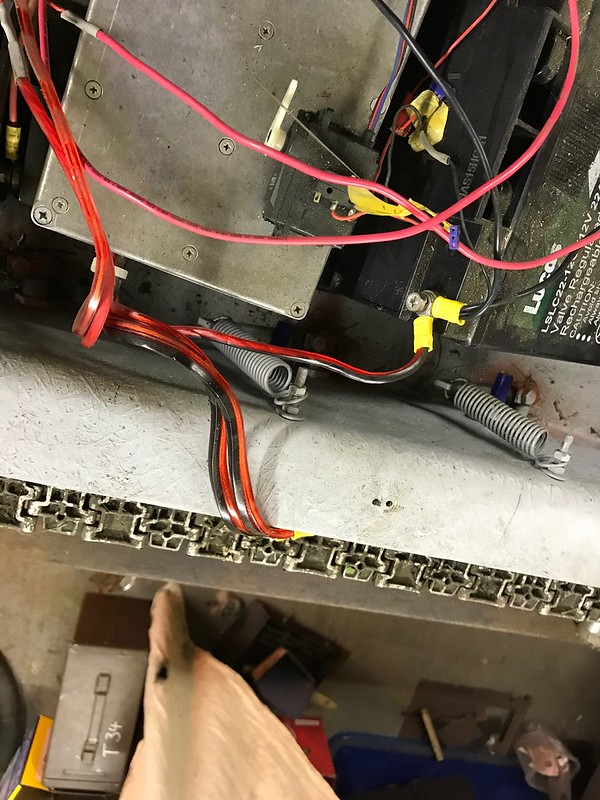

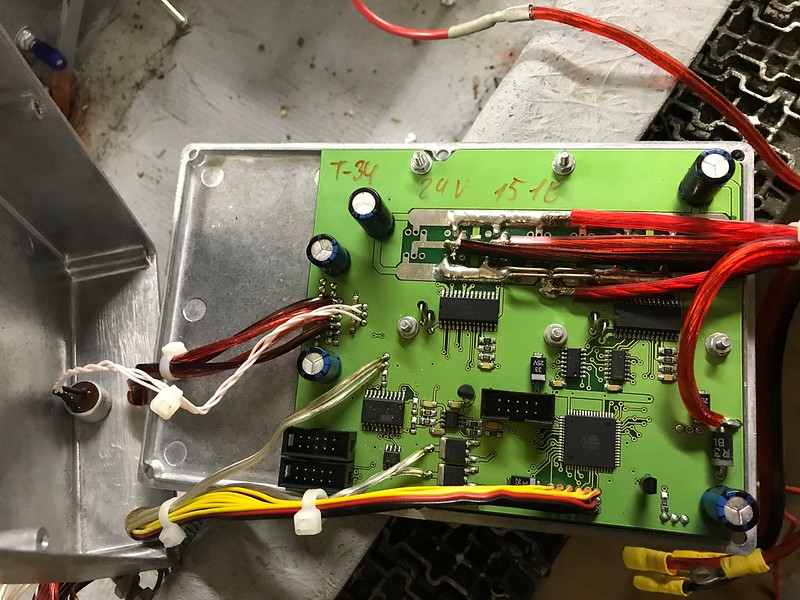

The inside:

When running something didn't seem right so with investigation I noticed the tracks were catching on the rear drive wheels, the rollers on the wheels were fine but the tracks caught on the top points

So after some sanding I settled on this

Which was massive improvement after the track tension was reduced.

Next was the suspension the 5mm bolts were mainly bent and out of align

SO replaced with 6mm and some silicone tube damping

This made the tank a lot better again, it now runs without the tracks trying to jump off the wheels.

Next on the list is to fix the alignment of the road wheels but someone has welded the swing arm levers to the swing arms but not just a small tack its a full on weld so will need a lot of grinding to sort that, so I may at the same time make a CNC chassis in 6mm steel plate as I have a workshop capable of such stuff.

Hence the "Here we go" bit.

I can see so many ways to improve this from wiring to sounds etc, but at least its running a lot better already.