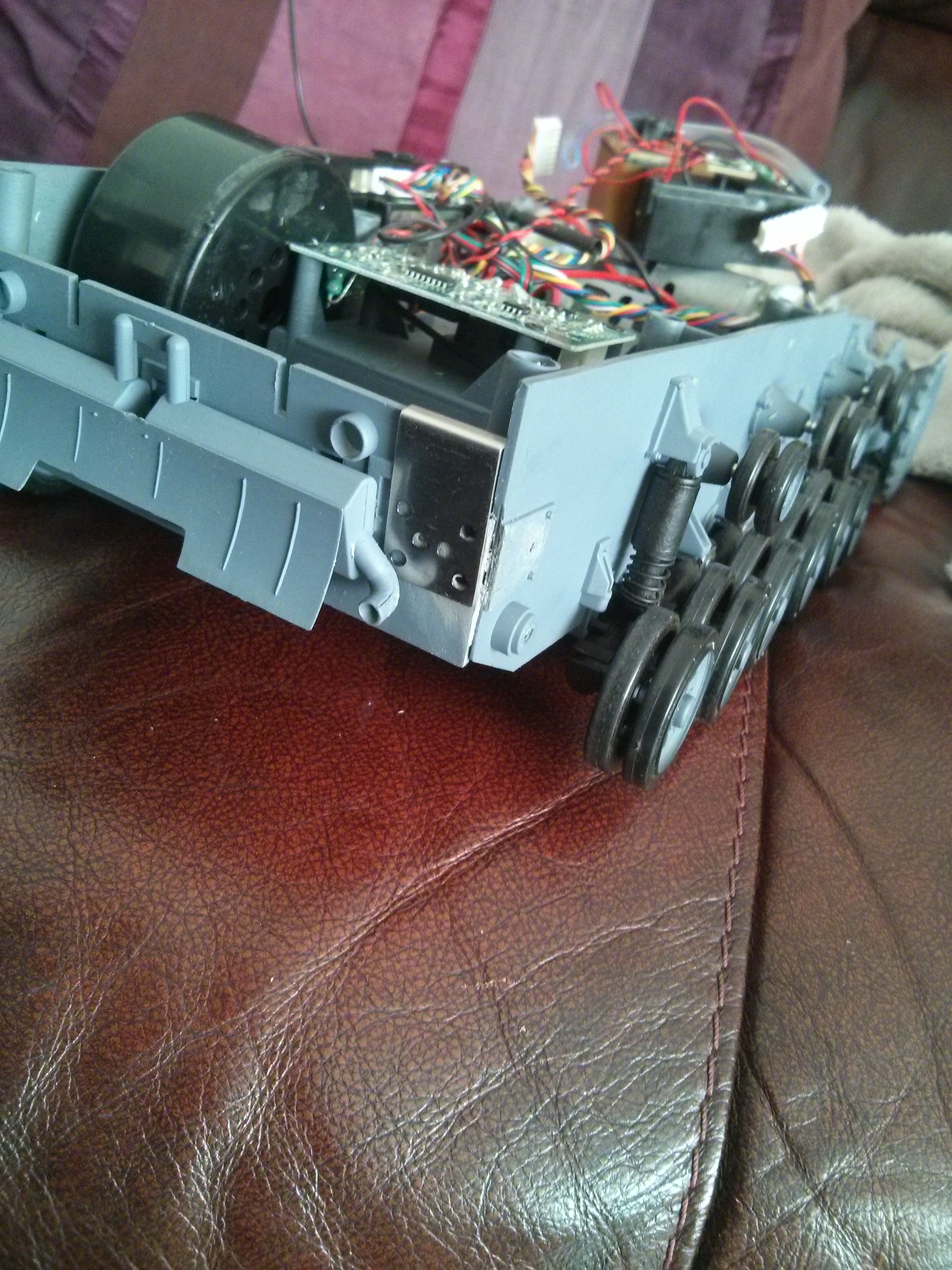

and it adds to the smooth performance and endurance of the gearbox and motors

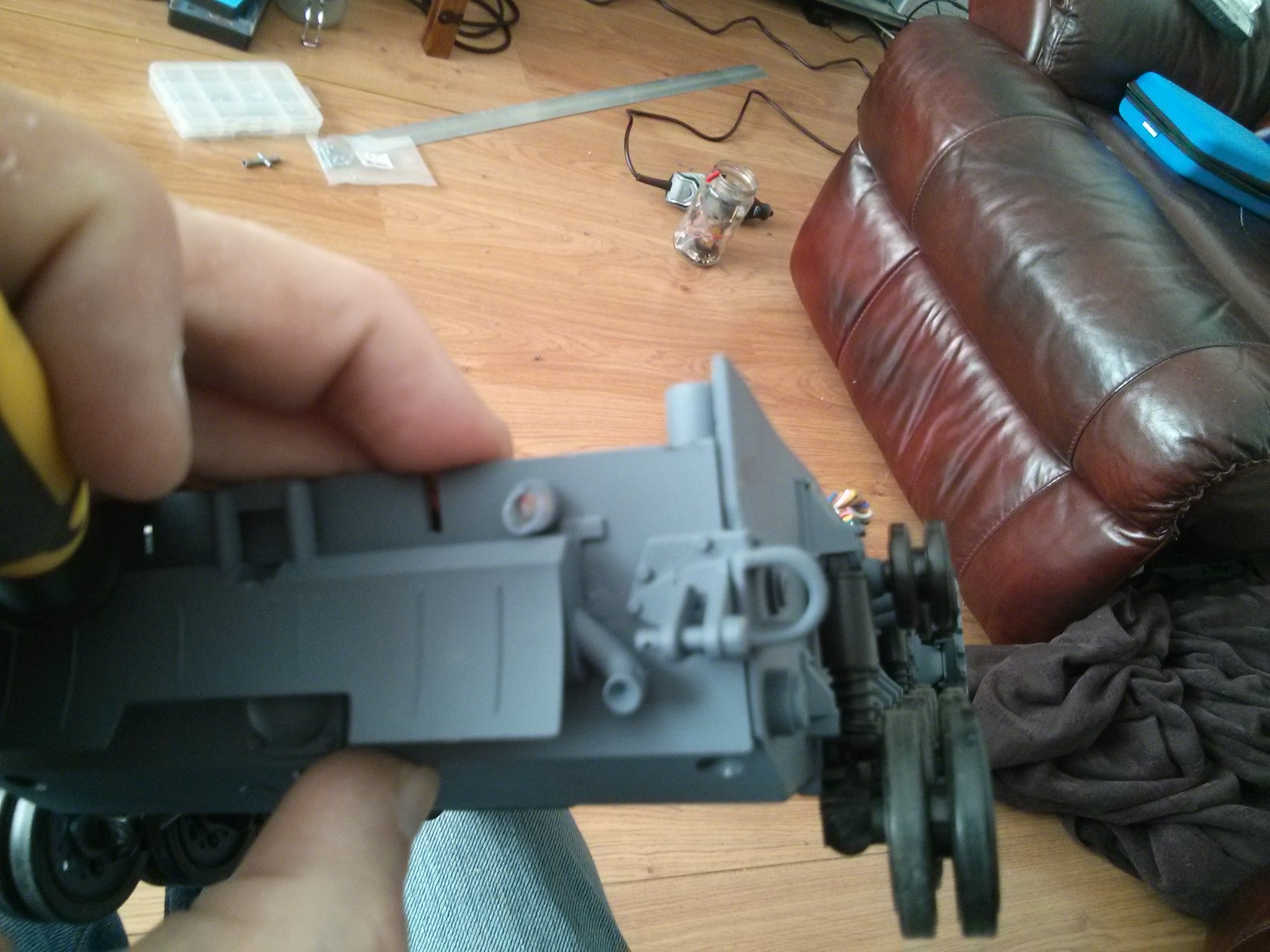

So a set of those metal aftermarket tensioners are almost a must.... you can try using the original plastic parts... but the metal idler arm is much stronger

