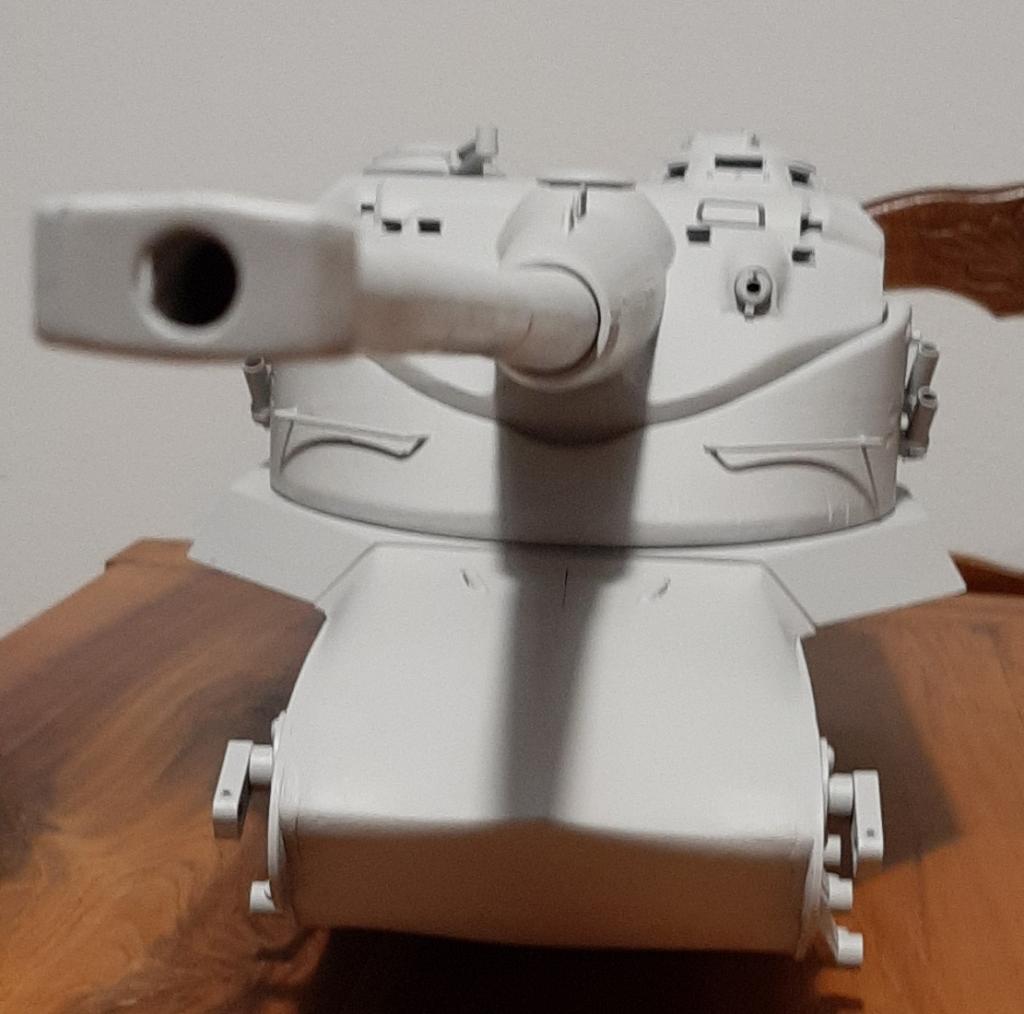

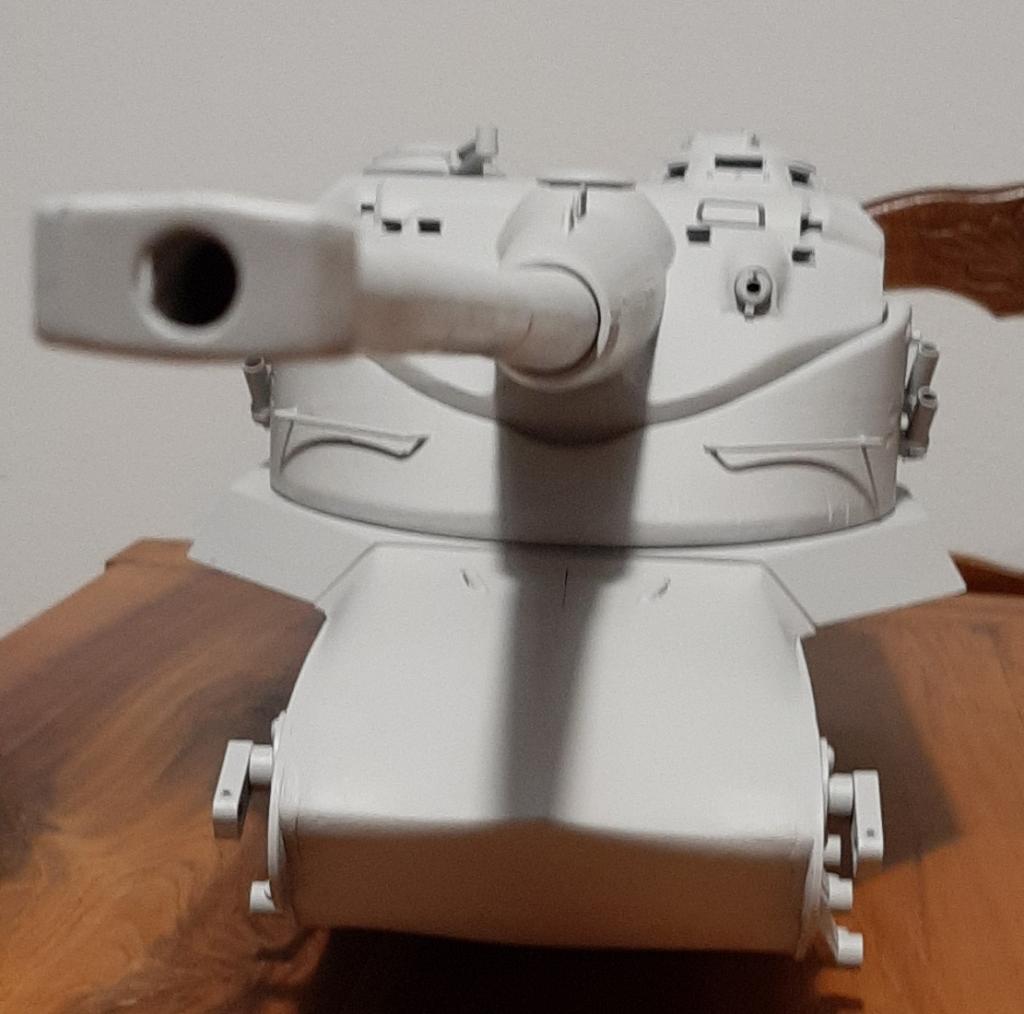

here is my 3D printed AMX 50 120 surbaissé, it is in progress, I move slowly, but I will tell you about the evolution…