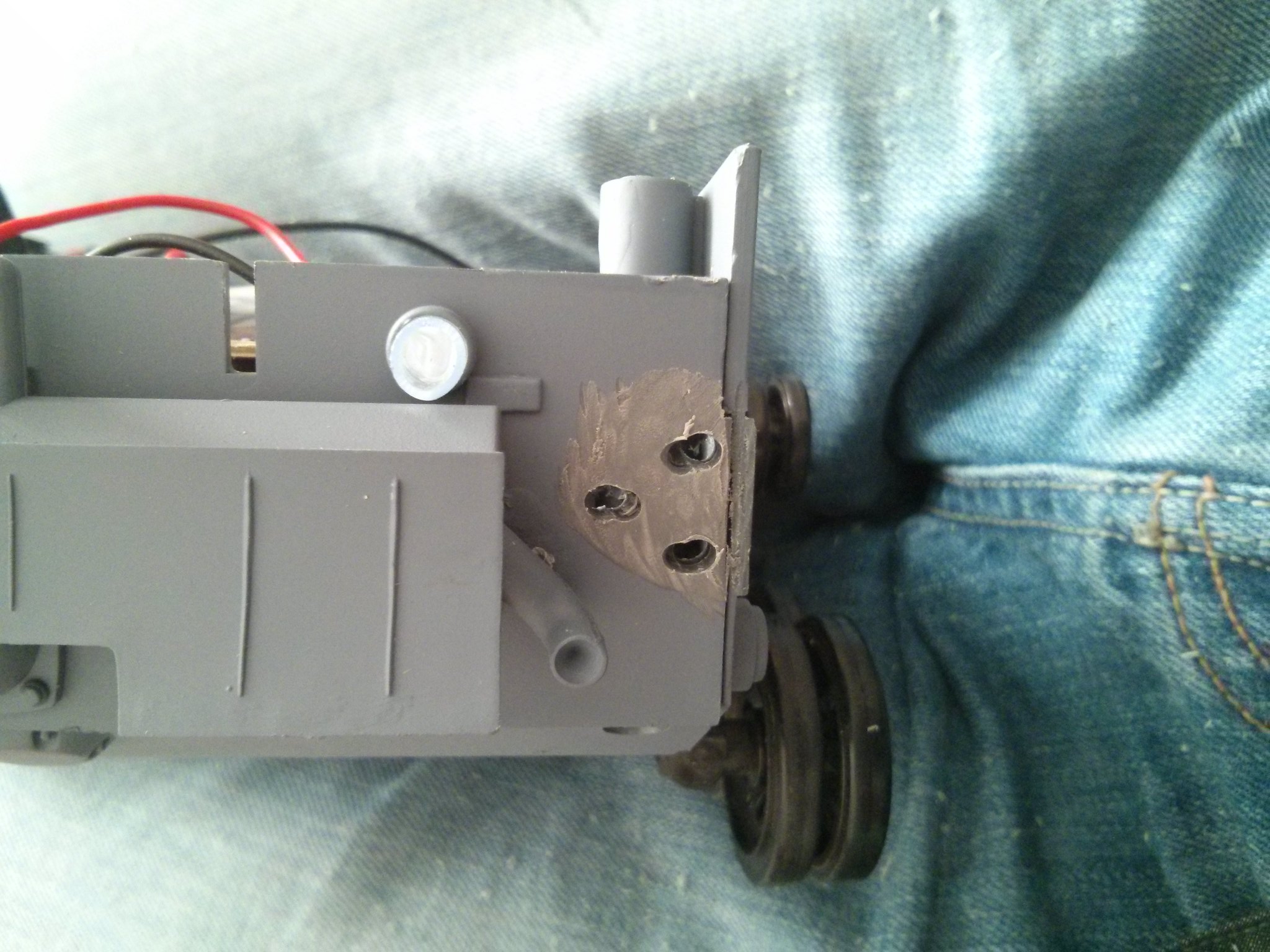

When i installed it on my Stug ... i found i did not need to grind off the original support casting on the hull... What i did instead was to plug the hole where the plastic tensioner slips through with a piece of over sized sprue .... drilled a hole in the center to accommodate the tension screw...then use the rest of the parts in the tensioner kit to finish the job....