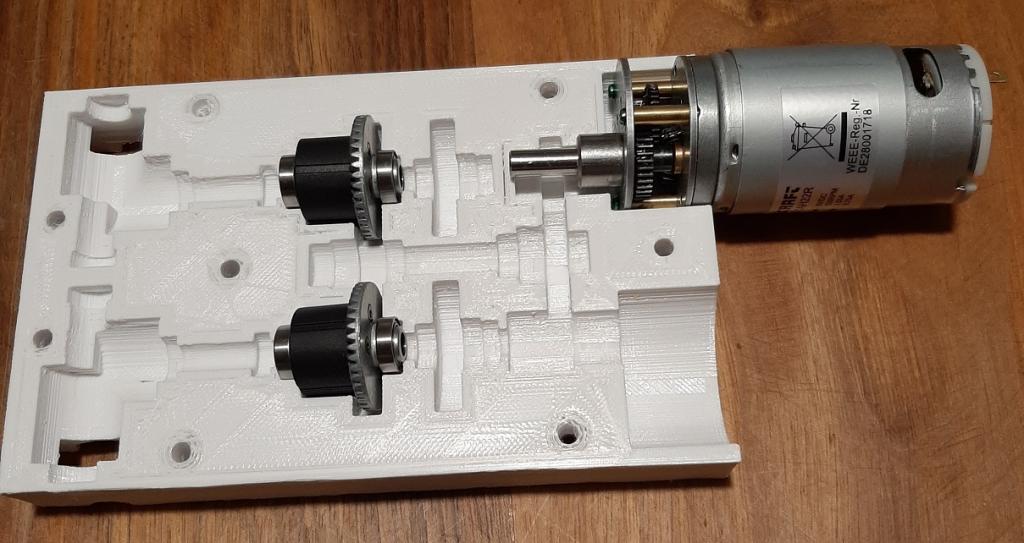

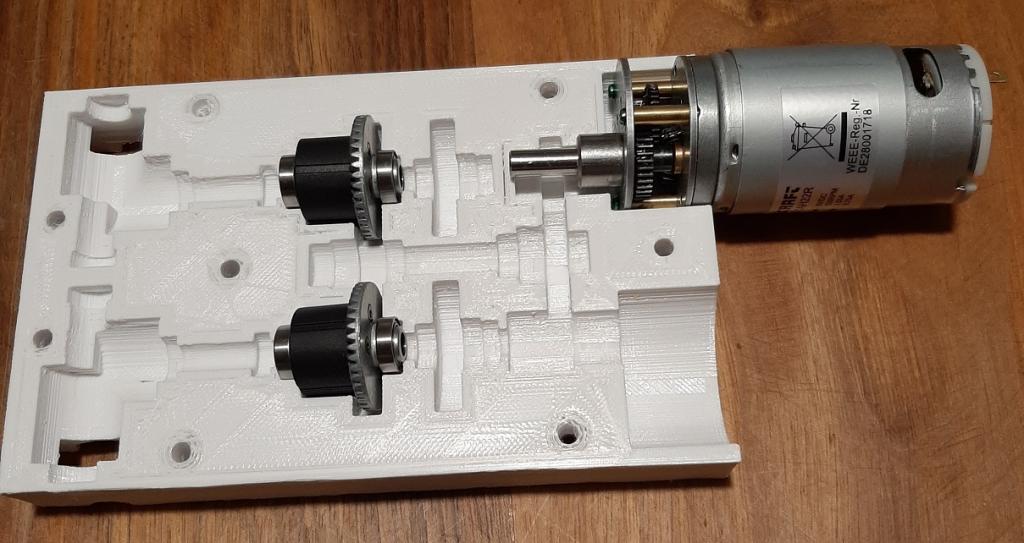

And the first part of the gearbox:

Every part is printed except the swing arms and torsion bars (Tamyia)orntar wrote:It's very impressive! What hull are you using, or did you print that too?

And what is gong on with that gear box? Looks cool!

You really have to look up the French forum he linked to. So much more info and the online translator does a reasonable job for us non French speaking rc tank enthusiasts.43rdRecceReg wrote:Really impressiveHave you already added surfacer in the first two pics, or did the printer produce that almost unblemished finish? It's a great printer if it did, and you're a great finisher if it didn't.

Indeed, and I think I'm right in saying ABS a far better plastic than PLA.. and probably easier to bond.MITCH wrote:My 3d printer is an Anet A8 upgraded. It is a low cost machine... but abs is an easy to sand material

I have the same printer! Great project you have there.MITCH wrote:My 3d printer is an Anet A8 upgraded. It is a low cost machine... but abs is an easy to sand material