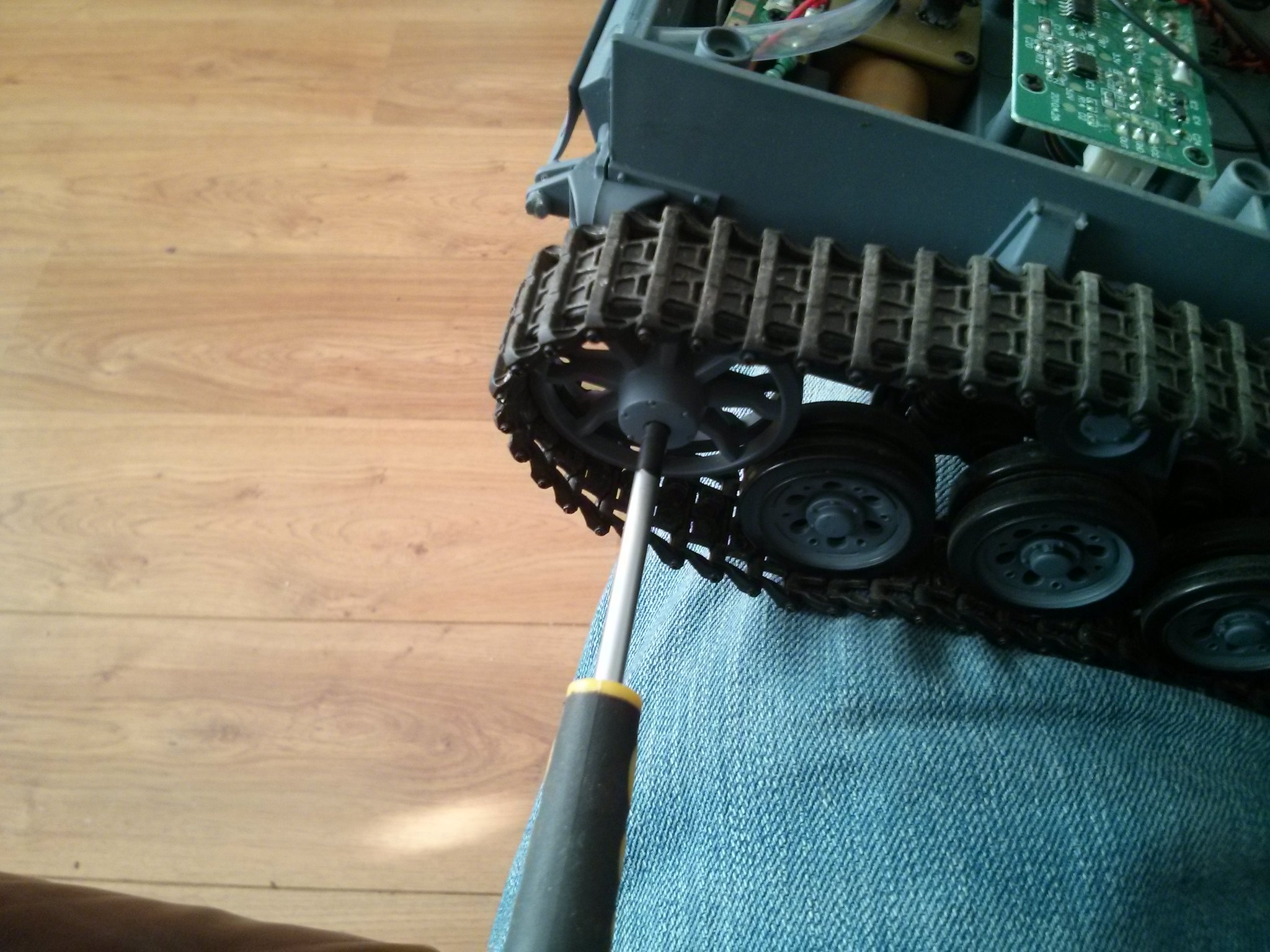

The only other hitch you might come up against is the Heng long Idlers.... since the tensioner is designed primarily for the Taigen...there is no provision for the gaping hole Heng long has in their idlers ....what i did to solve that problem was separate the halves of the idler... drill and insert 6mm metal bushings {( airsoft gearbox bushings) the nylon bushings work... but will slowly loosen the idler wheel screws} inside the idler half that has the hole for the axle screw...do not... and i do mean do not... drill from the exposed side... the hole will be too large.. and will compromise the integrity of the idler

Upon closing the two halves of the idlers find an appropriate length screw ... a little lock tight and you should be ready to run

sorry no pictures ...